Liquid crystal display substrate and manufacturing method thereof

A technology of liquid crystal display and manufacturing method, which is applied in the field of liquid crystal display, and can solve problems such as reducing aperture ratio, reducing pixel unit area, unevenness, etc., and achieves the effect of reducing restrictions and reducing height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

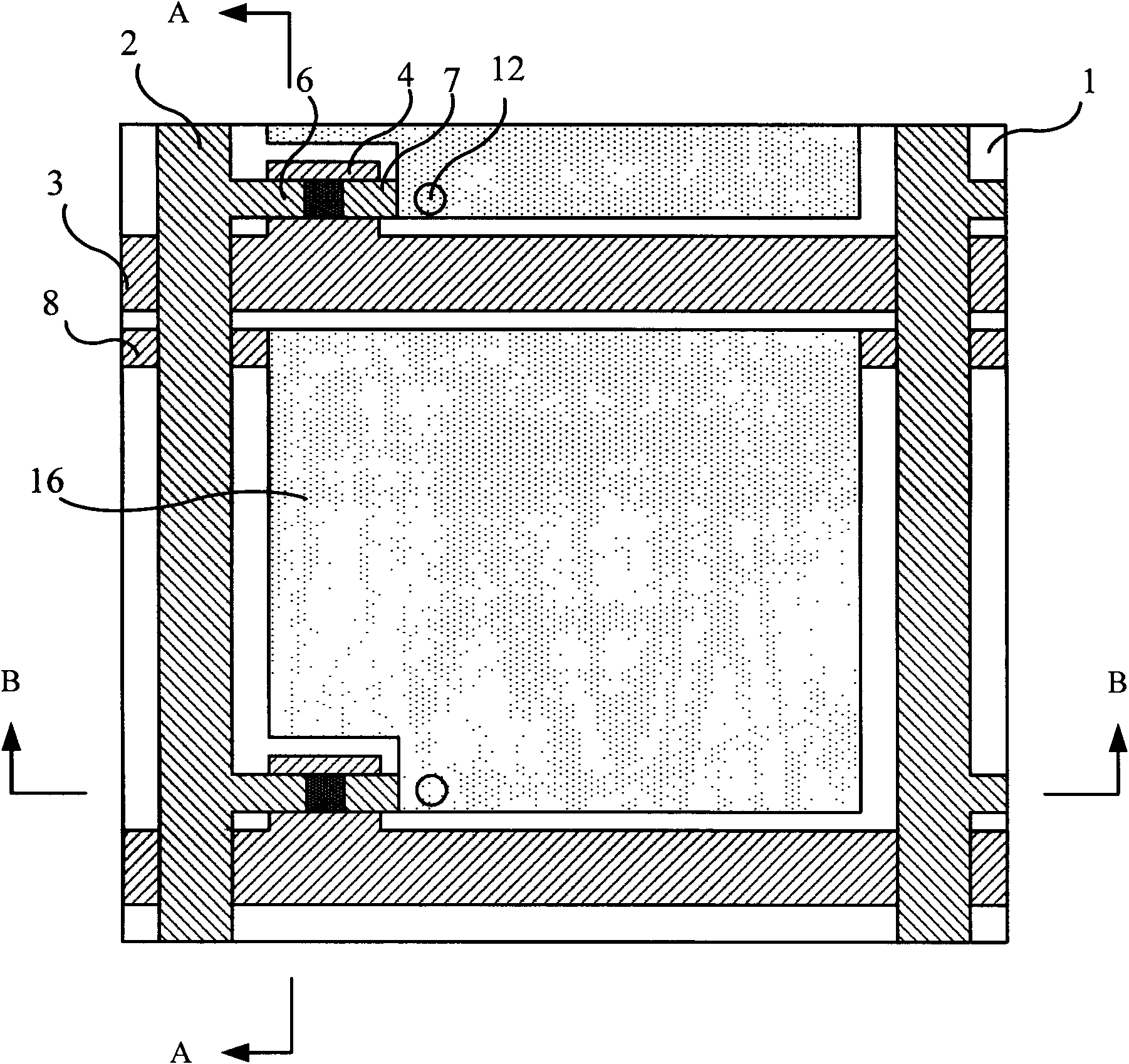

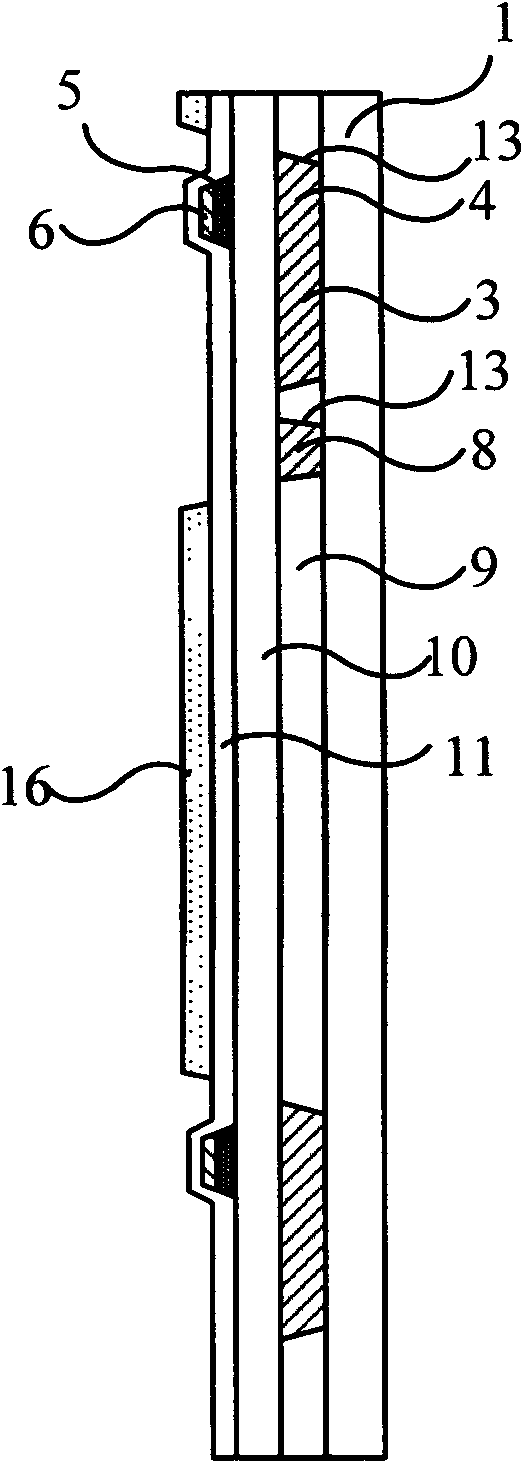

[0029] figure 1 It is a schematic diagram of a partial top view structure of a liquid crystal display substrate provided in Embodiment 1 of the present invention, figure 2 for figure 1 The schematic diagram of the cross-sectional structure in the A-A direction, image 3 for figure 1 A schematic diagram of the cross-sectional structure along the B-B direction in . The liquid crystal display substrate of this embodiment may specifically be an array substrate, including a base substrate 1 on which data lines 2 and gate scanning lines 3 crossing vertically and vertically are formed, surrounding a plurality of array substrates forming a matrix. pixel unit. Each pixel unit is provided with a TFT switch, and the TFT switch includes a gate electrode 4 , an active layer 5 , a source electrode 6 and a drain electrode 7 . The gate electrode 4 is connected to the gate scanning line 3, and is generally formed at the same time as the gate scanning line 3; the source electrode 6 is con...

Embodiment 2

[0038] Figure 4 The schematic diagram of the partial cross-sectional structure of the liquid crystal display substrate provided by Embodiment 2 of the present invention is different from Embodiment 1 in that the groove formed on the substrate insulating layer 9 also includes