Packaging locating device of microchannel lamination laser

A positioning device and micro-channel technology, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of stacked laser failure, affecting product quality, affecting assembly efficiency and accuracy, and reducing the possibility of damage to micro-channel units Sex, assembly process and inspection process are convenient, and the effect of improving assembly consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

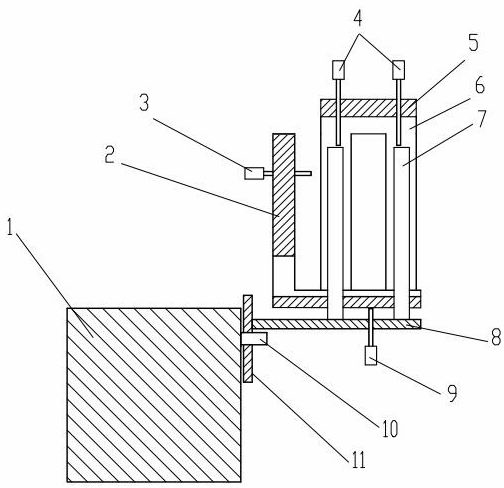

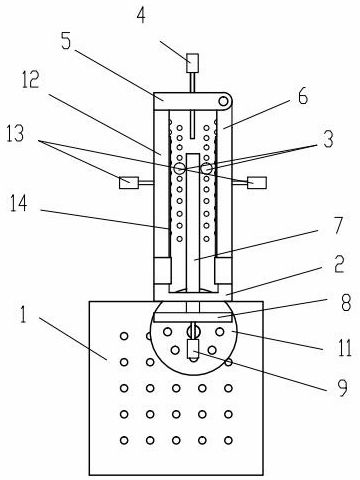

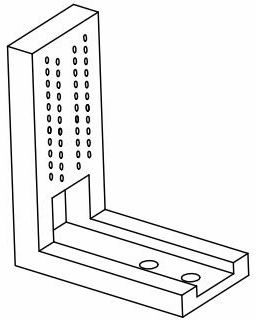

[0032] From attached Figure 1-7 It can be seen from the figure that the present invention specifically relates to a positioning device for microchannel laminated laser packaging, including a base and a positioning device for fixing the microchannel unit, and is characterized in that it also includes a compass 11 and an adjustment device, and the compass 11 is the center A perforated and rotatable circular structure, with round holes evenly distributed around the periphery, fixed on one side of the base by locking screws 10; the positioning device includes a bottom positioning piece 2, a top positioning piece 5, and a rear positioning plate 6 , the front positioning plate 12, the lifting rod 7 and the bottom surface 8 of the lifting device, the top positioning part 5 is hinged with the top of the rear positioning plate 6, and the rear positioning plate 6 and the front positioning plate 12 are fixed side by side on the bottom of the "L" shape On the bottom surface of the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com