Process for producing hydroxyalkyltriethylenediamine compound, and catalyst composition for the production of polyurethane resin using the hydroxyalkyltriethylenediamine compound

A technology of hydroxyalkyltriethylenediamine and hydroxytriethylenediamine, which is used in the manufacture of hydroxyalkyltriethylenediamine compounds and the field of catalyst compositions for the manufacture of polyurethane resins using the compounds, Can solve the problem of odor without any discussion, decrease in curability, insufficient physical properties such as polyurethane resin hardness, etc.

Inactive Publication Date: 2011-05-04

TOSOH CORP

View PDF20 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is indeed effective in reducing the odor of the final resin product, however, since these reactive catalysts deteriorate in the activity of the resinization reaction (reaction of polyol and isocyanate), there is a problem that curability decreases

[0021] In addition, the method of using the above-mentioned crosslinking agent is effective for reducing the odor of the final resin product and improving the working environment when producing polyurethane resin, but the physical properties such as hardness of polyurethane resin are not sufficient.

[0022] Furthermore, a method of using an amine compound having a hydroxyl group, a primary amino group, and a secondary amino group in the molecule as a catalyst for producing rigid polyurethane foam has also been proposed (for example, see Patent Document 8 and Patent Document 9), but the purpose of these methods is to improve The fluidity and thermal conductivity of the foam, but there is no discussion on improving the odor problem

[0023] On the other hand, although metal-based compounds do not cause the problem of odor or deterioration of other materials such as the above-mentioned tertiary amine compounds, if the metal-based compounds are used alone, as described above, the productivity, physical properties, and formability will be affected. deterioration, and there are also environmental problems caused by heavy metal residues in products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example 1

