Acrylic decolorization resin and preparation method thereof

A decolorizing resin and acrylic technology, applied in the field of polymer chemistry, can solve the problems of poor anti-pollution ability and achieve long service life, strong decolorization ability and good anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of macroporous low-crosslinking resin

[0045] Add 1500ml of no-salt water into a 3000ml reactor equipped with a stirring device, a condensation reflux device and a thermometer, add 10g of gelatin during stirring, heat up to 55°C, and until the gelatin is completely dissolved, add fully mixed 40g of divinylbenzene (content is 55.7%), 320g methyl methacrylate, 40g 4-vinylpyridine, 160g toluene, 2.0g benzoyl peroxide mixture, after the organic mixture forms the uniform droplet of certain size in dispersion medium solution, be warming up to 75 ℃, polymerize for 3 hours, heat up to 80°C and solidify for 5 hours, then raise the temperature to 85°C, continue to solidify for 9 hours, stop the reaction, sieve, wash with a large amount of water, then put the spheres into a Soxhlet extractor, and use Extract with acetone for 12 hours to remove the porogen, and finally wash the acetone in the sphere with water, dry it, and sieve to get 30-70 mesh resin. ...

Embodiment 2

[0046] Embodiment 2: Preparation of macroporous low-crosslinking resin

[0047] Its ratio is: 50g divinylbenzene (content is 55.7%), 100g 4-vinylpyridine, 100g methyl acrylate, 250g 200 # Gasoline, 250g toluene and 2.5g benzoyl peroxide, all the other operations are with reference to embodiment 1.

Embodiment 3

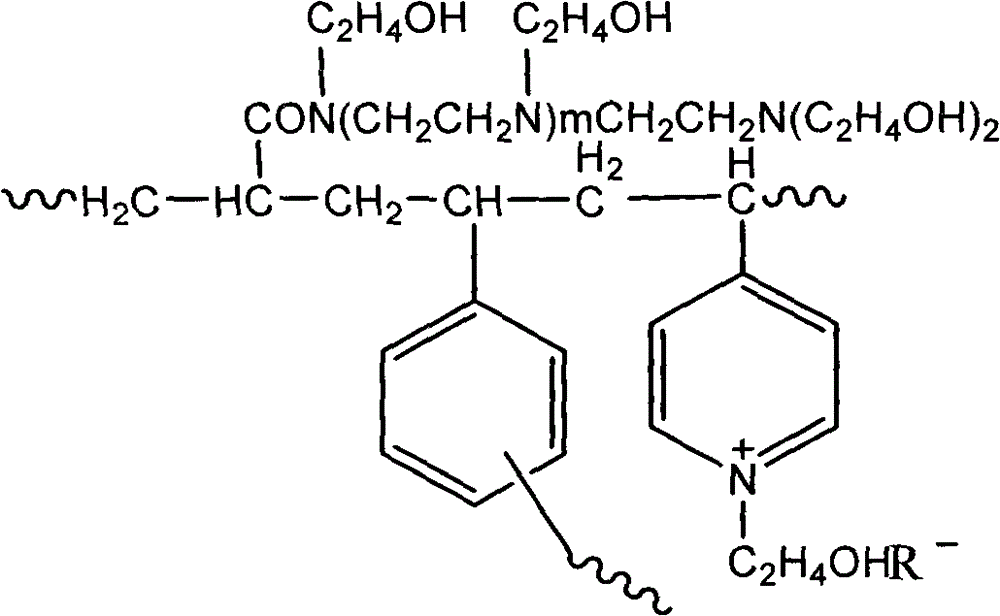

[0048] Embodiment 3: the aminolysis of macroporous type low cross-linking resin obtained in embodiment 1

[0049] Take the white ball of Example 1, add diethylenetriamine 4 times the weight of the white ball, slowly raise the temperature to 150°C, keep it warm for 12 hours, lower the temperature, drain the amine, wash it with methanol, drain it, and wash it with no salt water. An anion resin containing amide bonds and pyridine groups was obtained, and the resin weight exchange capacity was measured to be 9.1 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com