A veneer connection structure

A technology for connecting structures and decorative panels, applied in the field of building decoration materials, can solve the problems of difficulty in rapid heat transfer, complex manufacturing processes, long heat conduction paths, etc., and achieve the effects of short heat conduction paths, good thermal stability, and high heat conduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

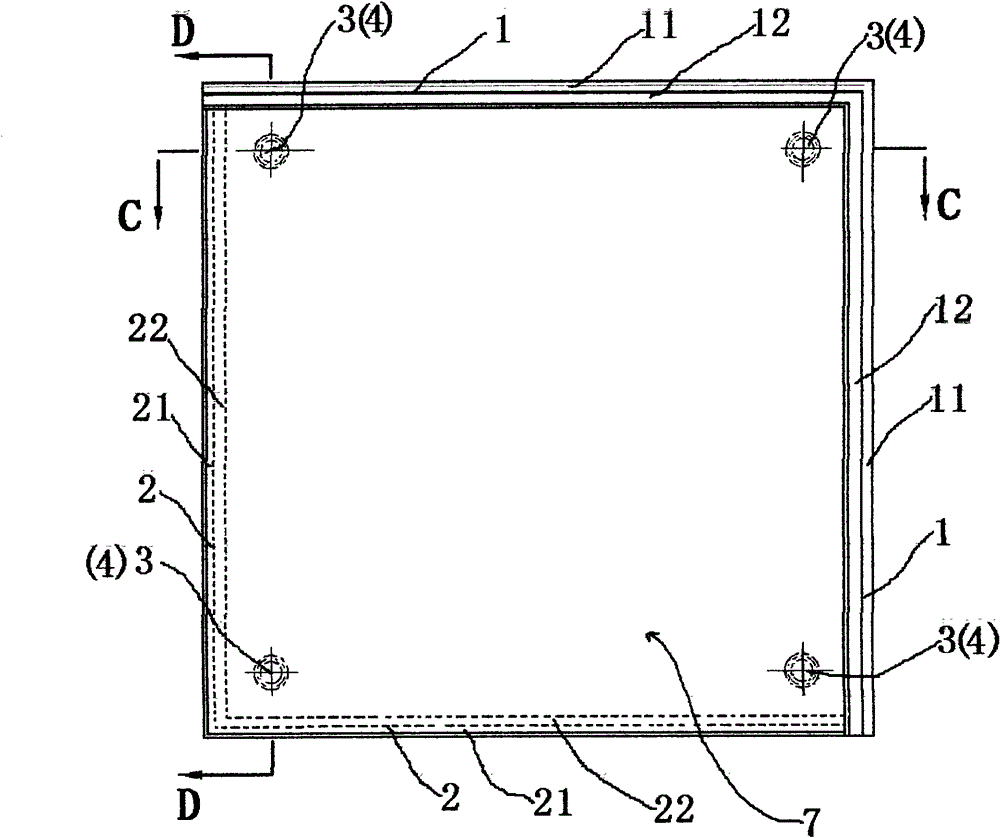

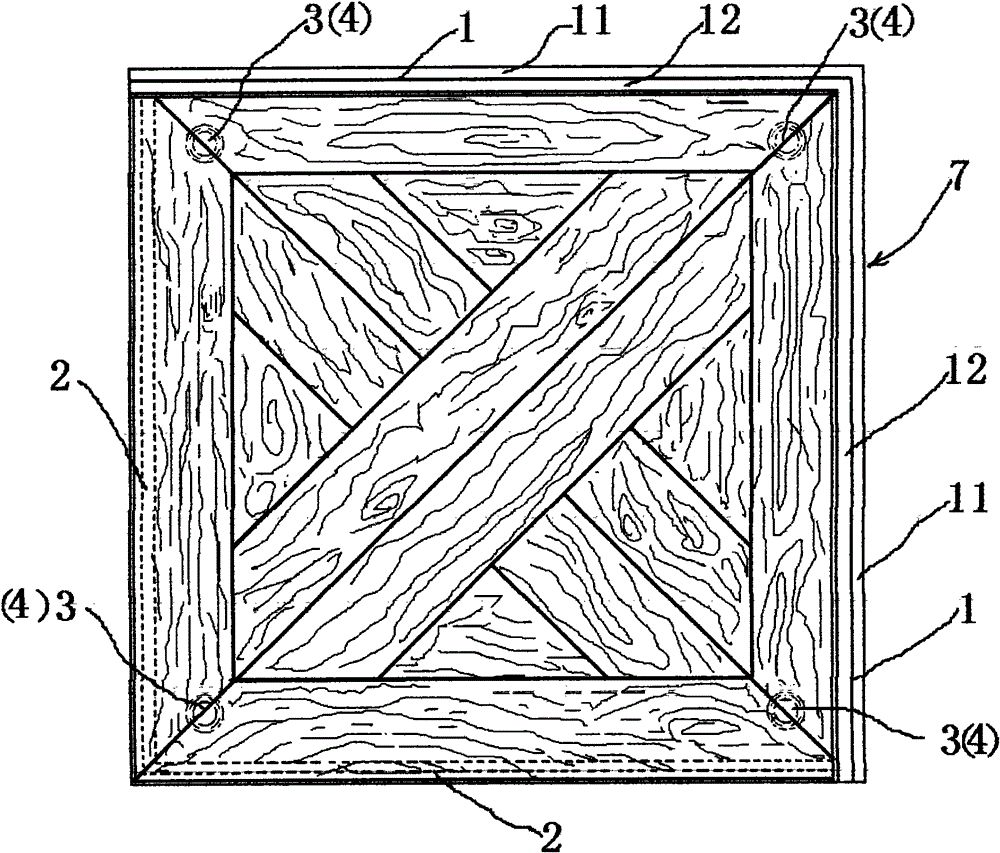

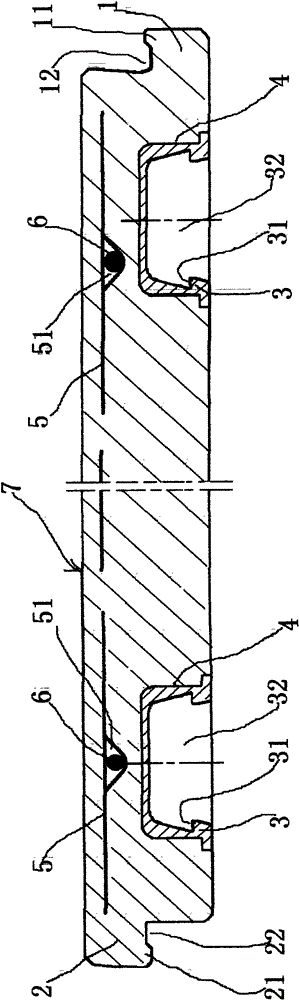

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 or Figure 5As shown, a veneer 7 includes a veneer 7 body, the veneer 7 body has a square plate-like structure, and the veneer 7 is composed of four sides connected end to end, wherein two adjacent sides are similarly provided with self-decoration panels 7. The first tongue-and-groove structure 1 extending from the lower bottom. The length of the first tongue-and-groove structure 1 is equal to the lower edge of the veneer 7. The first tongue-and-groove structure 1 includes a first tenon body 11 and a first groove body 12 , the other adjacent two sides are also provided with a second tongue-and-groove structure 2 extending from the upper surface of the veneer 7, the length of the second mortise structure 2 is equal to the upper edge of the veneer 7, and the second The tongue and groove structure 2 includes a second tenon body 21 and a second groove body 22. The first tenon body 11 and the second groove body...

Embodiment 2

[0029] Embodiment 2: as Figure 6 , Figure 7 , Figure 8 , Figure 9 or Figure 10 As shown, a connection structure of veneer panels 7 includes adjacent first veneer panels 71, second veneer panels 72, third veneer panels 73, fourth veneer panels 74, and independent coupling elements 8 that jointly connect them. It is designed so that adjacent veneer panels 7 are connected not only through the engagement of the first tongue-and-groove structure 1 and the second mortise-and-groove structure 2 to form a snap connection, but also through an independent coupling element 8 to realize that the adjacent first veneer panel 71 and the second veneer panel 71 are connected to each other. Coupling of the panel 72, the third veneer 73 and the fourth veneer 74, wherein the first tongue-and-groove structure 1 in the first veneer 71 and the second tongue-and-groove structure 2 in the second veneer 72 engage with each other Form a snap connection, the second tongue and groove structure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com