Device and method for detecting dynamic properties of two-dimensional directional mirror

A dynamic performance and detection device technology, applied in the direction of measuring devices, testing optical properties, measuring angles, etc., can solve problems such as limited measurement speed, large tracking error, and single motion form of the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

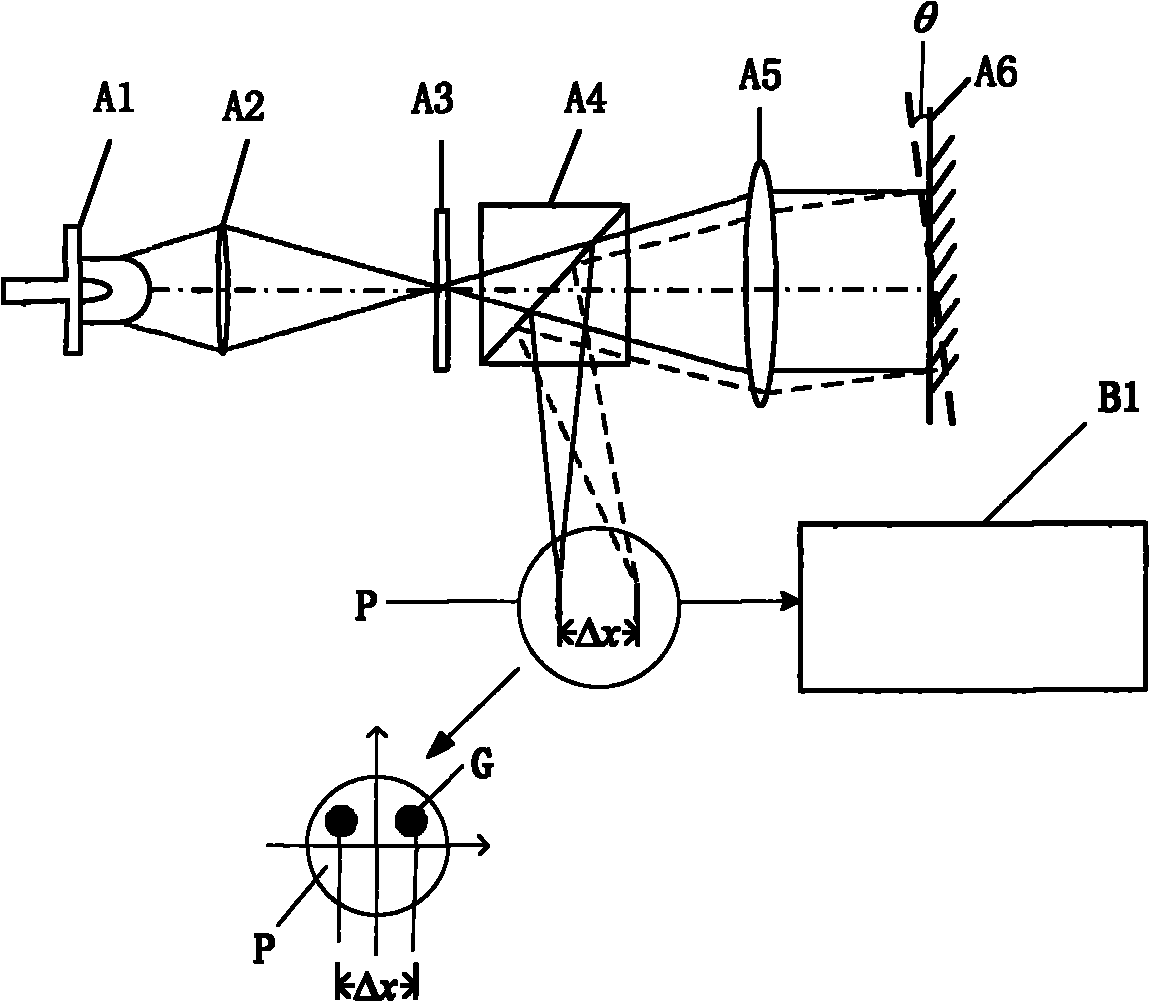

[0062] see first figure 1 , figure 1 Shown is a schematic diagram of the working principle of the dynamic photoelectric autocollimator. Along the direction of the horizontal optical axis, the beam emitted by the laser A1 is converged by the condenser lens A2 and then illuminates the reticle A3, where A3 is located at the focal plane of the collimating objective lens A5, and the beam passing through the reticle A3 passes through the beam splitting prism and the collimating objective lens in turn Finally, a parallel beam output is formed, where the beam-splitting surface of the beam-splitting prism forms an angle of 45° with the horizontal optical axis. The output parallel light beams are reflected by the mirror A6 under test and are imaged on the photodetection device P af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com