Polyvinyl alcohol (PVA) foamed collodion cotton with vegetable starch and bamboo carbon powder and preparation method thereof

A plant-based, bamboo carbon powder technology, applied in the field of foam collodion, can solve the problems of cost increase, practical impact, and must be discarded, and achieve the effect of prolonged service life and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

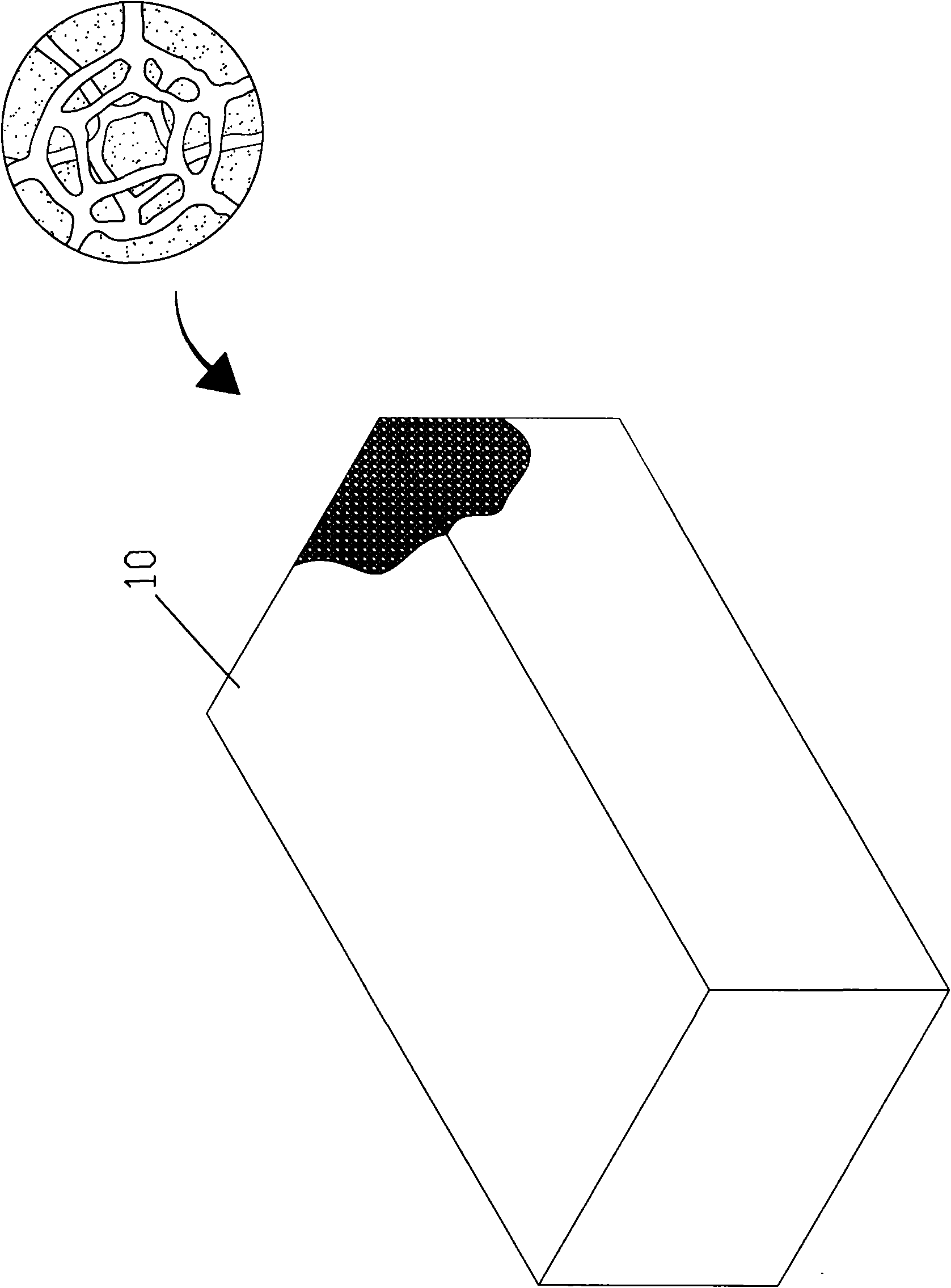

[0014] With regard to the structure and composition of the present invention, as well as the functions and advantages that can be produced, a preferred embodiment of the present invention will be described in detail as follows in conjunction with the drawings.

