Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of narrow viewing angle, general products without suitable structure, half-tone brightness inversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0450] Hereinafter, the present invention will be described by way of examples, but the present invention is not limited to these examples. Compounds used in Examples are shown below.

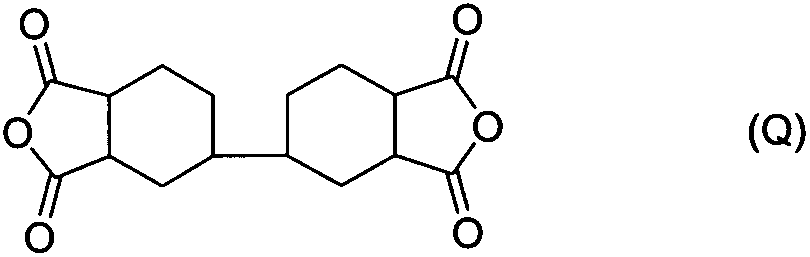

[0451]

[0452] BPDA-H: Dicyclohexanetetracarboxylic dianhydride, formula (Q), manufactured by Iwatani Gas Co., Ltd.

[0453] H-PMDA: cyclohexanetetracarboxylic dianhydride, formula (25)

[0454] CBDA: cyclobutane tetracarboxylic dianhydride, formula (19)

[0455] BTDA: butane tetracarboxylic dianhydride, formula (23)

[0456] PSQ1: 18,21-bis(3-(2,5-dioxotetrahydrofuran-3-yl)propyl)-18,21-dimethyl-1,3,5,7,9,11,13, 15-Octaphenyl-pentacyclo[10.5.1.25, 13.17, 11.19, 15] decasiloxane, formula (S-1)

[0457]

[0458] MBMA: 4,4'-methylenebis(3-methylaniline), formula (VI-1-5)

[0459] DDM: 4,4'-diaminodiphenylmethane, formula (VI-1-1)

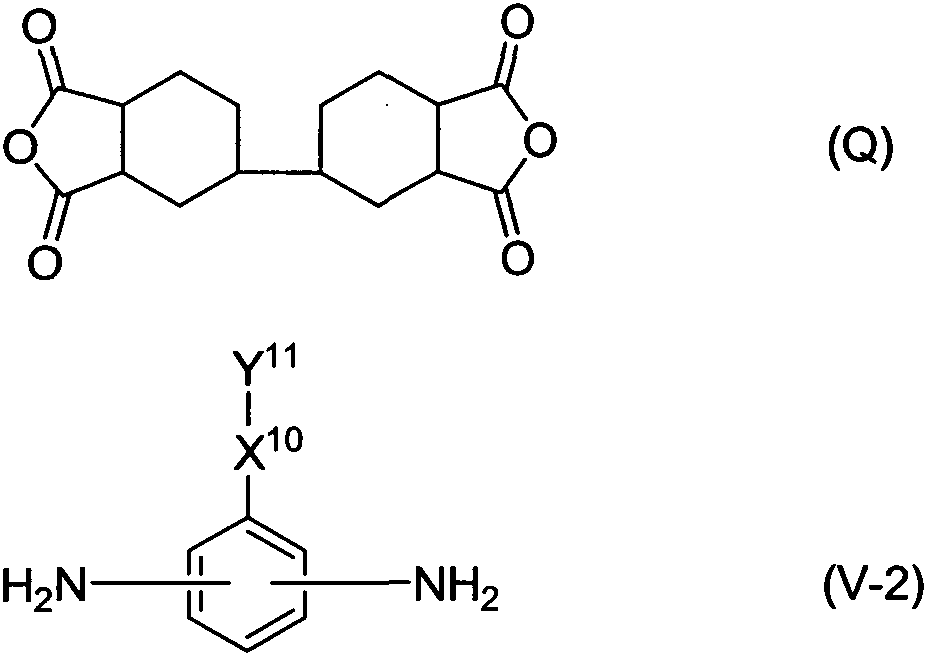

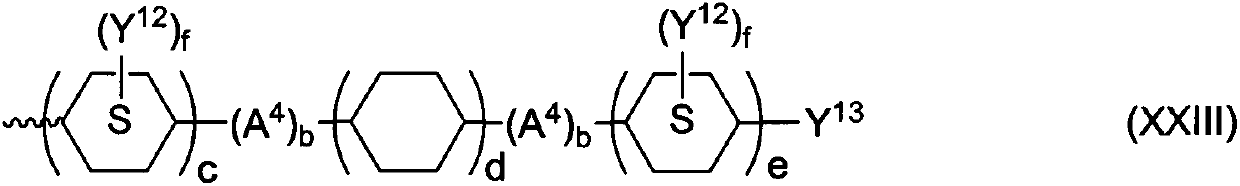

[0460] 5ChCh: 5-{4-[4-(4-n-pentylcyclohexyl)]cyclohexyl}phenylmethyl-1,3-diaminobenzene, Y in formula (V-2-7) 2 Diamines that are alkyl groups of chain len...

Synthetic example 1

[0475] 0.285 g of 5ChCh, 1.341 g of MBMA, and 30.0 g of dehydrated NMP were placed in a 100 ml four-neck flask equipped with a thermometer, a stirrer, a raw material inlet, and a nitrogen inlet, and stirred under a dry nitrogen stream. Next, after adding 1.613 g of BPDA-H and 0.2610 g of BTDA and making it react for 30 hours, 16.5 g of BC was added, and the polyamic-acid solution PA1 whose polymer solid content concentration was 7 wt% was synthesized. When the temperature rises due to the reaction temperature during the reaction of the raw materials, the reaction is carried out while suppressing the reaction temperature to about 70° C. or lower.

[0476] The weight-average molecular weight of polyamic acid is obtained by the following method: the obtained polyamic acid is diluted with phosphoric acid-DMF mixed solution (phosphoric acid / DMF=0.6 / 100, weight ratio) so that the polyamic acid concentration becomes about 1 wt% was measured by the GPC method using a 2695 separation m...

Synthetic example 2

[0480] In addition to changing the tetracarboxylic dianhydride and diamine as shown in Table 1, based on Synthesis Example 1, the solid content concentration of the polymer in which an acid anhydride having a silsesquioxane skeleton was further used in the monomer was prepared as follows: 7wt% polyamic acid solution PA2. Table 1 summarizes the monomer compositions of the polyamic acid solutions of Synthesis Example 1, Synthesis Example 2, and Comparative Example 1 and Comparative Example 2, and the weight average molecular weight of the obtained polymer.

[0481] Table 1

[0482]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com