preparation example 2

preparation example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

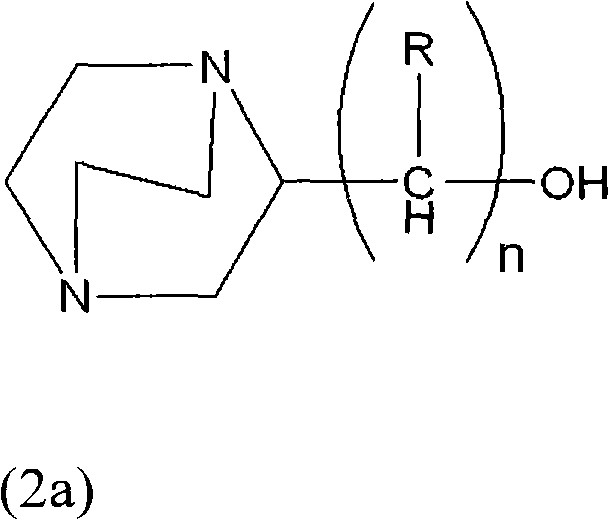

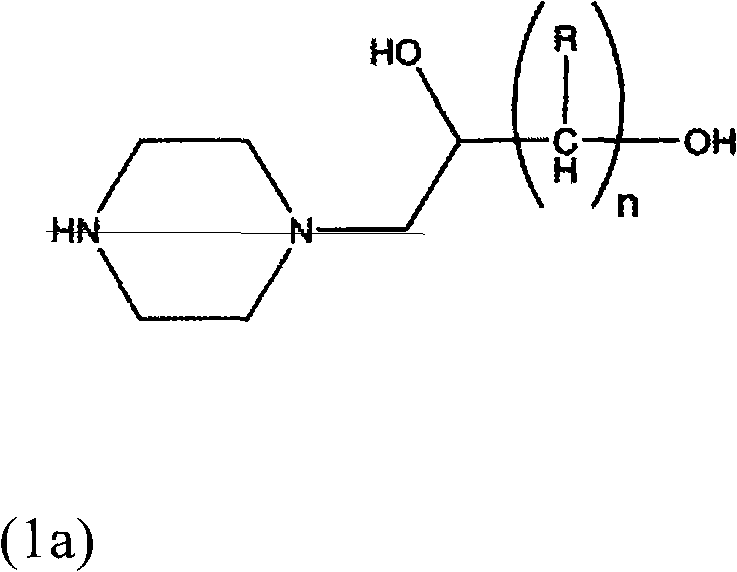

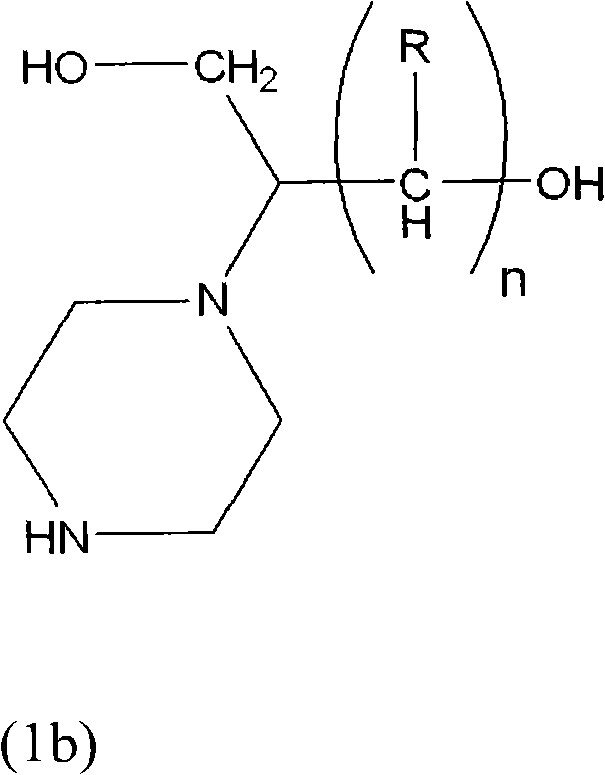

Disclosed is a process for producing a hydroxyalkyltriethylenediamine compound or hydroxytriethylenediamine without multi-stage reaction steps through a small number of steps in a simple manner. Also disclosed is a novel catalyst composition that can provide a polyurethane product produced with high productivity and moldability without causing problems with odor and environment. Further disclosed is a process for producing a polyurethane resin using the catalyst composition. A hydroxyalkyltriethylenediamine compound or hydroxytriethylenediamine is produced by subjecting, for example, a mono-substituted dihydroxyalkylpiperazine compound and / or a di-substituted hydroxyalkylpiperazine compound to an intramolecular dehydrocondensation in the presence of an acid catalyst. Further, a polyurethane resin is produced by using a catalyst composition comprising, for example, a hydroxyalkyltriethylenediamine compound or hydroxytriethylenediamine (A) and an amine compound (B) having one or at least two substituents, in the molecule thereof, selected from the group consisting of a hydroxy group, a primary amino group, and a secondary amino group or a tertiary amine compound (C) having a value of [foaming reaction rate constant / resinification reaction rate constant] of 0.5 or more.

Description

technical field [0001] The present invention relates to (1) a method for producing hydroxyalkyltriethylenediamines or hydroxytriethylenediamine, (2) a method for producing hydroxyalkylpiperazines and / or hydroxypiperazines, (3) A catalyst composition of alkyltriethylenediamine or hydroxytriethylenediamine for producing a polyurethane resin, and a method for producing a polyurethane resin using the catalyst composition. Background technique [0002] Hydroxyalkyltriethylenediamines or hydroxytriethylenediamines are compounds that can be used as pharmaceutical and agricultural chemical intermediates, catalysts for organic synthesis, chemical adsorbents, antibacterial agents, and the like. [0003] In addition, hydroxyalkylpiperazines are compounds useful as pharmaceutical and agricultural chemical intermediates, catalysts for organic synthesis, chemical adsorbents, antibacterial agents, and the like. [0004] In addition, in the case of catalyst compositions containing hydroxya...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D487/08C07D295/08C07B61/00

CPCC07D295/08C07D487/08C08G18/1825C08G18/2063C08G18/7621C08G2110/0083

Inventor 德本胜美铃木孝生木曾浩之高桥义宏玉野丰

Owner TOSOH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com