Virtual error compensation system of numerical control machine

A technology of CNC machine tools and compensation systems, applied in general control systems, control/regulation systems, simulators, etc., can solve problems such as the inability to automatically adapt to changes in machining conditions, and the inability to achieve comprehensive compensation for CNC machine tool errors, and improve machining accuracy. , easy to operate, and ensure the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

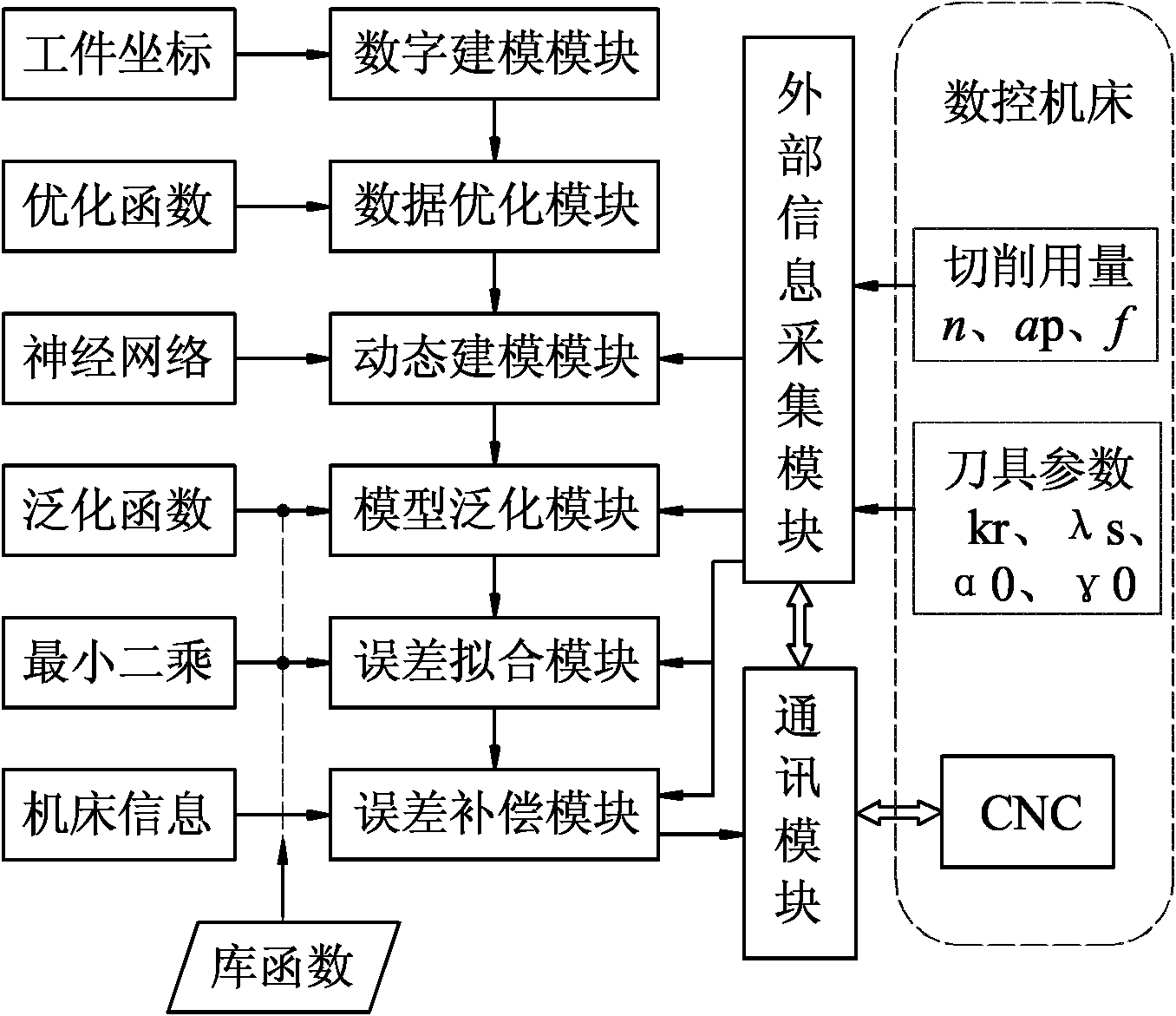

[0018] like figure 1 As shown, this embodiment includes: an external data acquisition module, a digital modeling module, a data optimization module, a dynamic modeling module, a model generalization module, an error fitting compensation module and a communication module, wherein: the external data acquisition module passes the environmental information The acquisition unit collects external information and outputs it to the dynamic modeling module, model generalization module, and error fitting compensation module through the data conversion program and the data output channel; the digital modeling module generates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com