Six-axis robot self-adaptive deburring machining mechanism and control method thereof

A six-axis robot and processing mechanism technology, which is applied in the control of workpiece feed movement, metal processing equipment, manipulators, etc., can solve the problems of low deburring processing efficiency, inability to feed the tool in time, and processing posture deviation. , to achieve the effect of avoiding repeated tool setting, maximizing utilization and reducing replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The six-axis robot adaptive deburring mechanism and its control method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

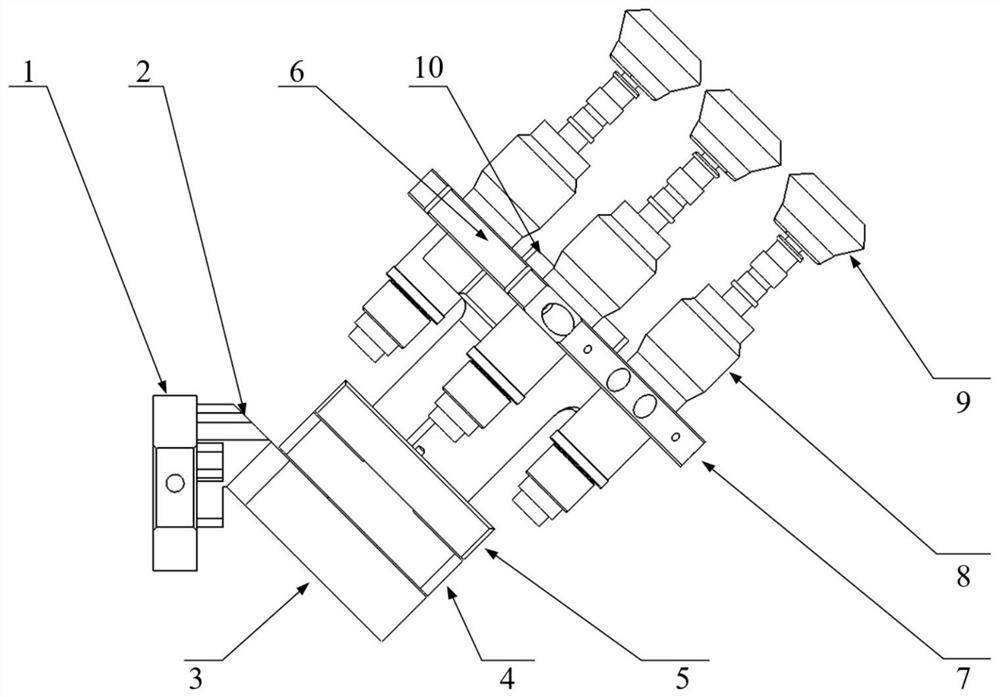

[0030] Such as Figures 1 to 4 As shown, a six-axis robot adaptive deburring processing mechanism includes a force sensor base 3, a three-dimensional force sensor 4, a sensor lintel 5 and a base plate 6, and a positioning standard rod is vertically fixed in the middle of the front side of the base plate 6 10 (when installing the brushes, provide a reference for the positioning of the four brushes to ensure that they are on the same working plane), a number of brush motor units 8 are evenly fixed on the base plate 6, and the front side of the brush motor units 8 passes through the joint Shaft device is connected with bowl type stainless steel wire brush 9. The three-dimensional force sensor 4 is fixed on the force sensor base 3 , the sensor bridge 5 is in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com