Inhibition ethanediol antifreezing fluid

An antifreeze and inhibitory technology, which is applied in the field of antifreeze to achieve low cost, stable performance, and improved antibacterial and antifouling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

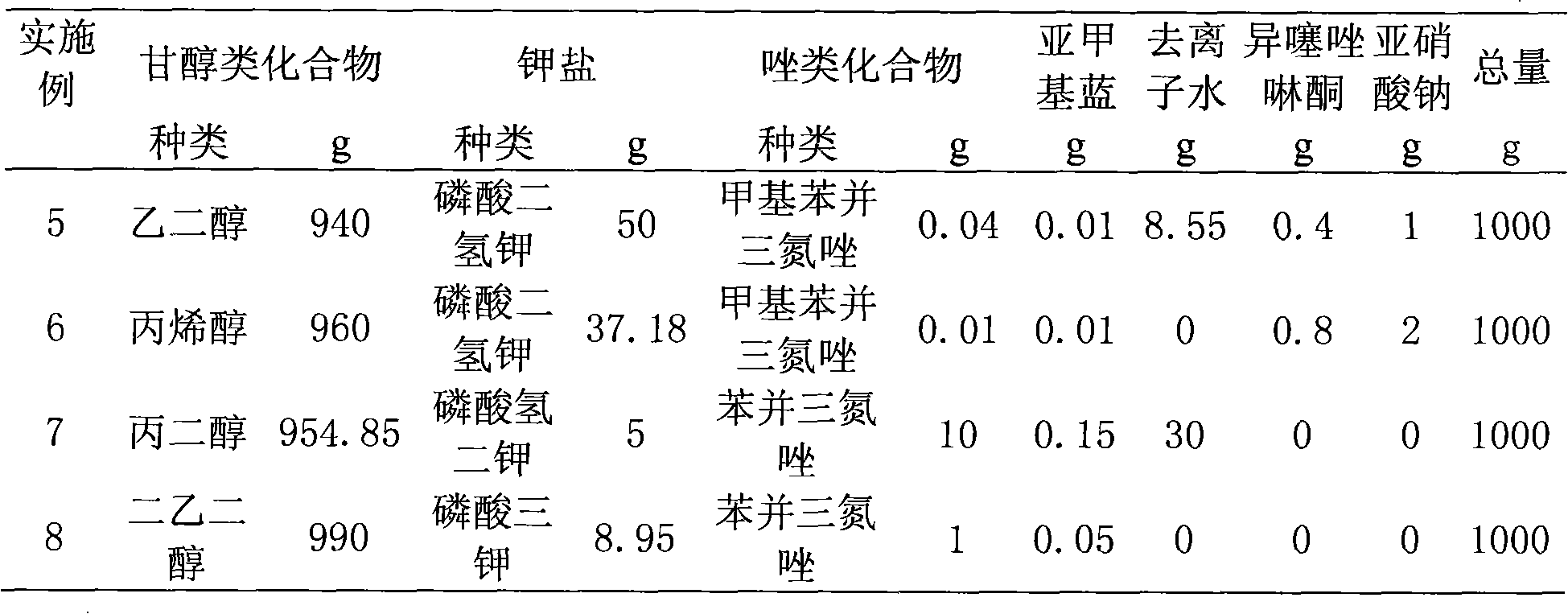

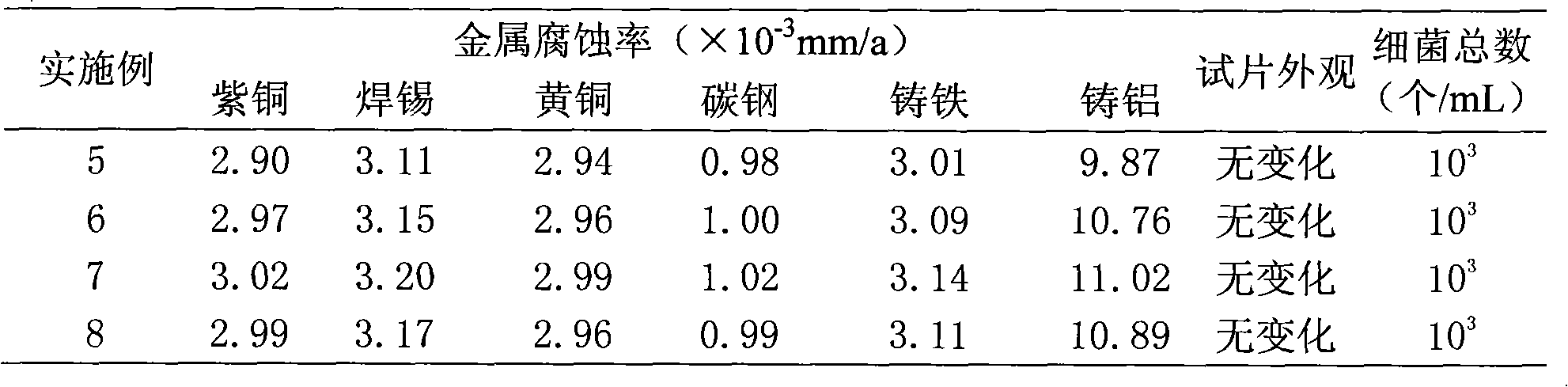

Examples

Embodiment 1

[0030] Formula: 960g of ethylene glycol, 30g of hydrogen phosphate, 0.02g of azole compounds (benzazole), 0.1g of water -soluble dye (nail -foundation blue), and 9.88g of de -ion water.

[0031] After mixing and dissolving the quantitative ethylene glycol, hydrogen phosphate, pyropide and triazorazole, and exfoliating water, add the nails of the nails for coloring and stir until evenly.

[0032] 2. Mix with 1: 4 with the prepaid ethylene glycol -freezing solution with 1: 4.The corrosion rate of the six metal slices is: Copper 2.84 × 10 -3 mm / a, solder 3.07 × 10 -3 mm / a, brass 2.82 × 10 -3 mm / a, carbon steel 0.91 × 10 -3 mm / a, cast iron 2.90 × 10 -3 mm / a, cast aluminum 9.53 × 10 -3 mm / a.After the experiment, the color of each metal piece has not changed, and there is no attachment. The total number of bacteria of the antifreeze after the experiment is 10 2 One / ml.

[0033] Example 2

Embodiment 2

[0035] Formula: ethylene glycol 960g, hydrogen phosphate di potassium 25g, isopedazoleol 0.4g, sodium nitrite 1g, azole compound (benzazole) 0.02g, water -soluble dye (Asian metal blue) 0.1g, de -ion water water13.48g.

[0036]After mixing and dissolving the quantitative ethylene glycol, hydrogen phosphate, glycopritoline, sodium nitrite, phenyl triazorazole, and deodorded water, add the nails of the nails for coloring and stir until evenly.

