Waste paper on-line automatic measuring system

An automatic measurement and waste paper technology, applied in the field of measurement system, can solve the problems of time-consuming and laborious operation, inconvenient, etc., and achieve the effect of accurate measurement, stable quality, convenient and timely data accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

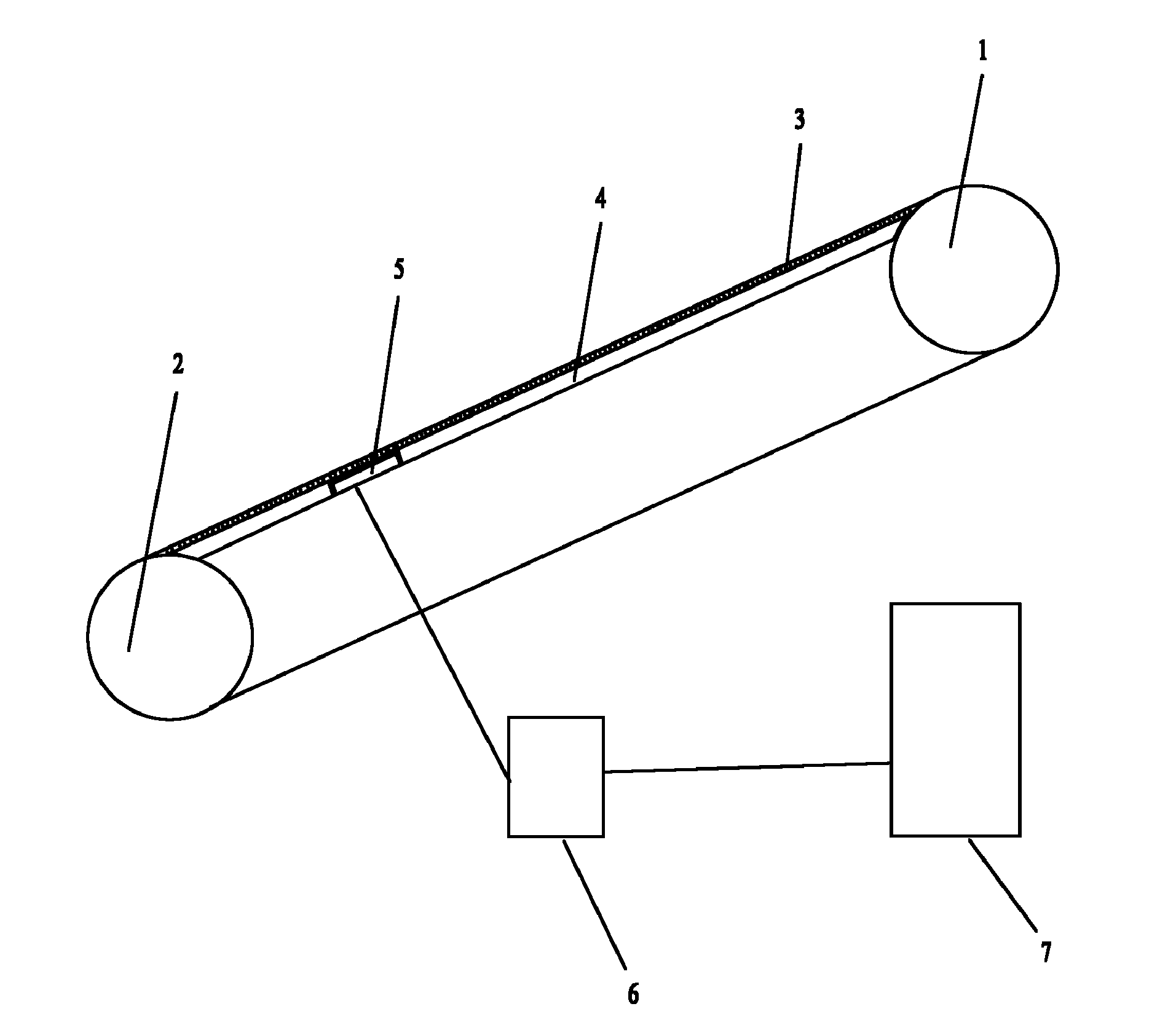

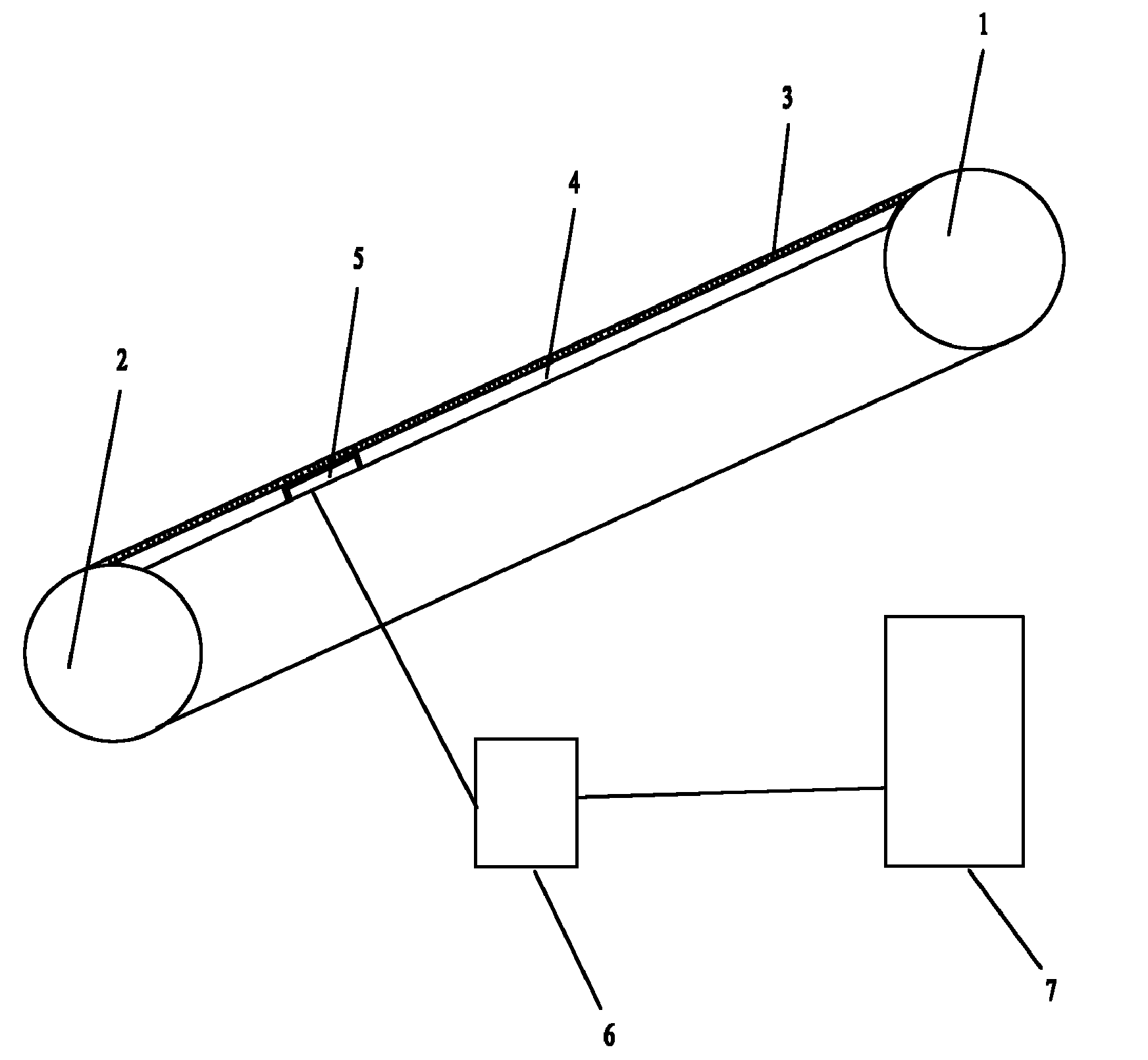

[0026] See figure 1 , an online automatic metering system for waste paper, including a driving ratchet 1, a driven ratchet 2 and a chain plate 3 sleeved on the driving ratchet 1 and the driven ratchet 2. Driven by the ratchet 2, the chain plate 3 is provided with a chain plate support 4, the chain plate support 4 is located above the driving ratchet 1 and the driven ratchet 2, and the chain plate support 4 is fixed with a chain plate scale 5. The chain plate scale 5 is connected with a data processing system 6 , and the data processing system 6 is connected with a central control system 7 . The whole process of the present invention is carried out automatically without additional labor, sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com