Method for comprehensively utilizing chlor-alkali salt sludge

A technology for chlor-alkali salt and salt mud is applied in the field of comprehensive utilization of chlor-alkali salt mud, which can solve the problems of wasting transportation costs and being unfavorable to environmental protection, and achieves the effects of low equipment requirements and simple production process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

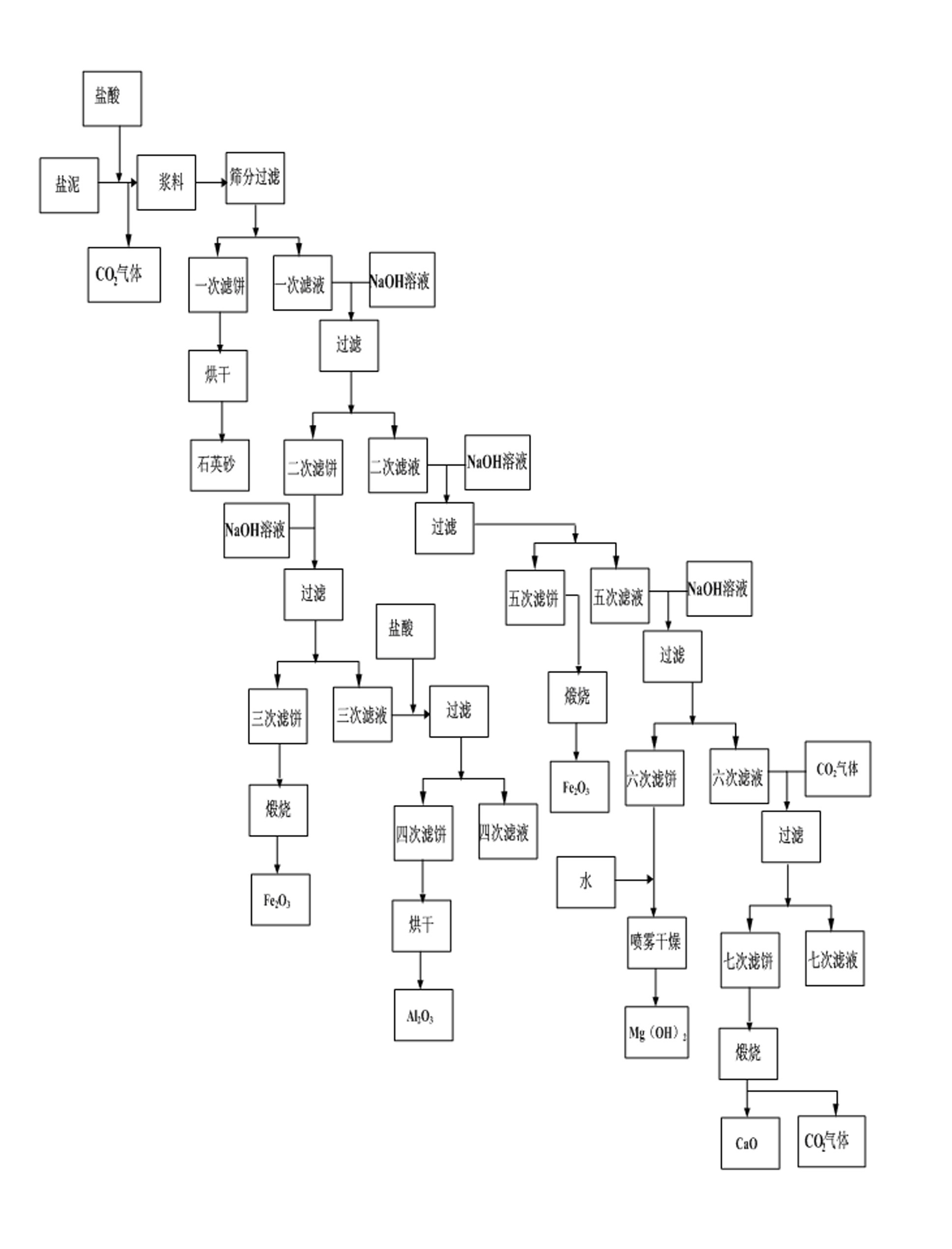

Image

Examples

Embodiment 1

[0048] The hydrochloric acid concentration that adopts is 0.1mol / L, and the NaOH solution concentration that adopts is 0.5mol / L;

[0049] Mix the chlor-alkali salt mud with water and stir evenly, the mixing ratio is chlor-alkali salt mud by weight: water=1:5, then add hydrochloric acid to adjust the pH=1 of the mixture, obtain the slurry, and generate CO 2 the gas is recovered;

[0050] Filter the slurry with a 100-mesh sieve to obtain a filter cake and a filtrate, and dry the filter cake to remove moisture to obtain quartz sand;

[0051] Add NaOH solution to the primary filtrate and stir evenly, adjust the pH=4 of the primary filtrate, then filter under stirring conditions to obtain secondary filter cake and secondary filtrate;

[0052] Add NaOH solution to the secondary filter cake and stir evenly, adjust the pH of the secondary filter cake to 9, and then filter under stirring conditions to obtain the third filter cake and the third filtrate, and calcinate the third filter ...

Embodiment 2

[0059] The hydrochloric acid concentration that adopts is 0.2mol / L, and the NaOH solution concentration that adopts is 0.4mol / L;

[0060] Mix chlor-alkali salt mud and water and stir evenly, the mixing ratio is chlor-alkali salt mud: water = 1:10 by weight, then add hydrochloric acid to adjust the pH of the mixture to 2, obtain slurry, and generate CO at the same time 2 the gas is recovered;

[0061] Filter the slurry with a 160-mesh sieve to obtain a filter cake and a filtrate, and dry the filter cake to remove moisture to obtain quartz sand;

[0062] Add NaOH solution to the primary filtrate and stir evenly, adjust the pH=5 of the primary filtrate, then filter under stirring conditions to obtain secondary filter cake and secondary filtrate;

[0063] Add NaOH solution to the secondary filter cake and stir evenly, adjust the pH of the secondary filter cake to 10, and then filter under stirring conditions to obtain the third filter cake and the third filtrate, and calcinate th...

Embodiment 3

[0070] The hydrochloric acid concentration that adopts is 0.4mol / L, and the NaOH solution concentration that adopts is 0.3mol / L;

[0071] Mix chlor-alkali salt mud with water and stir evenly, the mixing ratio is chlor-alkali salt mud: water = 1:15 by weight, then add hydrochloric acid to adjust the pH of the mixture to 3, obtain slurry, and generate CO 2 the gas is recovered;

[0072] Filter the slurry with a 160-mesh sieve to obtain a filter cake and a filtrate, and dry the filter cake to remove moisture to obtain quartz sand;

[0073] Add NaOH solution to the primary filtrate and stir evenly, adjust the pH=6 of the primary filtrate, then filter under stirring conditions to obtain secondary filter cake and secondary filtrate;

[0074] Add NaOH solution to the secondary filter cake and stir evenly, adjust the pH of the secondary filter cake to 11, and then filter under stirring conditions to obtain the third filter cake and the third filtrate, and calcinate the third filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com