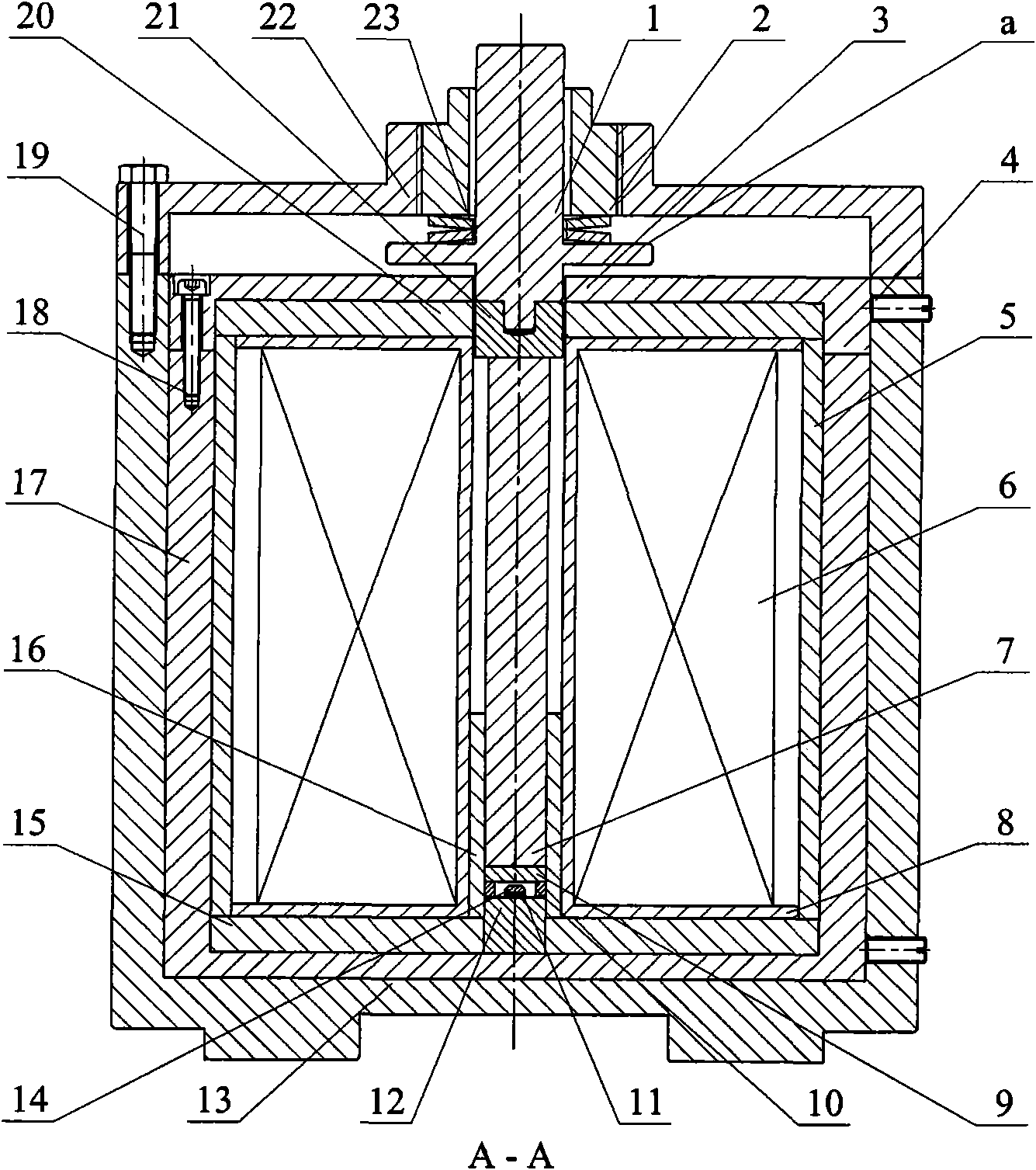

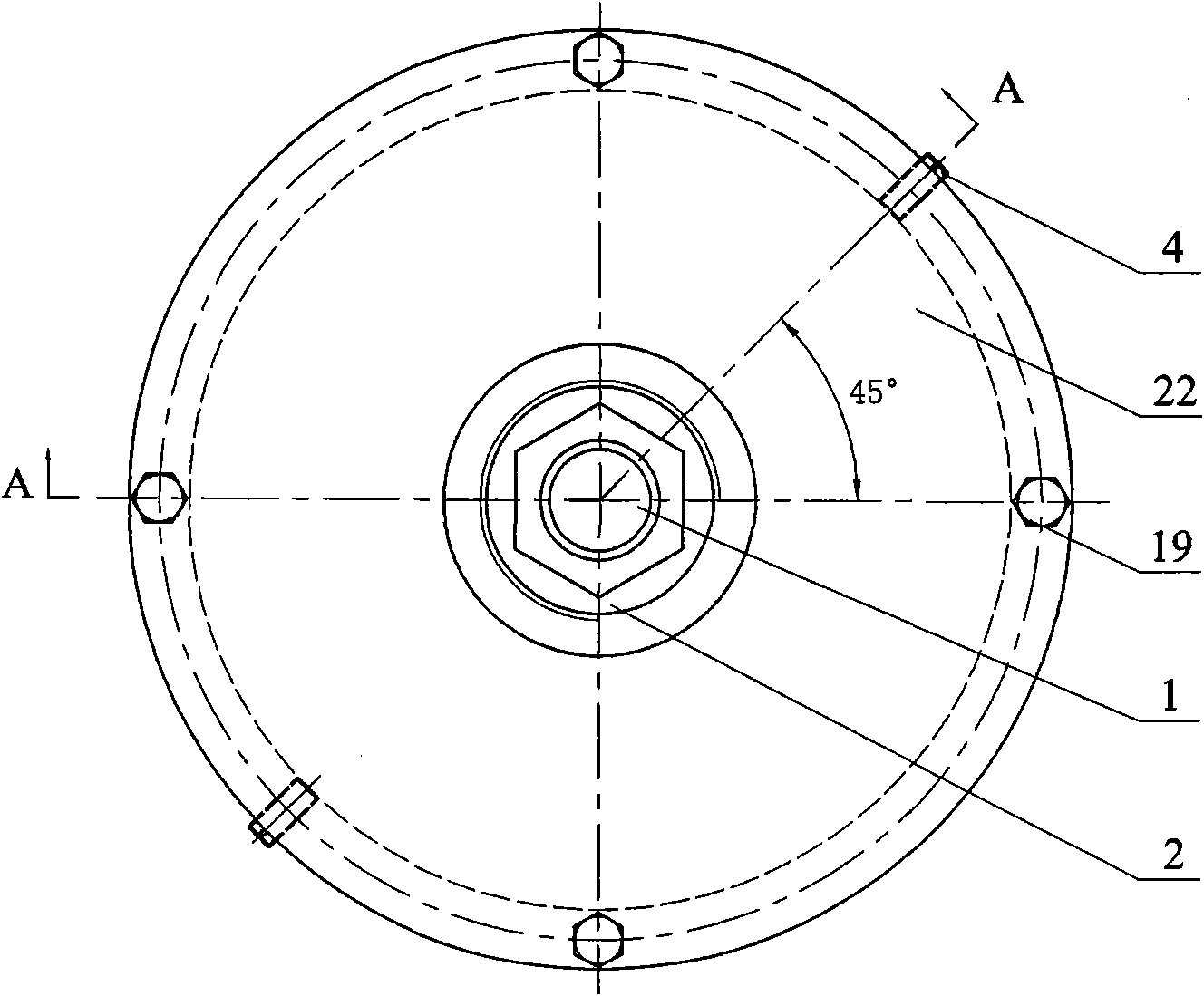

Giant magnetostrictive actuator with permanet torque output and control method thereof

A technology of giant magnetostrictive and giant magnetostrictive rods, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

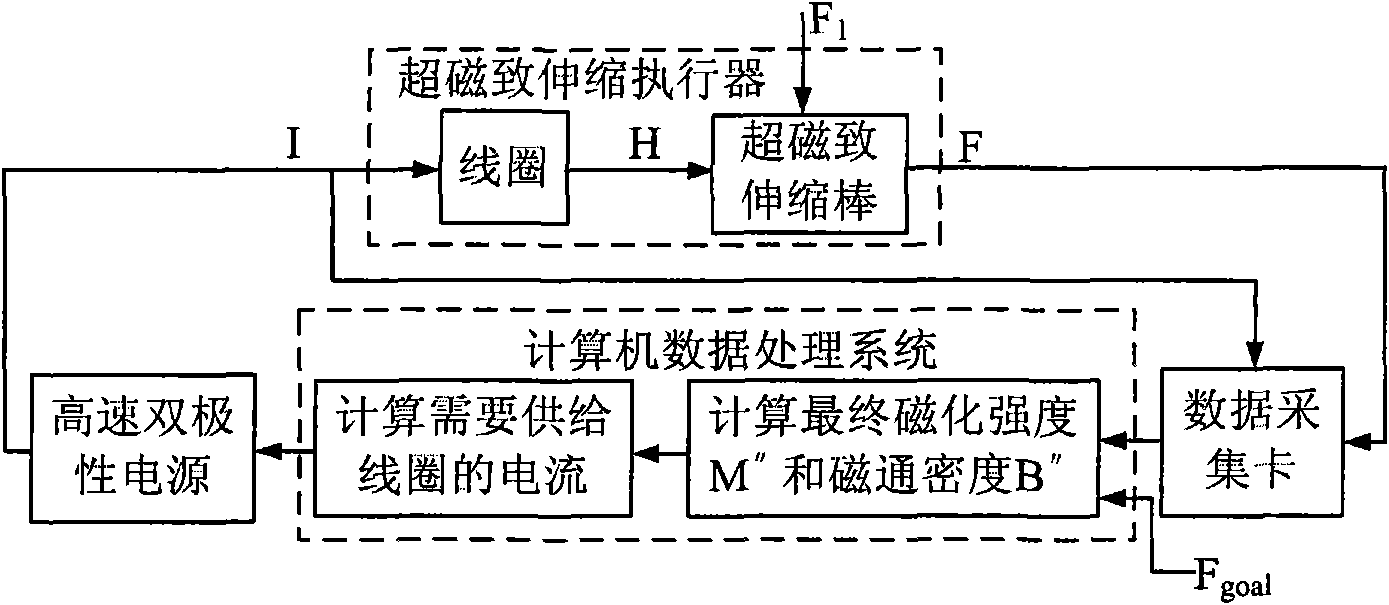

Embodiment 1

[0041] Embodiment 1 - The external force is a static force: in this embodiment, the size of the giant magnetostrictive rod is Φ12×100mm, the height and the number of turns of the coil 8 are respectively 0.114m and 1800 turns, and the outer diameter of the enameled wire strip is 1.43mm. The shape spring 27 is an A series disc spring 35.5, and the Hall sensor 16 is a linear Hall sensor A1302EUA produced by Allegro Company of the United States, with a sensitivity of 1.3mv / G. Figure 5 is a schematic diagram of the experimental system, in which the main parameters of the main components are as follows: BP4610 high-speed bipolar power supply is selected, and the minimum adjustable current is ±0.001A. The LSM-3000 load cell is selected, the maximum measuring range is 3000N, and the minimum measuring force is 0.1N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com