Method for preparing crystalline salicin from salicaceae plants

A salicin and plant technology, applied in the field of plant extraction, can solve problems such as explosion, easy environmental pollution, consumption, etc., and achieve the effects of low production cost, no environmental pollution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

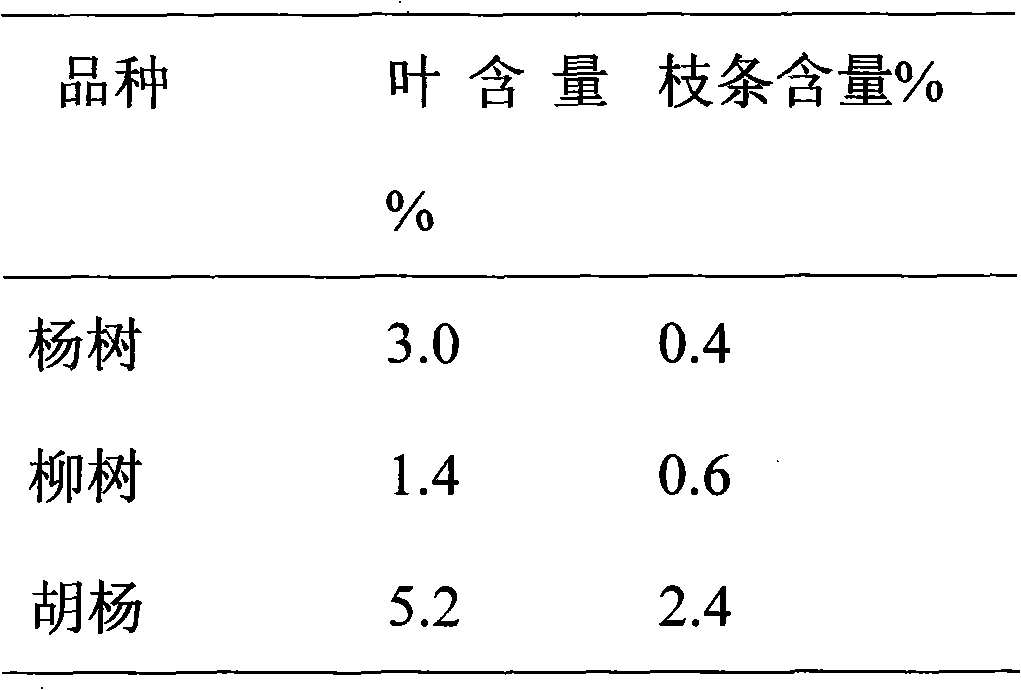

Embodiment 1

[0012] Grind 100kg of harvested willow branches and leaves into 20 meshes, mix in 5% quicklime; soak and extract the mixed raw materials in water for 3 times, each time for 1 hour, and combine the extracts; filter the extracts with a membrane device with a molecular weight of 5000 Impurities were removed; the membrane permeated liquid was collected and concentrated until the specific gravity was 1.10, placed at room temperature for crystallization, and 1.2 kg of crystals were obtained, the crystal content of which was 65% as detected by high performance liquid chromatography.

[0013] Extraction methods using water as a solvent include soaking, percolation and heating under reflux.

[0014] Membrane equipment includes microfiltration or ultrafiltration membrane equipment, and its membrane pore size ranges from 1,000 Daltons to 1 million Daltons according to molecular weight, and from 10 nanometers to 1 micron according to particle size.

[0015] Microfiltration membrane or ult...

Embodiment 2

[0017] Embodiment 2: 100 kg of poplar branches and leaves harvested are crushed into 20 orders, mixed with 5% quicklime; the mixed raw materials are soaked in water and extracted 3 times, each time for 1 hour, and the filtrate is combined; The equipment is used to filter and remove impurities; the membrane permeate is collected and concentrated to obtain 1.5 kg of crystals, which are concentrated to a specific gravity of 1.15 crystals, and the crystal content is 67% as detected by high performance liquid chromatography.

Embodiment 3

[0018] Embodiment 3: The branches and leaves of Populus euphratica harvested are crushed into 20 meshes, mixed with 5% quicklime; the mixed raw materials are soaked and extracted 3 times, each time for 1 hour, and the filtrate is combined; the filtrate is processed by a membrane device with a molecular weight of 50000 Filter to remove impurities; collect the membrane permeate and concentrate until the specific gravity is 1.20 to crystallize to obtain 1.6 kg of crystals, the crystal content of which is 70% as detected by high performance liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com