[0037] 2. Mix with 1: 4 with the prepaid ethylene glycol -freezing solution with 1: 4.The corrosion rate of the six metal slices is: Copper 2.76 × 10 -3 mm / a, solder 3.01 × 10 -3 mm / a, brass 2.79 × 10 -3 mm / a, carbon steel 0.72 × 10 -3 mm / a, cast iron 2.69 × 10 -3 mm / a, cast aluminum 8.94 × 10 -3 mm / a.After the experiment, the color of each metal piece has not changed, and there is no attachment. The total number of bacteria of the antifreeze after the experiment is 10 1 One / ml.

[0038] Example 3

Embodiment 3

[0040] Formula: ethylene glycol 960g, hydrogen phosphate di potassium 25g, isopedazoleol 0.4g, sodium nitrite 1g, azole compound (benzazole) 0.02g, water -soluble dye (Asian metal blue) 0.1g, de -ion water water13.48g.

[0041] After mixing and dissolving the quantitative ethylene glycol, hydrogen phosphate, glycopritoline, sodium nitrite, phenyl triazorazole, and deodorded water, add the nails of the nails for coloring and stir until evenly.

[0042] 2. Mix with 1: 3 with the prepaid ethylene glycol refrigeration liquid with 1: 3.The corrosion rate of the six metal slices is: Copper 2.55 × 10 -3 mm / a, solder 2.86 × 10 -3 mm / a, brass 2.57 × 10 -3 mm / a, carbon steel 0.67 × 10 -3 mm / a, cast iron 2.47 × 10 -3 mm / a, cast aluminum 8.01 × 10 -3 mm / a.After the experiment, the color of each metal piece has not changed, and there is no attachment. The total number of bacteria of the antifreeze after the experiment is 10 1 One / ml.

[0043] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com