a second groove 14 formed on the gate insulating layer 10 The data line 2 , the source electrode 6 and the drain electrode 7 are formed in the second trench 14 . The top view structure of the liquid crystal display substrate in this embodiment can be found in figure 1 as shown, Figure 4 can be along figure 1 The schematic diagram of cutting the liquid crystal display substrate of this embodiment by the B-B line in the present embodiment, Figure 5 It is a partial top view structural schematic diagram of the substrate insulating layer 9 in the liquid crystal display substrate provided by Embodiment 2 of the present invention. The first groove 13 and the second groove 14 may be through grooves with equ...

Embodiment 3

[0043] Figure 6 It is a schematic diagram of a partial cross-sectional structure of a liquid crystal display substrate provided in Embodiment 3 of the present invention, Figure 7 It is a schematic diagram of a partial top view structure of the gate insulating layer 10 in the liquid crystal display substrate provided by Embodiment 3 of the present invention. In this embodiment, the insulating layer between the data line 2, the source electrode 6 and the drain electrode 7 and the gate scanning line 3, the gate electrode 4 and the common electrode line 8 is a gate insulating layer 10, and the insulating layer formed on the gate insulating layer 10 The trenches include a third trench 15 in which at least one or more of the data line 2 , the source electrode 6 and the drain electrode 7 are formed. The depth of the third trench 15 is smaller than the thickness of the gate insulating layer 10 , so as to avoid contact and conduction with the gate scanning line 3 under the gate insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com