Production method for liquid-crystal alignment film, liquid-crystal alignment film, liquid-crystal display element, and liquid-crystal alignment agent

A technology of liquid crystal aligning film and liquid crystal aligning agent, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of inability to use heat resistance, low substrate, lower firing temperature, etc., to achieve low residual DC and reduce energy costs. , the effect of high voltage retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0182] Examples are given below and described. In addition, the present invention is not limitedly interpreted by them. The abbreviations used below are as follows.

[0183] (diisocyanate)

[0184] A-1: Tolyl 2,4-diisocyanate

[0185] (tetracarboxylic dianhydride)

[0186] B-1: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0187] (diamine compound)

[0188] C-1: 1-amino-3-aminomethyl-3,5,5-trimethylcyclohexane

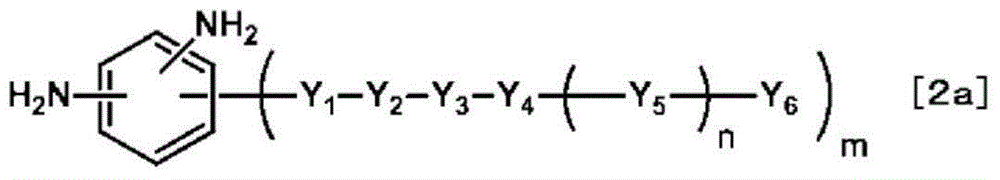

[0189] C-2: N-(3-pyridylmethyl)-3,5-diaminobenzamide

[0190] C-3: 1,3-diamino-4-{4-(4-n-heptylcyclohexyl)phenoxy}benzene

[0191] (Organic solvents)

[0192] NMP: N-methyl-2-pyrrolidone

[0193] BCS: Butyl Cellosolve

[0194] The measurement method performed in this example is shown below.

[0195] (Molecular weight determination of polymer)

[0196] The molecular weights of polyamic acid and polyimide are calculated by measuring the polyamic acid and polyimide with a GPC (room temperature gel permeation chromatography) device, and calculating them as p...

Synthetic example 1

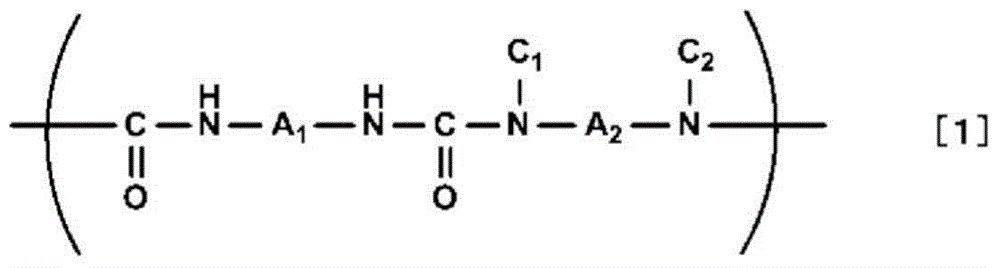

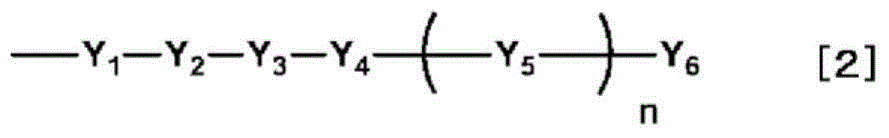

[0209] Mix A-1 (1.56g, 9.00mmol), C-1 (1.53g, 8.98mmol), C-2 (1.30g, 5.36mmol), C-3 (1.37g, 3.59mmol) in NMP (23g) , after reacting at 40°C for 15 hours, add B-1 (1.65g, 8.46mmol), NMP (19g), and then react for 6 hours to obtain polymer solution A (having the repeating unit represented by the above formula [1] Polyamic acid solution) (polymer concentration: 15% by mass). The polymer had a number average molecular weight of 16,020 and a weight average molecular weight of 49,319.

Synthetic example 2

[0211] Mix A-1 (0.783g, 4.50mmol), C-1 (1.53g, 8.98mmol), C-2 (1.30g, 5.36mmol), C-3 (1.37g, 3.59mmol) in NMP (19g) , after reacting at 40°C for 15 hours, add B-1 (2.63g, 13.4mmol), NMP (23g), and then react for 6 hours to obtain polymer solution B (having the repeating unit represented by the above formula [1] Polyamic acid solution) (polymer concentration: 15% by mass). The polymer had a number average molecular weight of 11,555 and a weight average molecular weight of 37,656.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com