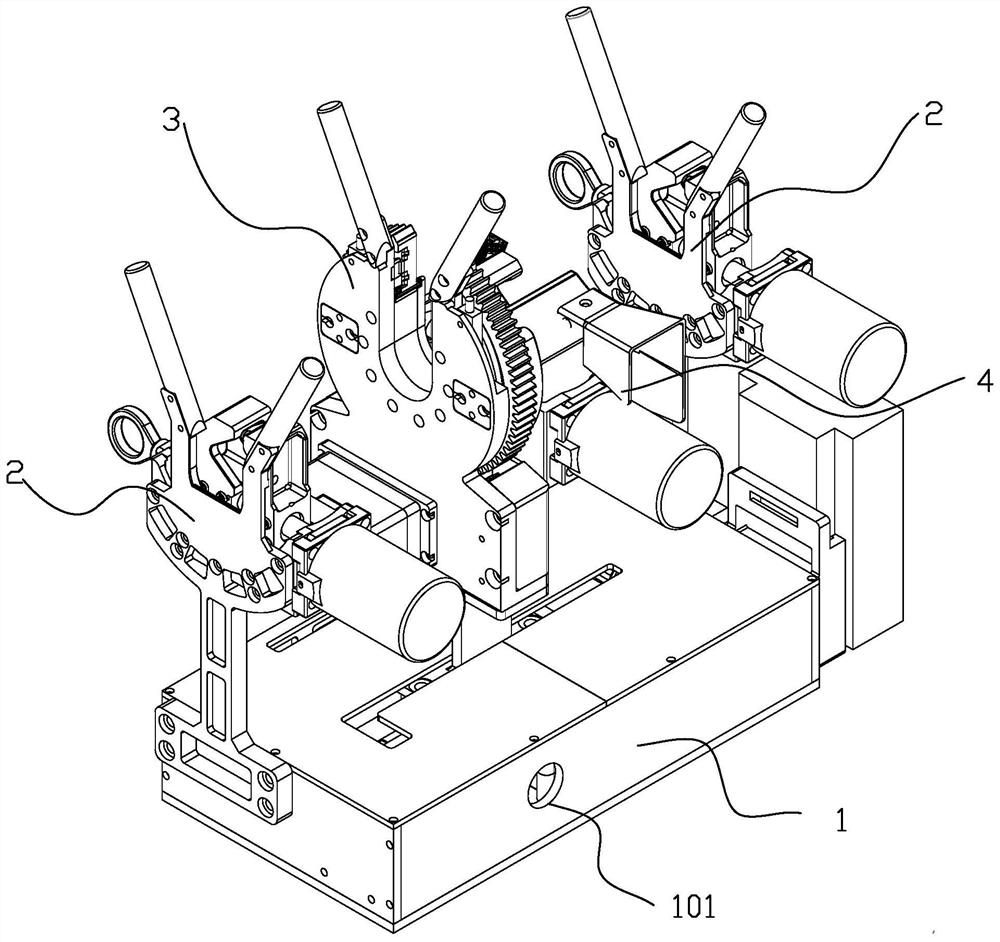

Power distribution network hot-line work special-purpose wire stripping tool

A live working and distribution network technology, applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problems of difficult stripping, affecting cutting and stripping operations, and use restrictions, and achieve the effect of avoiding incomplete stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