[0015] The invention provides a structural improvement of PVA (polyvinyl alcohol) foam, especially through the innovative composition of the structure, so that it can further improve the hydrophilicity of the PVA (polyvinyl alcohol) material. The cleaning performance of dirt and dirt and its toughness and strength.

[0016] With regard to the structural composition, technical means and effect of the present invention, it will be further described in detail with examples in conjunction with the drawings:

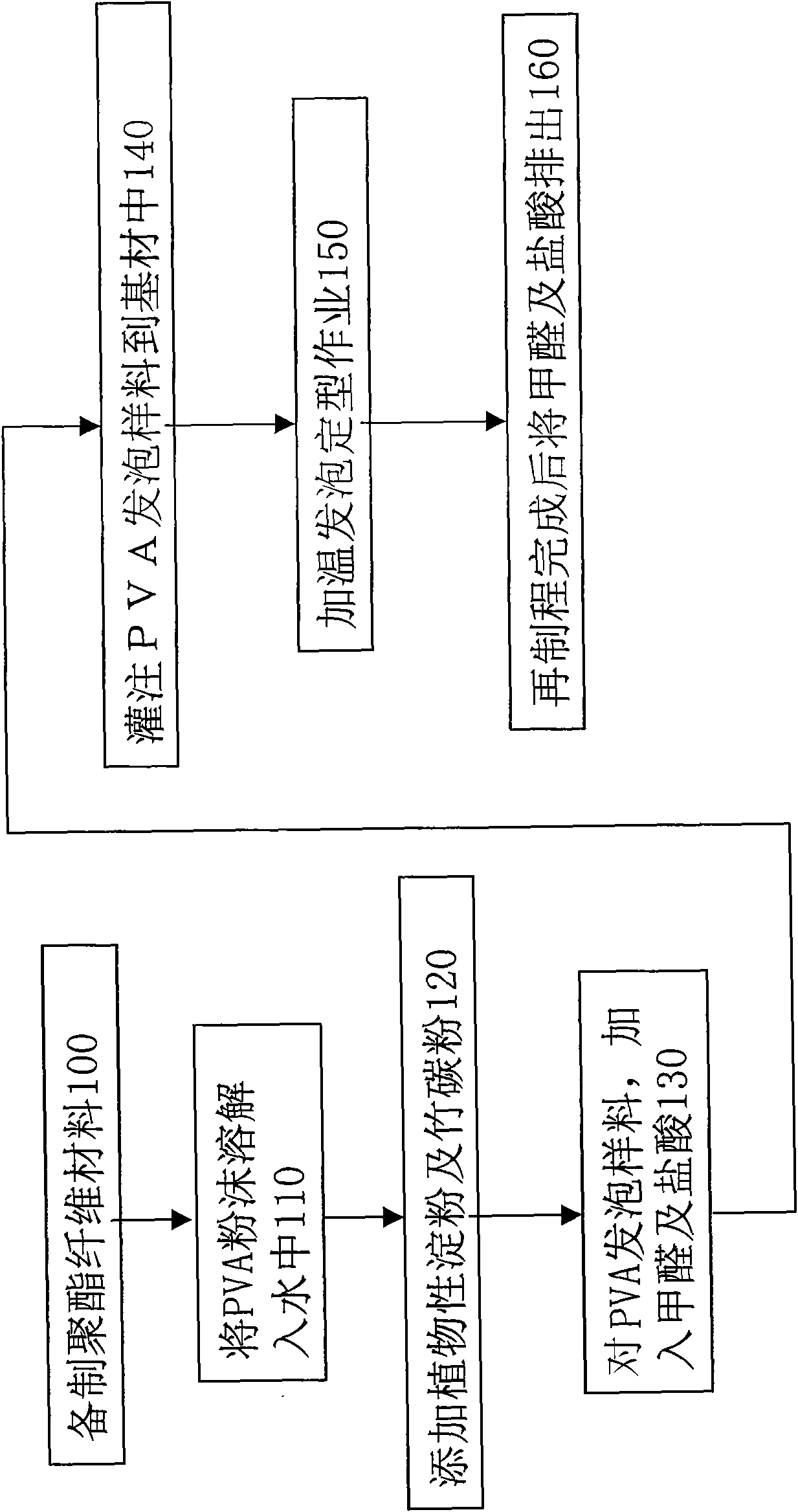

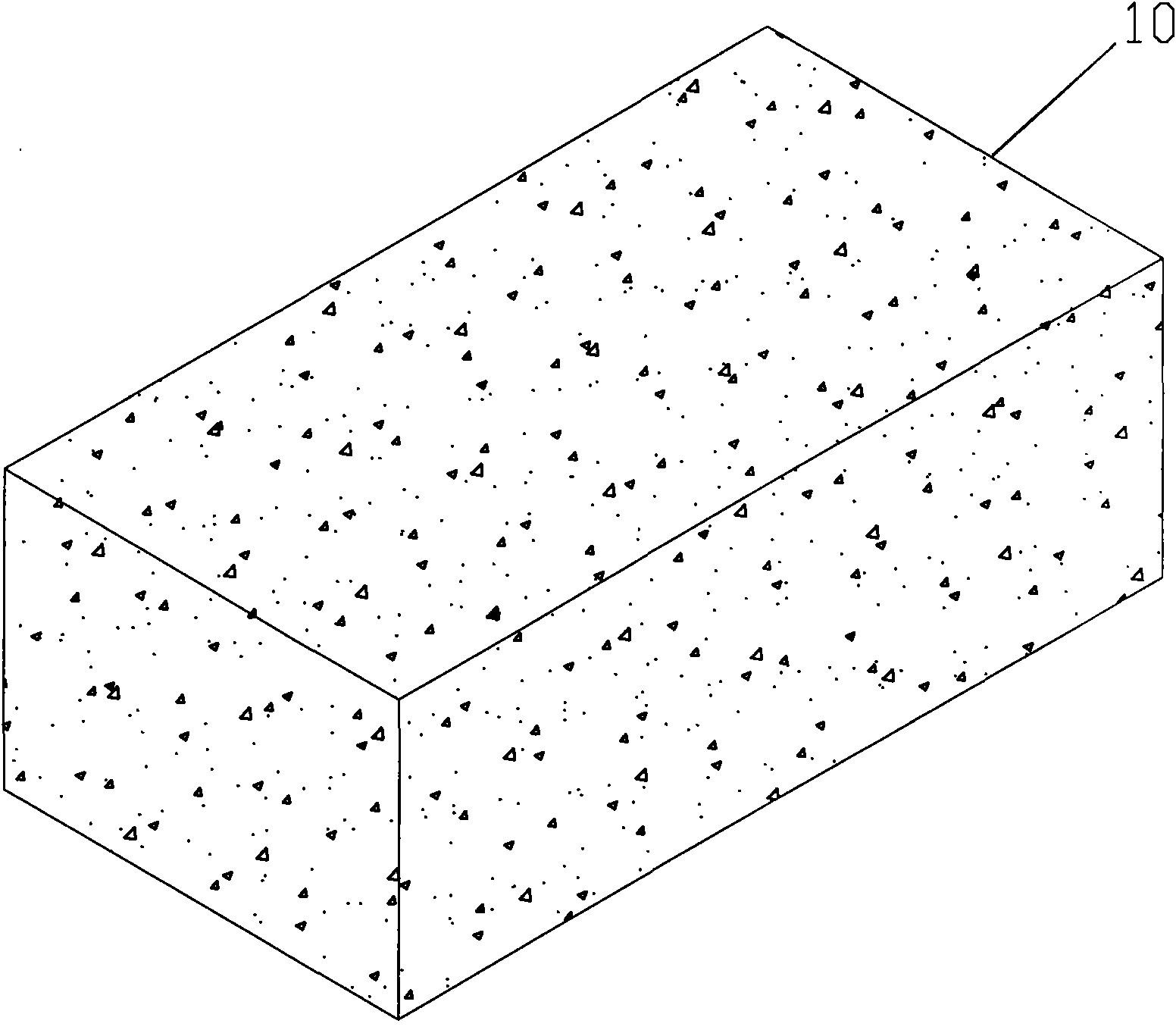

[0017] First, if figure 1 As shown, it shows the operation flow diagram of the present invention. In terms of structural design, the present invention mainly has a polyester fiber material with a penetrating pore str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com