Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

A scheelite, high-quality technology, applied in the direction of improving process efficiency, calcium/strontium/barium sulfate, etc., can solve the problem of tungsten ore affecting the decomposition rate, etc., to overcome the serious problem of HCl volatilization, reduce costs, and leaching equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Further description will be made below in conjunction with examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

[0035] Example 1

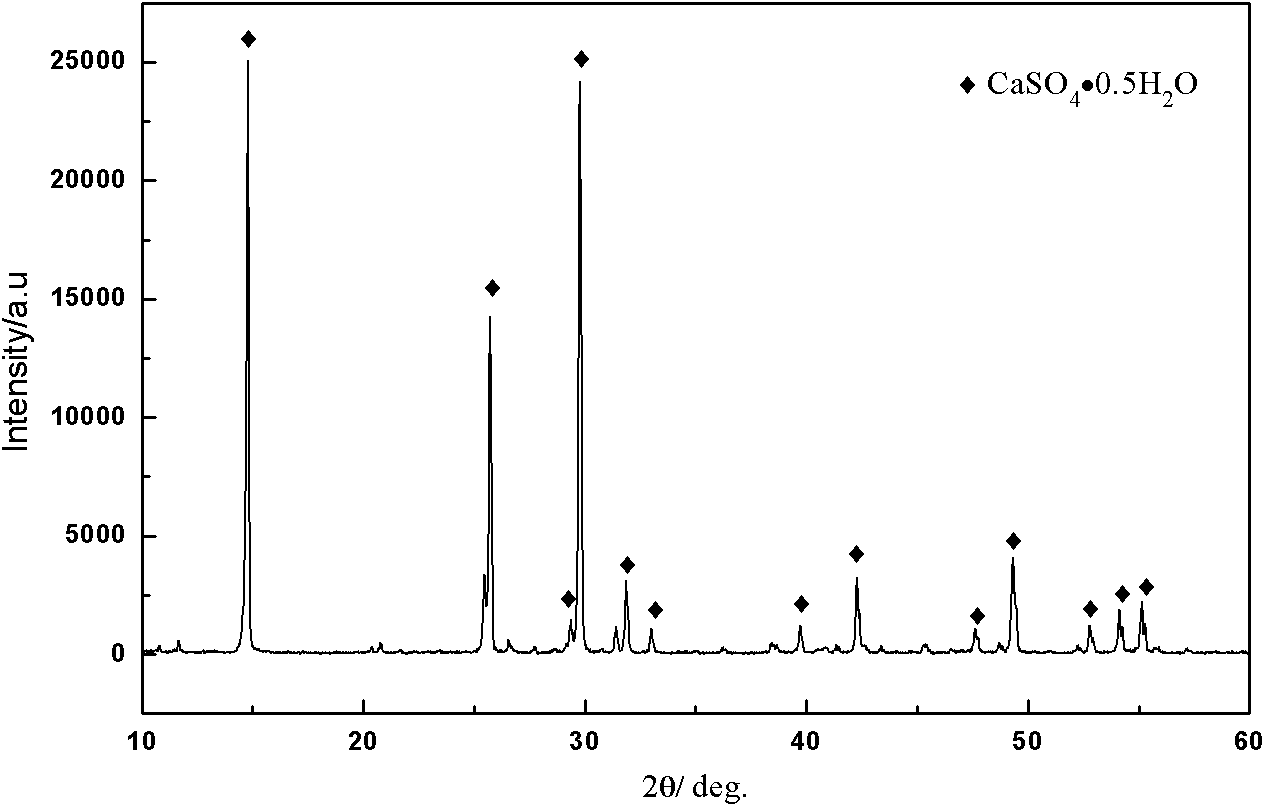

[0036] Scheelite (including WO 3 70.6%) 1kg, prepared P 2 o 5 Phosphoric acid solution with a content of 15%, then add sulfuric acid, control SO in the process 4 2- The concentration is stable at 0.03g / ml, the liquid-solid ratio is 6:1ml / g, the reaction temperature is 60°C, and the reaction time is 4 hours. After sampling and analysis, the leaching rate of tungsten is 94.3%, and the filter residue contains P 2 o 5 was 5.3%. Then transfer the slurry into a crystallization reaction tank for crystallization transformation. The amount of hemihydrate gypsum seed crystals added is 50g, the temperature is raised to 110°C, the crystallization transformation time is 6h, and the tungsten leaching rate is 99.6%. A Buchner funnel with a specification of 200mm was ...

Embodiment 2

[0038] Scheelite (including WO 3 70.6%) 1kg, prepared P 2 o 5 Phosphoric acid solution with a content of 25%, then add sulfuric acid, control SO in the process 4 2- The concentration is stable at 0.05g / ml, the liquid-solid ratio is 5:1ml / g, the reaction temperature is 55°C, and the reaction time is 2h. After the decomposition reaction, the slurry is transferred to the crystallization reaction tank for crystallization transformation. The amount of hemihydrate gypsum seed crystals is 100g, the temperature is raised to 120°C, the crystallization transformation time is 6h, and the tungsten leaching rate is 99.8%. A Buchner funnel with a specification of 200mm was used to filter the slurry, and the time required for filtration was 15 minutes. Then, the filter cake was washed three times with pure water, and the water consumption was 300ml each time. After washing, the filter cake contained P 2 o 5 down to 0.3%. The filtrate uses a secondary amine-based alkaline extractant to ...

Embodiment 3

[0040] Scheelite (including WO 3 70.6%) 1kg, prepared P 2 o 5 10% phosphoric acid solution, then add sulfuric acid, control SO in the process 4 2- The concentration is stable at 0.02g / ml, the liquid-solid ratio is 8:1ml / g, the reaction temperature is 75°C, and the reaction time is 3h. After the decomposition reaction, the slurry is transferred to the crystallization reaction tank for crystallization transformation. The amount of hemihydrate gypsum seed crystal is 1g, the temperature is raised to 100°C, the crystallization transformation time is 4h, and the tungsten leaching rate is 99.5%. A Buchner funnel with a specification of 200mm was used to filter the slurry, and the time required for filtration was 12 minutes. Then, the filter cake was washed with pure water three times, and the water consumption was 300ml each time. After washing, the filter cake contained P 2 o 5 down to 0.2%. The filtrate uses a tertiary amino-based alkaline extractant to extract tungsten, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com