Polycrystalline silicon producing device and process

A production device and polysilicon technology, applied in the direction of silicon, halosilane, halide silicon compounds, etc., can solve the problems of increasing the consumption of raw material silicon powder and liquid chlorine, affecting the quality of polysilicon, and difficult to purify, so as to save raw materials and reduce Safety risk, high conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

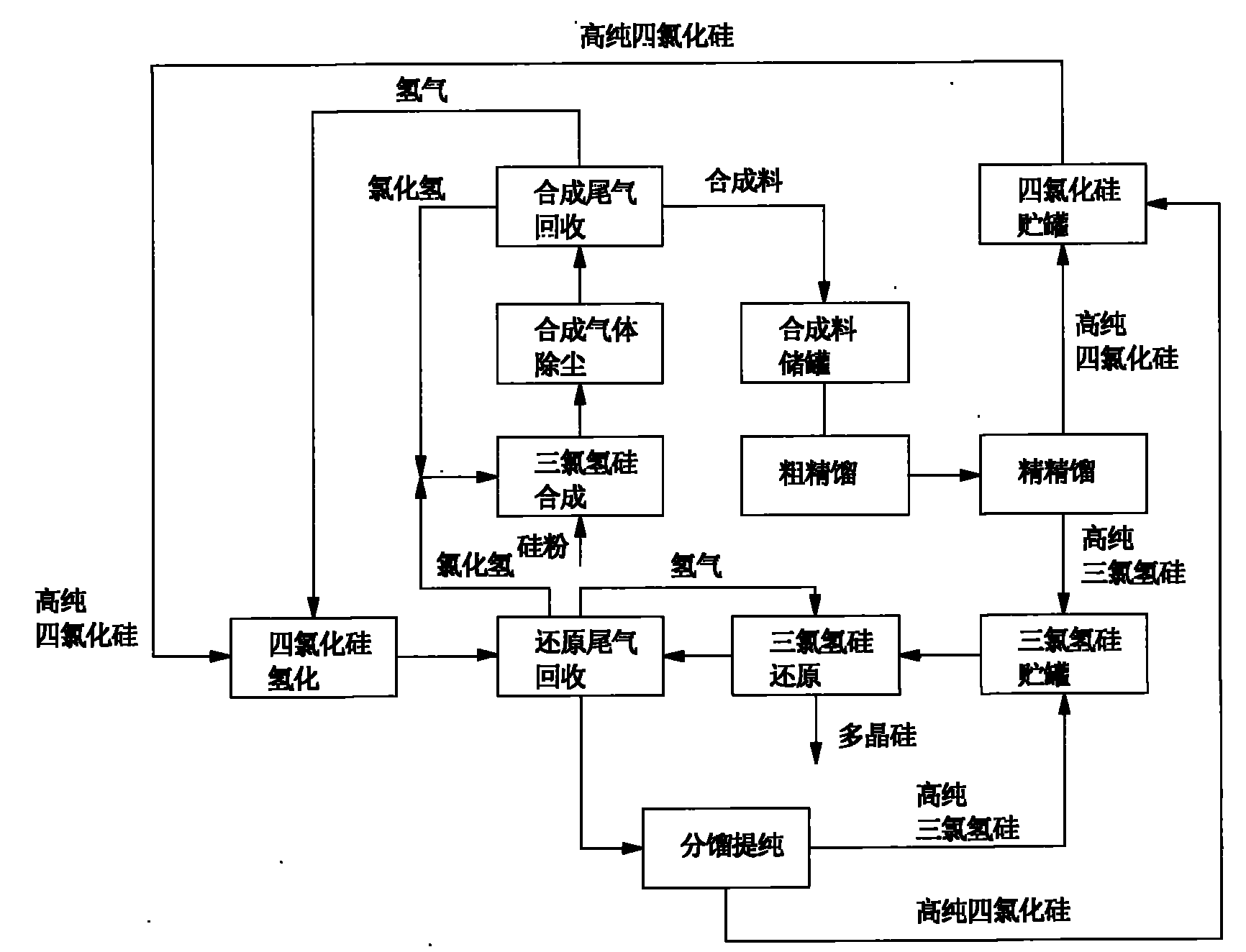

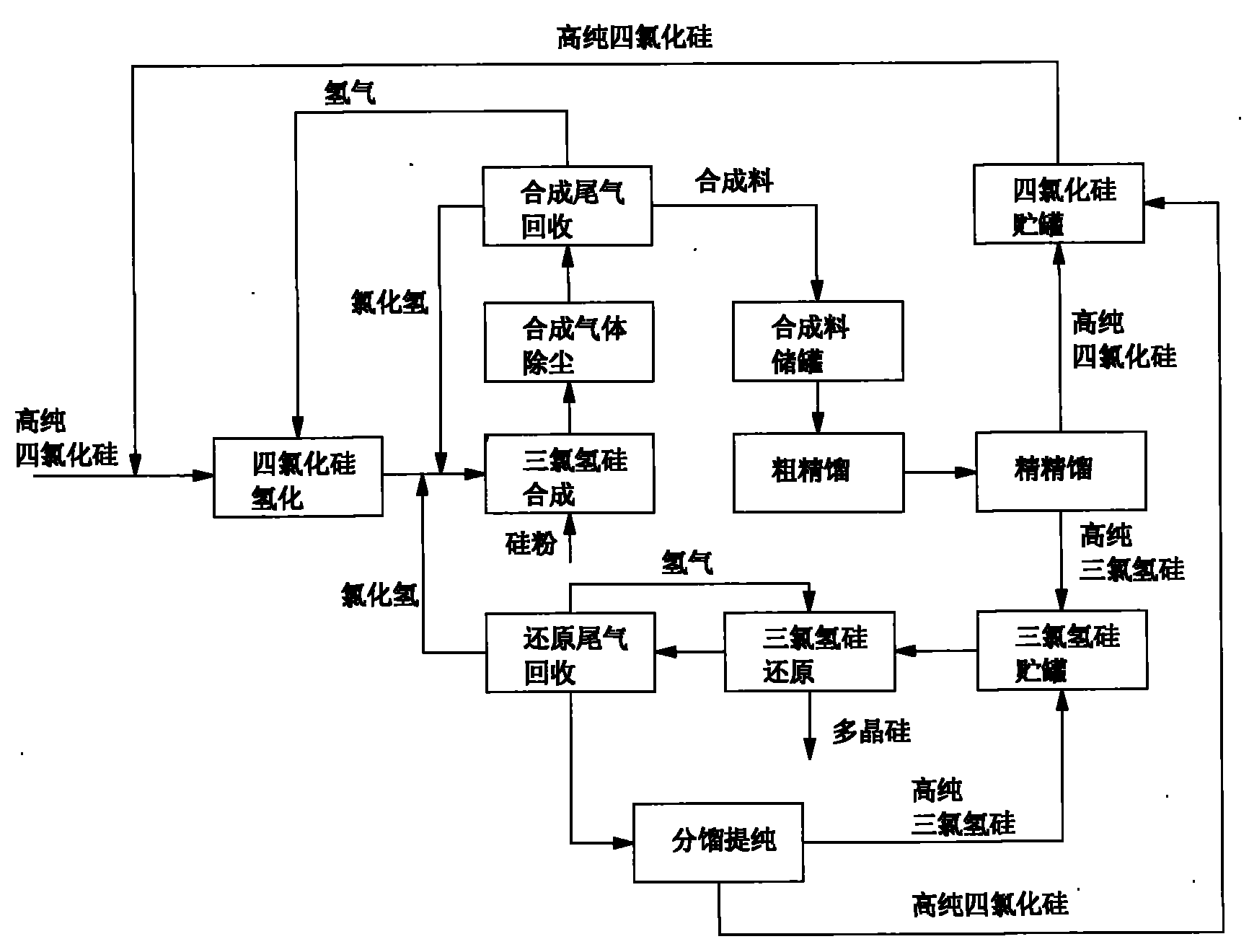

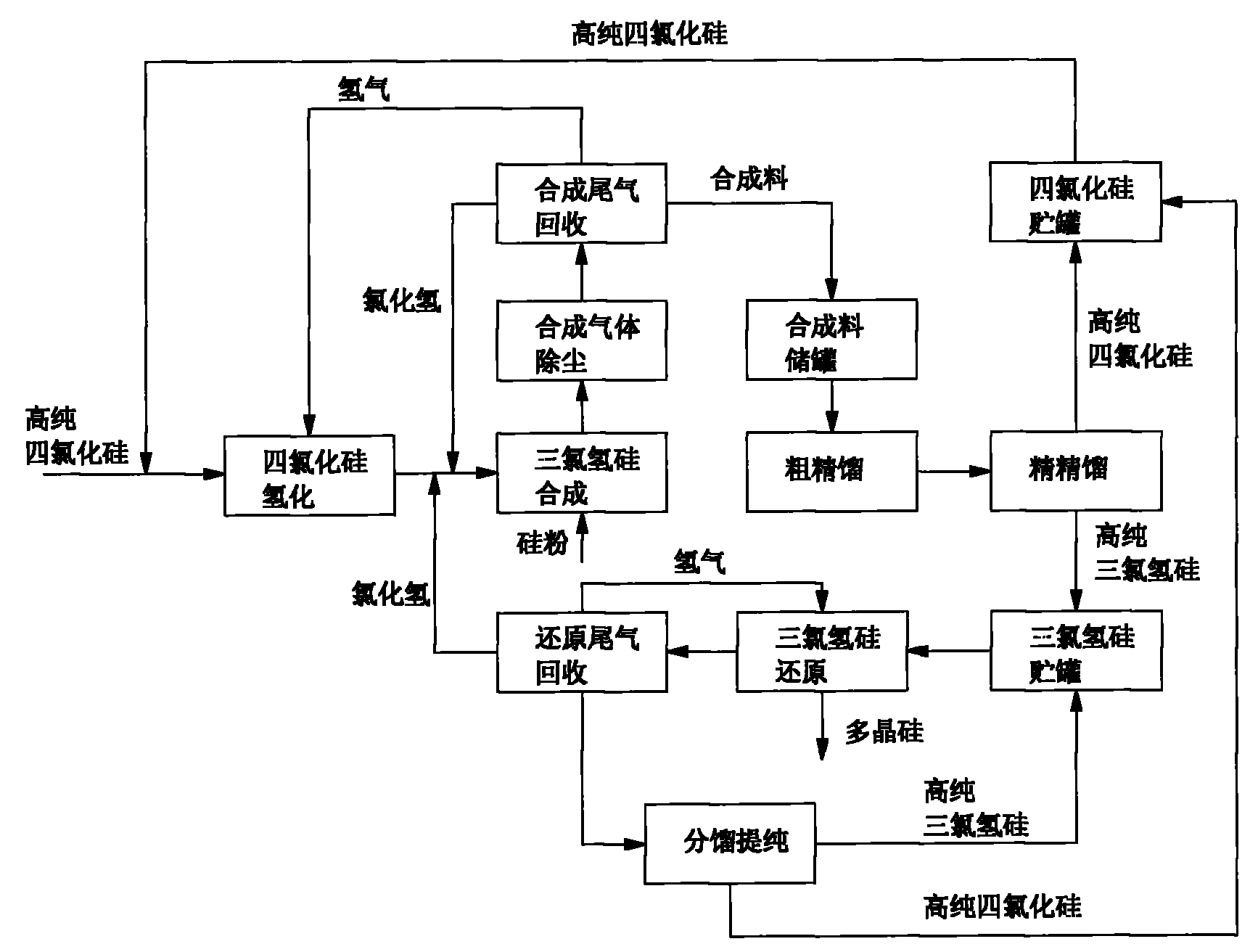

[0027] The polysilicon production device provided by the present invention has transformed the traditional polysilicon production device, and the tail gas outlet of the silicon tetrachloride hydrogenation furnace is connected with the feed port of the trichlorosilicon synthesis furnace, so that the tail gas produced by the hydrogenation of silicon tetrachloride is directly Participate in the synthesis of trichlorosilane.

[0028] The tail gas of the trichlorosilane synthesis furnace enters the synthesis tail gas recovery device after passing through the dust removal device, where the tail gas is recovered and separated, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com