Single-phase self-start permanent magnet synchronous motor

A permanent magnet synchronous motor, self-starting technology, applied in synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, shapes/styles/structures of winding conductors, etc., can solve complex controllers and sensors, Increased manufacturing costs and other issues, resulting in improved running smoothness, improved starting performance, and reduced vibration and noise levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

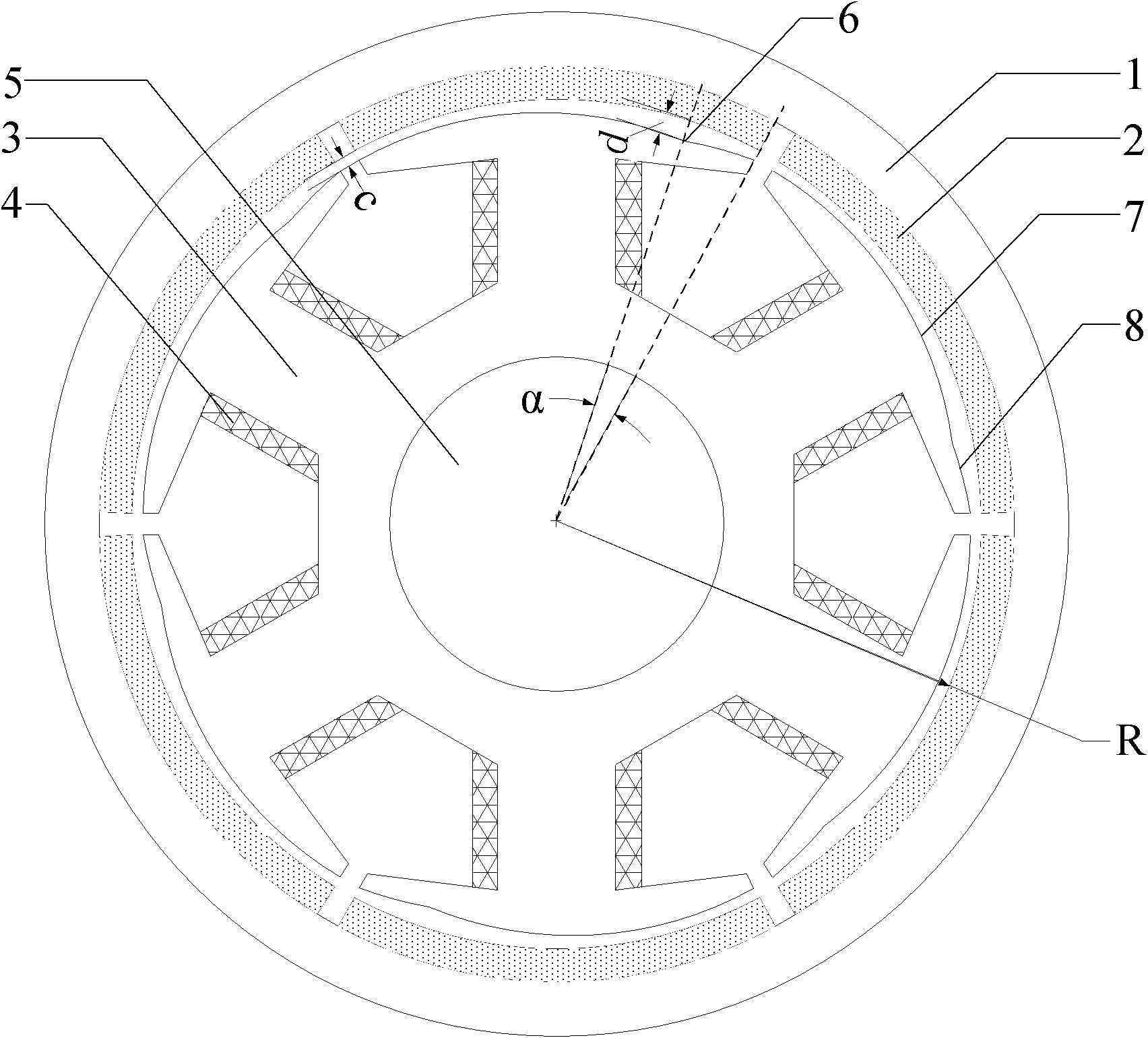

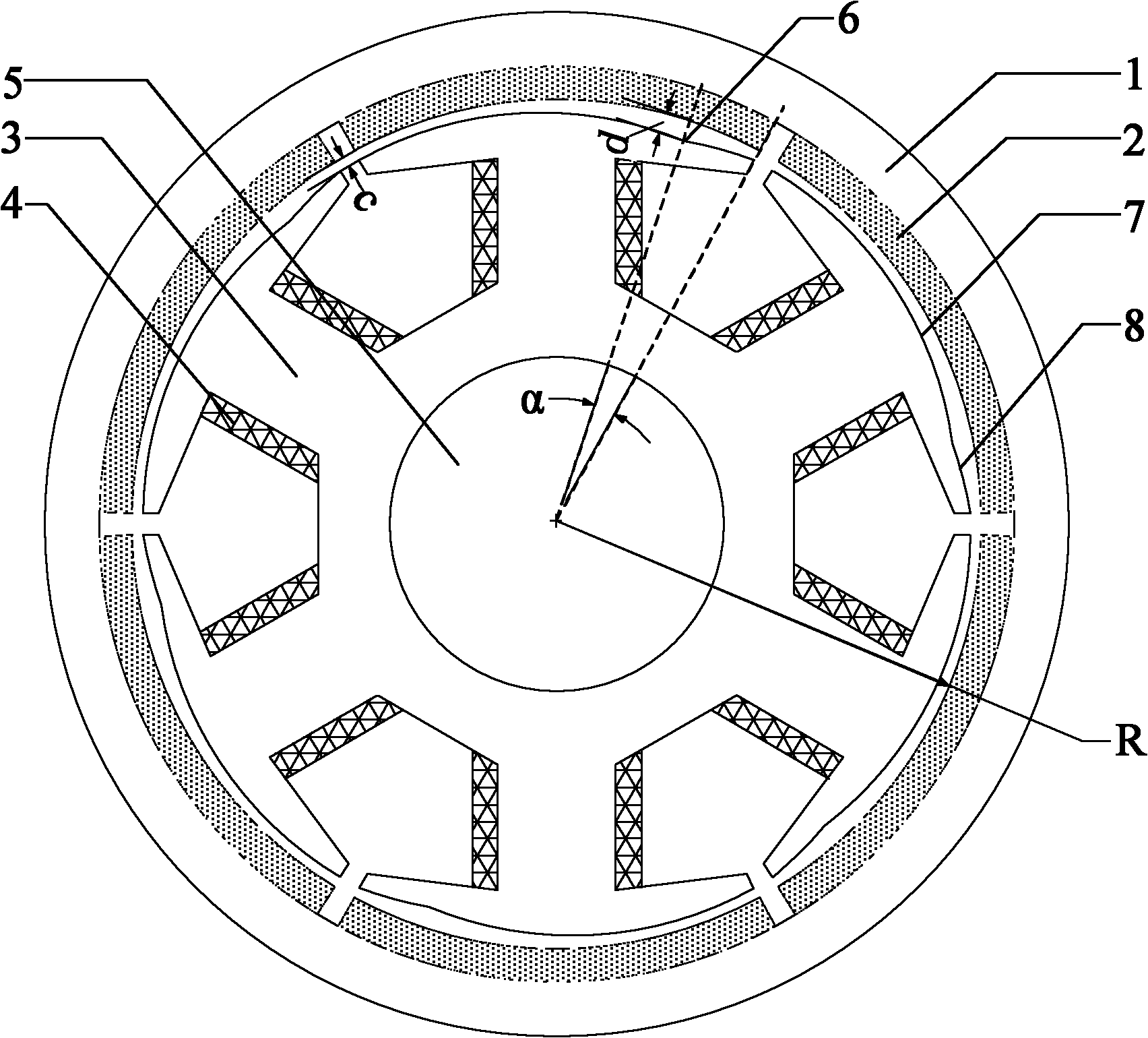

[0020] As shown in the drawings, a single-phase self-starting permanent magnet synchronous motor of the present invention includes a rotor yoke 1, a permanent magnet 2, a stator shaft hole 5 and a stator 3. The rotor yoke 1 is an outer rotor structure, and the rotor yoke 1 uses a magnetically conductive Made of steel, the permanent magnet 2 is pasted on the inner surface of the rotor yoke 1, and the N pole and S pole are spaced apart. The inner diameter of the permanent magnet is R. The inner side of the permanent magnet 2 is a stator, and the stator includes a stator iron core 3 and a single-phase stator winding 4, and the number of teeth of the stator is the same as the number of magnetic poles of the rotor (both are six). The surface of the teeth of the stator core 3 is a curved surface formed by connecting the first arc 7 and the second arc 8 , and an air gap exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com