Equipment system for industrially producing Grignard reagent by using gaseous halogenated hydrocarbon

A technology of Grignard reagent and halogenated hydrocarbon, which is applied in the industrial application field of Grignard reaction, can solve the problems of increasing investment in separation and recovery equipment, and achieve the effect of realizing clean production, avoiding reaction quenching, and solving unsafe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following preferred embodiments merely illustrate the present invention and are not meant to limit the present invention.

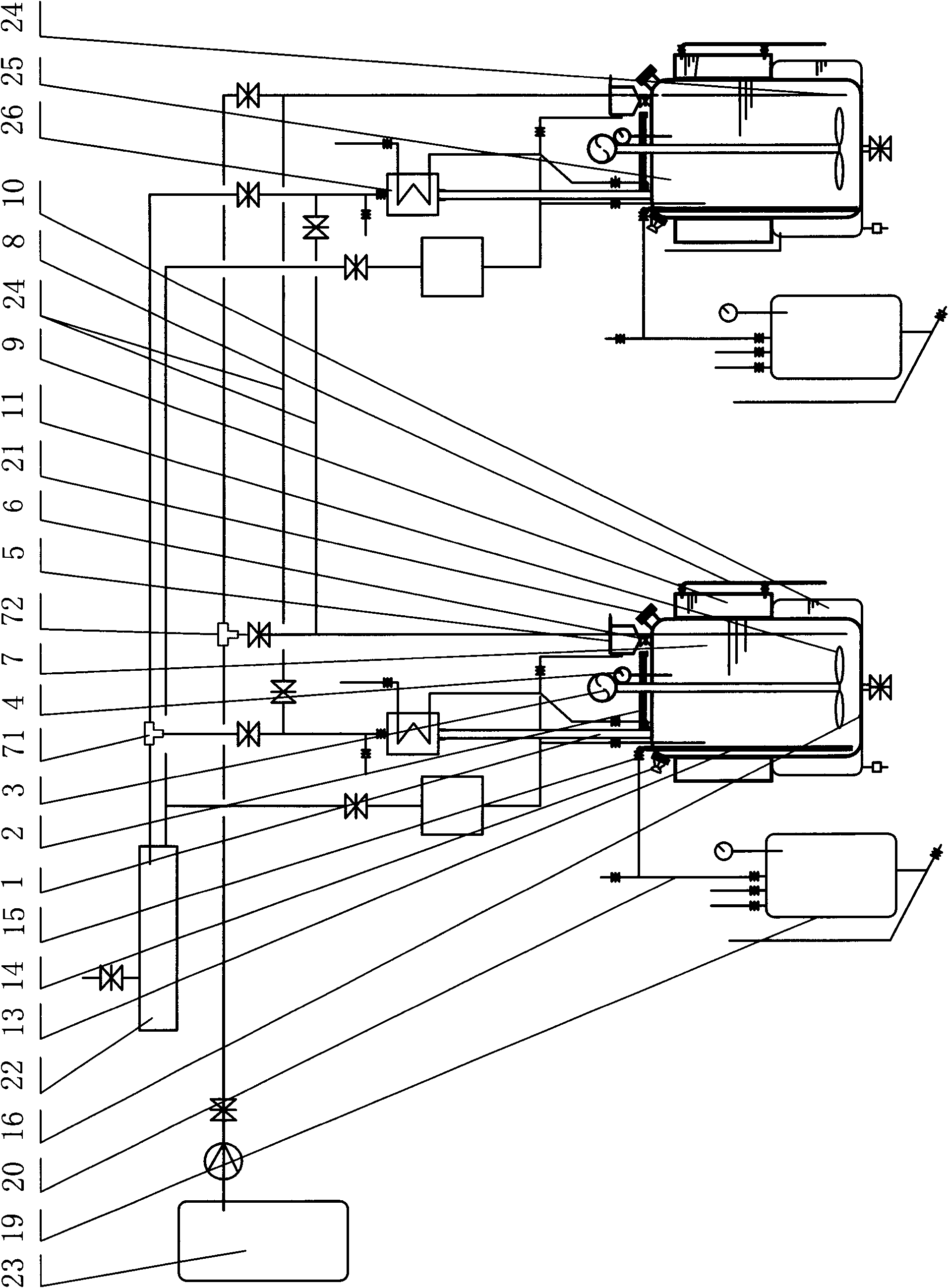

[0022] figure 1 It is a schematic diagram of the structure of the present invention. The equipment system includes a raw material feeding system, two reactors 7, 25, and the two reactors 7, 25 are designed in series, wherein the raw material feeding system includes tetrahydrofuran or ether storage and absorption tank 22, gas halogenated hydrocarbon pressure storage tank 23 and magnesium feeding chamber 5, tetrahydrofuran or ether storage and absorption tank 22 are respectively connected with two reactors 7, 71 by three-way valve 71, and gas halogenated hydrocarbon pressure storage tank 23 is respectively connected with two by three-way valve 72. The reaction kettles 7 and 71 are connected, and each reaction kettle 7 is equipped with a magnesium feeding chamber 5. Taking the reaction kettle 7 as an example, the magnesium feeding chamber 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com