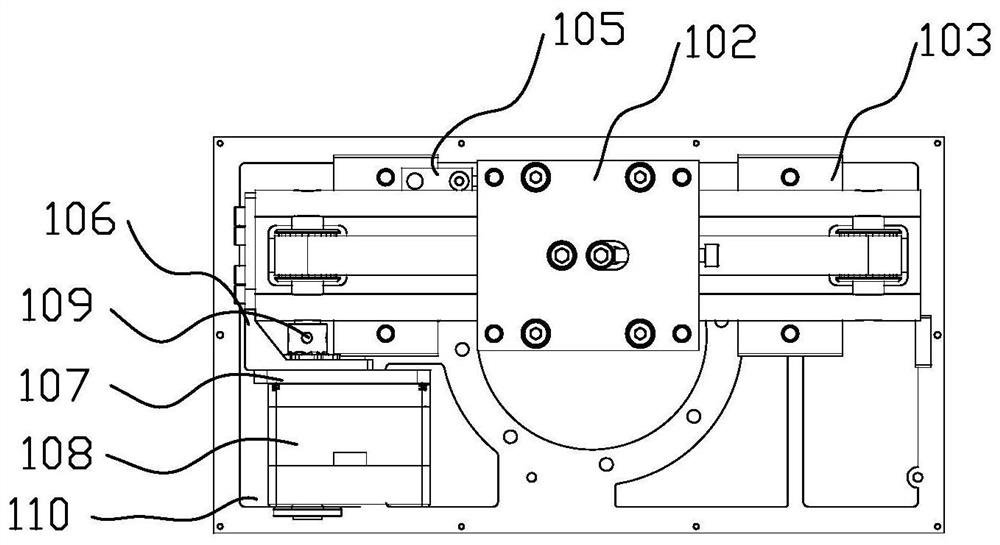

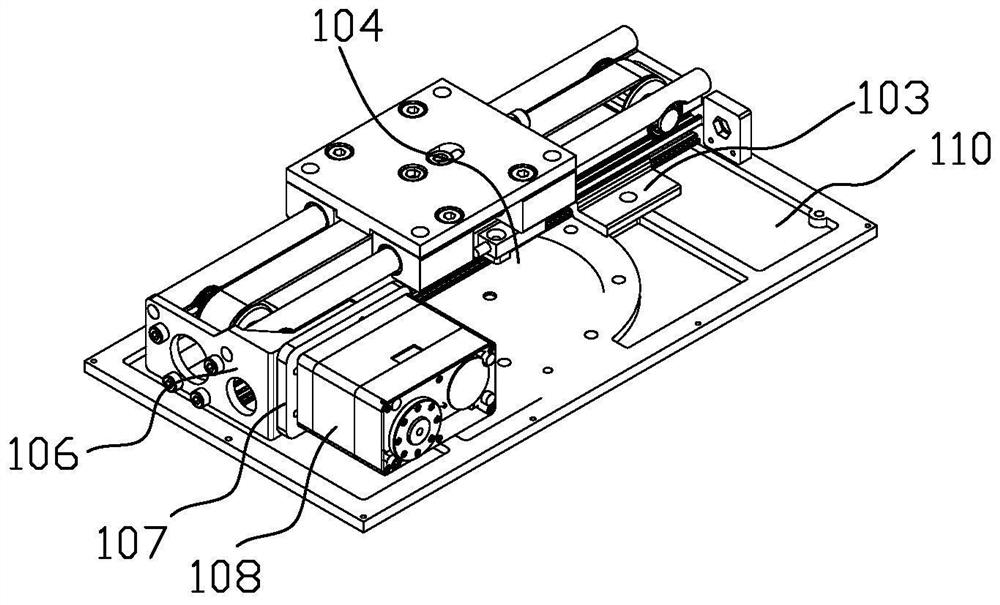

[0046] Such as Figure 12 , Figure 13 As shown, the main line holding unit 2 includes a support frame 201, a material guide rod A202, a material guide rod B203, a holding support frame 204, a two-way lead screw 1 205, a bearing cover 206, a lead screw nut A207, and a slider A208 , lead screw nut B209, slider B210, motor mounting plate 212, tightening motor one 213, tightening motor protective shell 214, auxiliary ring one 215, linear guide rail one 216, and the clamping support frame 204 is installed on the support by screws On the frame 201, the two-way lead screw 1 205 is installed on the support frame 204 through bearings. One side of the lead screw is left-handed, and the other side is right-handed. Through the rotation of the lead screw, the synchronization of the slider is realized and the direction is opposite. movement; through the forward rotation and reverse rotation of the lead screw, the tightening and loosening of the clamping unit of the main line is realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com