Refrigeration agent compressor and refrigeration cycling device

A refrigeration cycle and refrigerant technology, which is applied to parts, mechanical equipment, machines/engines, etc. of elastic fluid pumping devices, can solve the problems of higher precision, increased product cost, and time-consuming fine polishing, etc., to prevent Notch, the effect of improving the initial running-in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

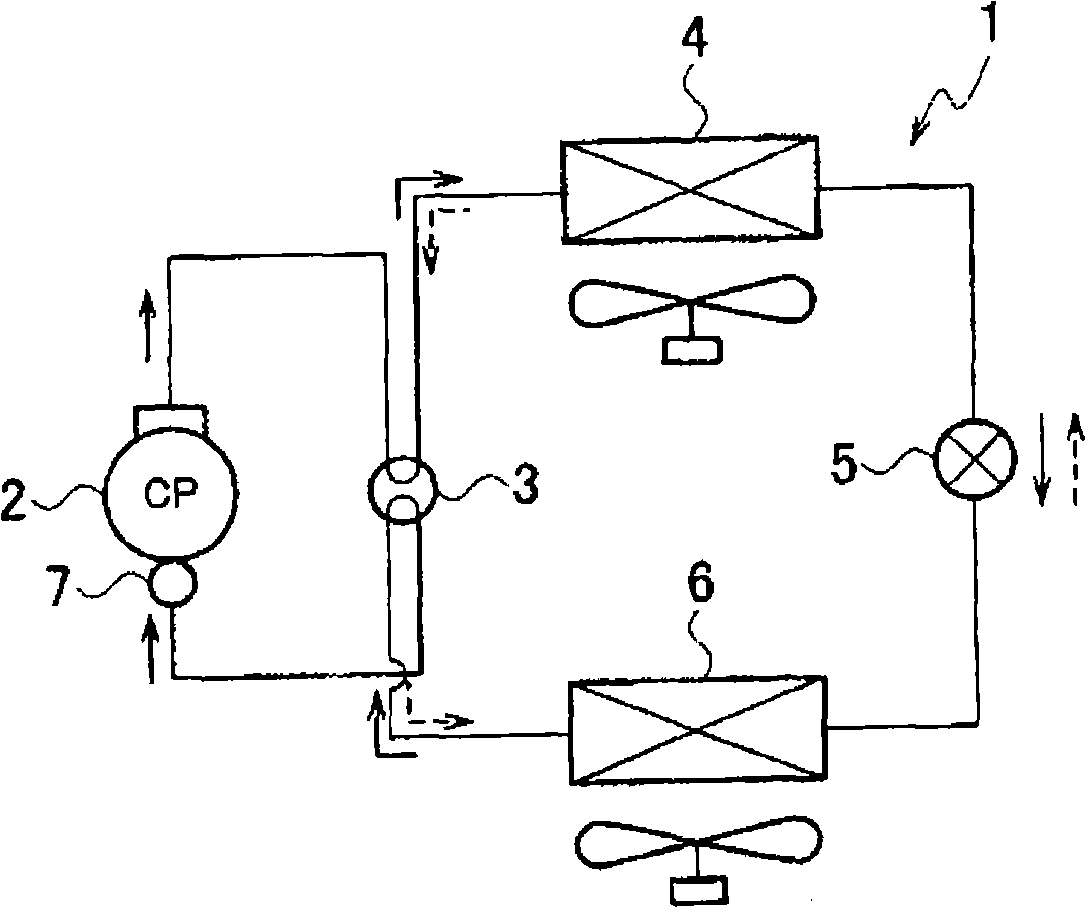

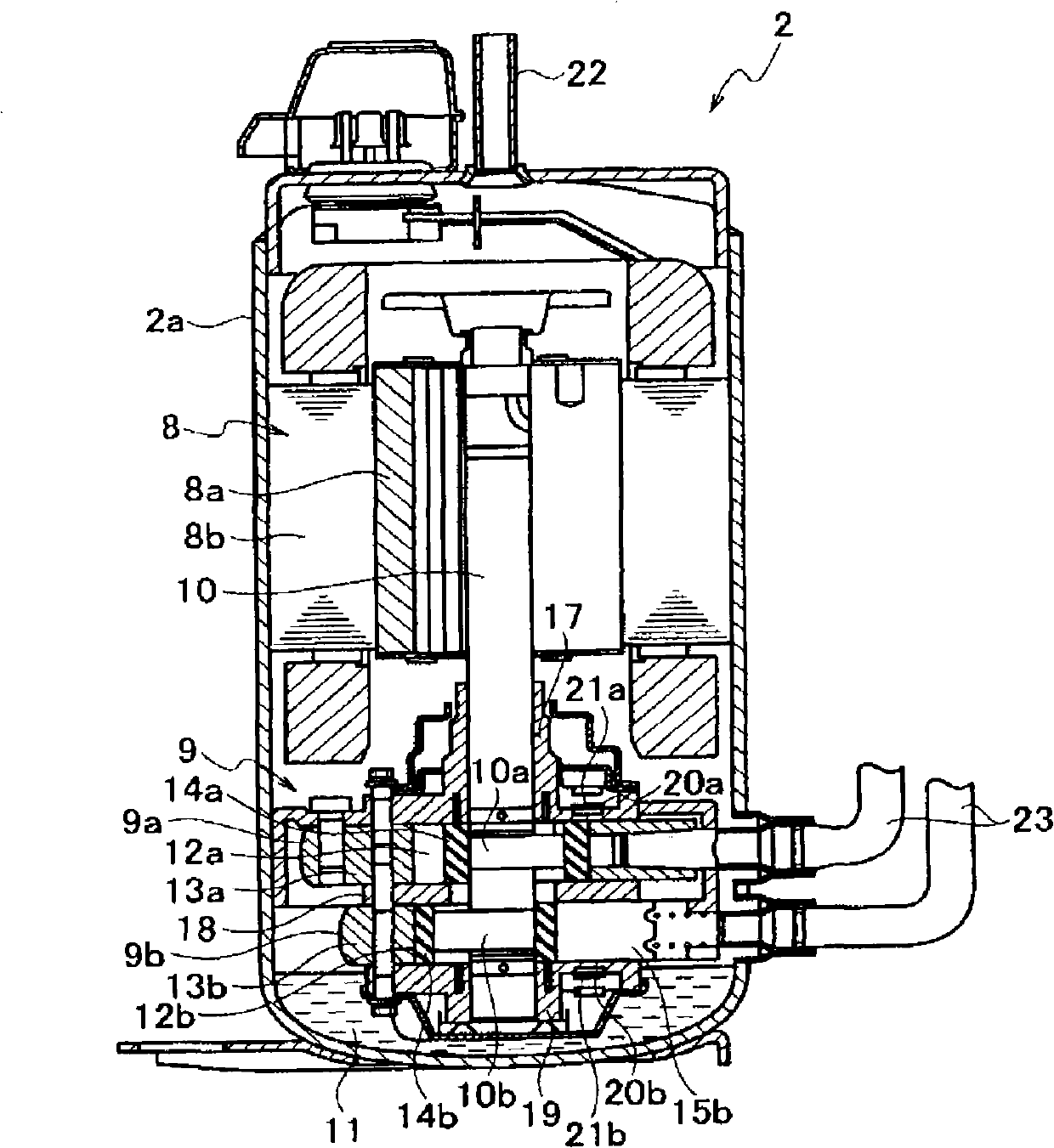

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram which shows the refrigeration cycle apparatus 1 which has a refrigerant compressor.

[0034] The refrigeration cycle device 1 is composed of a closed rotary refrigerant compressor 2, a four-way valve 3, an outdoor heat exchanger 4 that functions as a condenser during cooling operation and an evaporator during heating operation, and an expansion device. 5. The indoor heat exchanger 6, which functions as an evaporator during the cooling operation and functions as a condenser during the heating operation, and the storage tank 7 are connected in a ring and formed.

[0035] In this refrigeration cycle device 1, during the cooling operation, the refrigerant discharged from the refrigerant compressor 2 is supplied to the outdoor heat exchanger (condenser) 4 through the four-way valve 3 as shown by the solid arrow. It is condensed by exchanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com