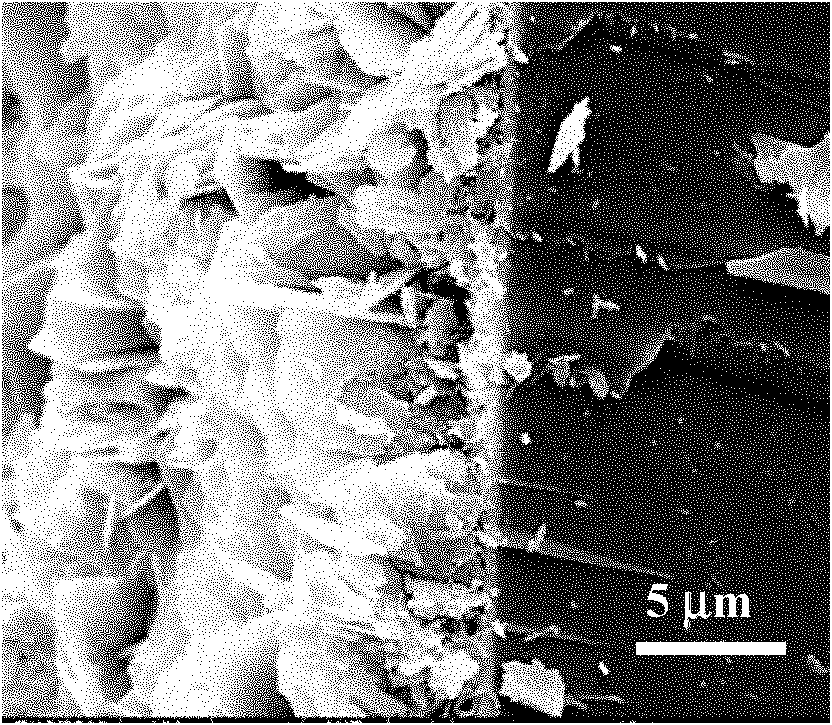

Method for preparing sensitized ZnO nano-plate photo-anode of PbS quantum dot

A quantum dot sensitization and nanosheet technology, which is applied in the direction of photosensitive equipment, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of uneven distribution of quantum dots, complex preparation process, limited use of light energy, etc. The method is simple, the deposition is uniform, and the effect of improving the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] A kind of specific embodiment of the present invention is: a kind of preparation method of PbS quantum dot sensitized ZnO nano sheet photoanode, and its concrete method is:

[0027] The fluorine-doped SnO2 conductive glass is washed with detergent, dilute hydrochloric acid, acetone, and deionized water in sequence before being deposited, dried and then subjected to the following operations.

[0028] a. Preparation of ZnO nanosheets by electrodeposition

[0029] With platinum as auxiliary electrode, saturated calomel electrode as reference electrode, fluorine-doped SnO 2 The conductive glass is the working electrode, and the electrolyte is Zn(NO 3 ) 2 and KCl mixture, where Zn(NO 3 ) 2 The concentration of KCl is 0.05M, and the concentration of KCl is 0.06M; the electrolytic cell is placed in a constant temperature tank at 70°C, the constant voltage is -1.1V, and the electrodeposition is carried out for 1.5 hours under stirring conditions. The sediment is taken out, ...

Embodiment 2

[0038] The approach in this example is:

[0039] a. Preparation of ZnO nanosheets by electrodeposition

[0040] With platinum as auxiliary electrode, saturated calomel electrode as reference electrode, fluorine-doped SnO 2 The conductive glass is the working electrode, and the electrolyte is Zn(NO 3 ) 2 and KCl mixture, where Zn(NO 3 ) 2 The concentration of KCl is 0.04M, and the concentration of KCl is 0.07M; the electrolytic cell is placed in a constant temperature tank at 60°C, the constant voltage is -1.0V, and the electrodeposition is carried out for 1.8 hours under stirring conditions. The sediment is taken out, rinsed with deionized water, and dried Dry, normalize at 400°C for 50 minutes to obtain ZnO nanosheets;

[0041] b. Preparation of ZnO / PbS composite film in successive chemical baths

[0042] Soak the ZnO nanosheets prepared in step a in 0.15M Pb(NO 3 ) 2 solution, deionized water, 0.15M Na 2 S solution and deionized water each for 40s, 20s, 10s, 40s are...

Embodiment 3

[0044] The approach in this example is:

[0045] a. Preparation of ZnO nanosheets by electrodeposition

[0046] With platinum as auxiliary electrode, saturated calomel electrode as reference electrode, fluorine-doped SnO 2 The conductive glass is the working electrode, and the electrolyte is Zn(NO 3 ) 2 and KCl mixture, where Zn(NO 3 ) 2 The concentration of KCl is 0.06M, and the concentration of KCl is 0.06M; the electrolytic cell is placed in a constant temperature tank at 80°C, the constant voltage is -1.2V, and the electrodeposition is carried out for 2 hours under stirring conditions, and the sediment is taken out, rinsed with deionized water, dried Dry, normalize at 430°C for 40 minutes to obtain ZnO nanosheets;

[0047] b. Preparation of ZnO / PbS composite film in successive chemical baths

[0048] Soak the ZnO nanosheets prepared in step a in 0.12M Pb(NO 3 ) 2 solution, deionized water, 0.12M Na 2 S solution and deionized water each for 40s, 20s, 10s, and 40s a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com