Black master batch and preparation method thereof

A technology of black masterbatch and carbon black, which is applied in the field of high-concentration black masterbatch and its preparation, can solve the problems of poor dispersibility of carbon melanin, low blackness and brightness, and low concentration of black masterbatch, and achieves good dyeing effect, The effect of high brightness and high carbon black concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

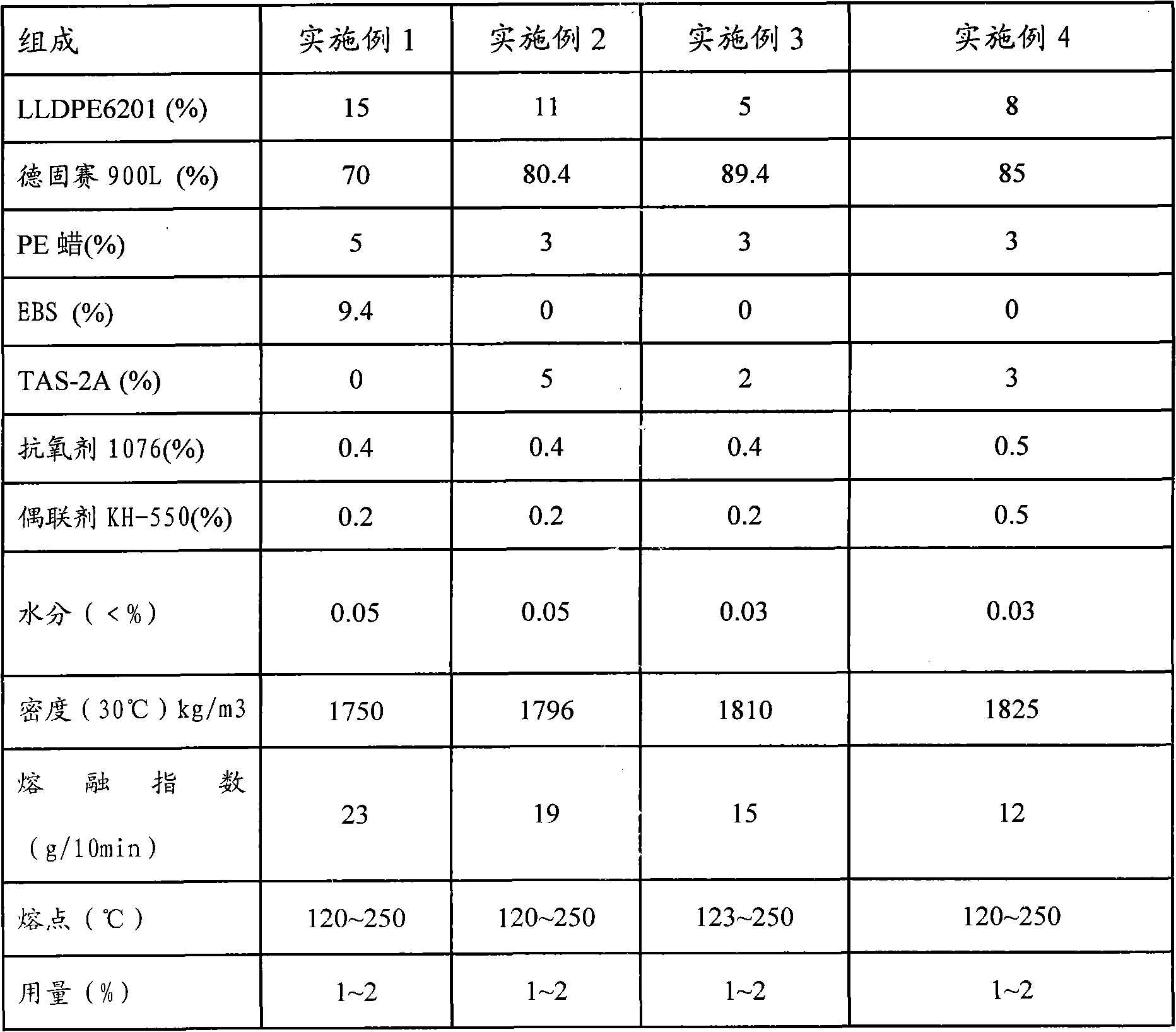

Embodiment 1

[0024] Formulation: LLDPE6201 15%

[0025] Degussa 900L 70%

[0026] PE wax 5%

[0027] EBS 9.4%

[0028] Antioxidant 1076 0.4%

[0029] Coupling agent KH-550 0.2%

[0030] Preparation method: first pre-mix according to the formula ratio, then mix evenly in a high-speed mixer (speed 1500r / min), then add to an internal mixer, banbury at 150°C for 10 minutes, and crush the obtained material with a crushing equipment. Finally, put the pulverized material into a twin-screw extruder to extrude, heat-cut in water, cool, and dry to obtain the required masterbatch.

[0031] The process is: twin-screw first stage temperature 180-200°C, second stage temperature 180-200°C, third stage temperature 180-200°C, fourth stage temperature 180-200°C, fifth stage temperature 170-180°C, sixth stage temperature 170-180°C, The seven-stage temperature is 170-180, the eight-stage temperature is 170-180, and the die head temperature is 190-210.

Embodiment 2

[0033] Formulation: LLDPE6201 11%

[0034] Degussa 900L 80.4%

[0035] PE wax 3%

[0036] TAS-2A 5%

[0037] Antioxidant 1076 0.4%

[0038] Coupling agent KH-550 0.2%

[0039] Preparation method: first pre-mix according to the formula ratio, then mix evenly in a high-speed mixer (speed 1500r / min), then add to an internal mixer, banbury at 150°C for 10 minutes, and crush the obtained material with a crushing equipment. Finally, put the pulverized material into a twin-screw extruder to extrude, heat-cut in water, cool, and dry to obtain the required masterbatch.

Embodiment 3

[0041] Formulation: LLDPE620 15%

[0042] Degussa 900L 89.4%

[0043] PE wax 3%

[0044] TAS-2A 2%

[0045] Antioxidant 1076 0.4%

[0046] Coupling agent KH-550 0.2%

[0047] Preparation method: first pre-mix according to the formula ratio, then mix evenly in a high-speed mixer (speed 1500r / min), then add to an internal mixer, banbury at 150°C for 10 minutes, and crush the obtained material with a crushing equipment. Finally, put the pulverized material into a twin-screw extruder to extrude, heat-cut in water, cool, and dry to obtain the required masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com