Copper-based dispersive bimetallic self-lubricating material and method for preparing self-lubricating base material

A technology of self-lubricating materials and bimetals, which is applied in the field of preparation of copper-based dispersed bimetallic self-lubricating materials and self-lubricating substrates, can solve the problems of short wear life and high friction coefficient, and achieve low friction coefficient and long durability The effect of increasing the grinding life and increasing the self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

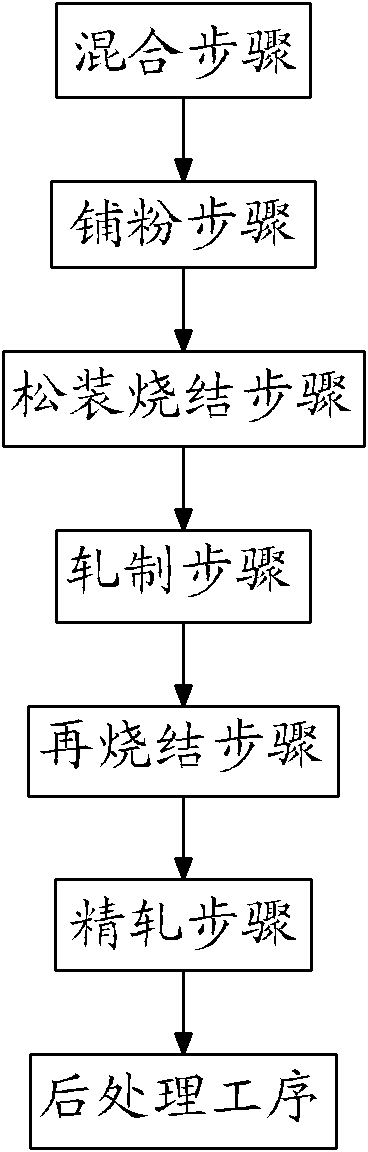

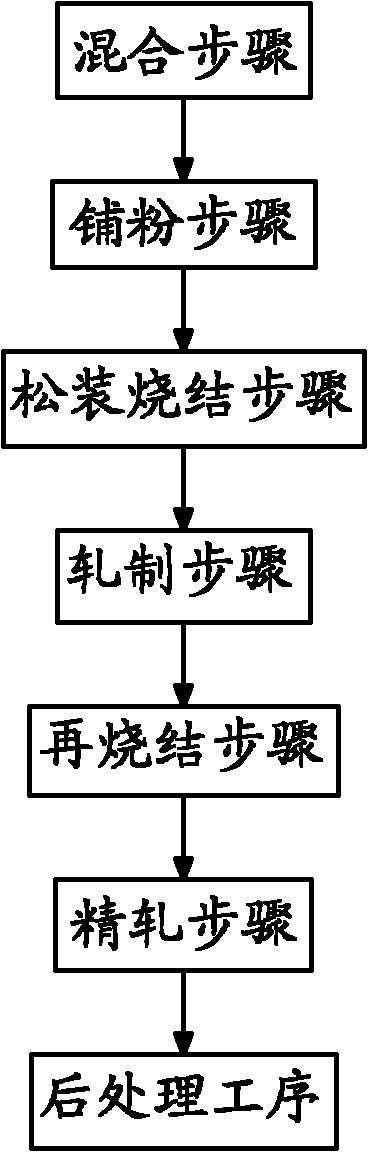

[0028] Please check figure 1 , the preparation method of the base material with copper-based dispersed bimetallic self-lubricating material, it comprises the steps:

[0029] Step 1, a mixing step, is used to put the copper-based alloy powder and the solid lubricant powder into a V-shaped mixer and mix for 1 to 5 hours;

[0030] Step 2, a powder spreading step, is used to spread the mixed powder evenly on the metal plate; the metal plate is a steel plate pretreated by copper plating;

[0031] Step 3, the loose-pack sintering step, is used to heat and sinter the powder-coated metal plate in a protective atmosphere, the sintering temperature is 750-860°C, and the sintering time is 0.5-2 hours;

[0032] Step 4, a rolling step, for rolling the metal plate in step 3 into a semi-finished product;

[0033] Step 5, the re-sintering step is used to heat and sinter the semi-finished product in a protective atmosphere, the sintering temperature is 750-860°C, and the sintering time is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com