Dual-purpose lubricating agent for rust prevention and washing and preparation method thereof

The technology of a lubricant and an anti-rust agent is applied in the field of anti-rust washing dual-purpose lubricant and its preparation, which can solve the problems of redness, swelling and itching of the user's skin, waste of resources, unsafety and the like, and achieves good cleaning performance and meets the requirements of anti-rust. Demand, the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

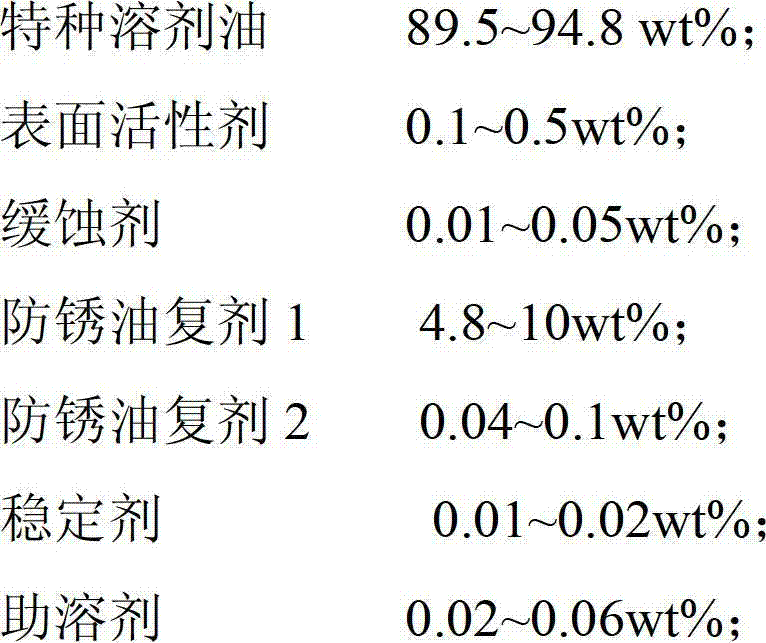

Embodiment 1

[0029] Use special solvent oil as base oil. In the production process, first add 91.56kg of special solvent oil into the reaction kettle, heat it to about 35-45°C, and stir; add 8kg of antirust agent compound 1, 0.06kg of antirust agent compound agent 2 in turn, and continue stirring 25-35 minutes; add 0.03kg of corrosion inhibitor, 0.01kg of stabilizer and 0.04kg of co-solvent in sequence, and continue to stir for 25-35 minutes; finally add 0.3kg of surfactant and continue to stir for 25-35 minutes to obtain dual-purpose lubrication for rust prevention and washing agent.

Embodiment 2

[0031] Use special solvent oil as base oil. In the production process, first add 94.50kg of special solvent oil into the reaction kettle, heat it to about 35-45°C, and stir; add 5kg of antirust agent compound 1, 0.1kg of antirust agent compound agent 2 in turn, and continue stirring 25-35 minutes; add 0.05kg of corrosion inhibitor, 0.02kg of stabilizer and 0.06kg of co-solvent in sequence, and continue to stir for 25-35 minutes; finally add 0.27kg of surfactant and continue to stir for 25-35 minutes to obtain dual-purpose lubrication for rust prevention and washing agent.

Embodiment 3

[0033] Use special solvent oil as base oil. In the production process, first add 89.5kg of special solvent oil into the reaction kettle, heat it to about 35-45°C, and stir; add 10kg of antirust agent compound 1, 0.08kg of antirust agent compound agent 2 in turn, and continue stirring 25-35 minutes; add 0.02kg of corrosion inhibitor, 0.01kg of stabilizer and 0.02kg of co-solvent in sequence, and continue to stir for 25-35 minutes; finally add 0.37kg of surfactant and continue to stir for 25-35 minutes to obtain dual-purpose lubrication for rust prevention and washing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com