Method for preparing hollow object by blow molding of zirconia ceramic

A zirconia ceramic and hollow technology, which is applied in the production field of hollow objects, can solve the problems of inability to guarantee dimensional accuracy, difficulty in ensuring firm bonding, low production efficiency, etc., and achieve simple and reliable production process, high yield rate and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

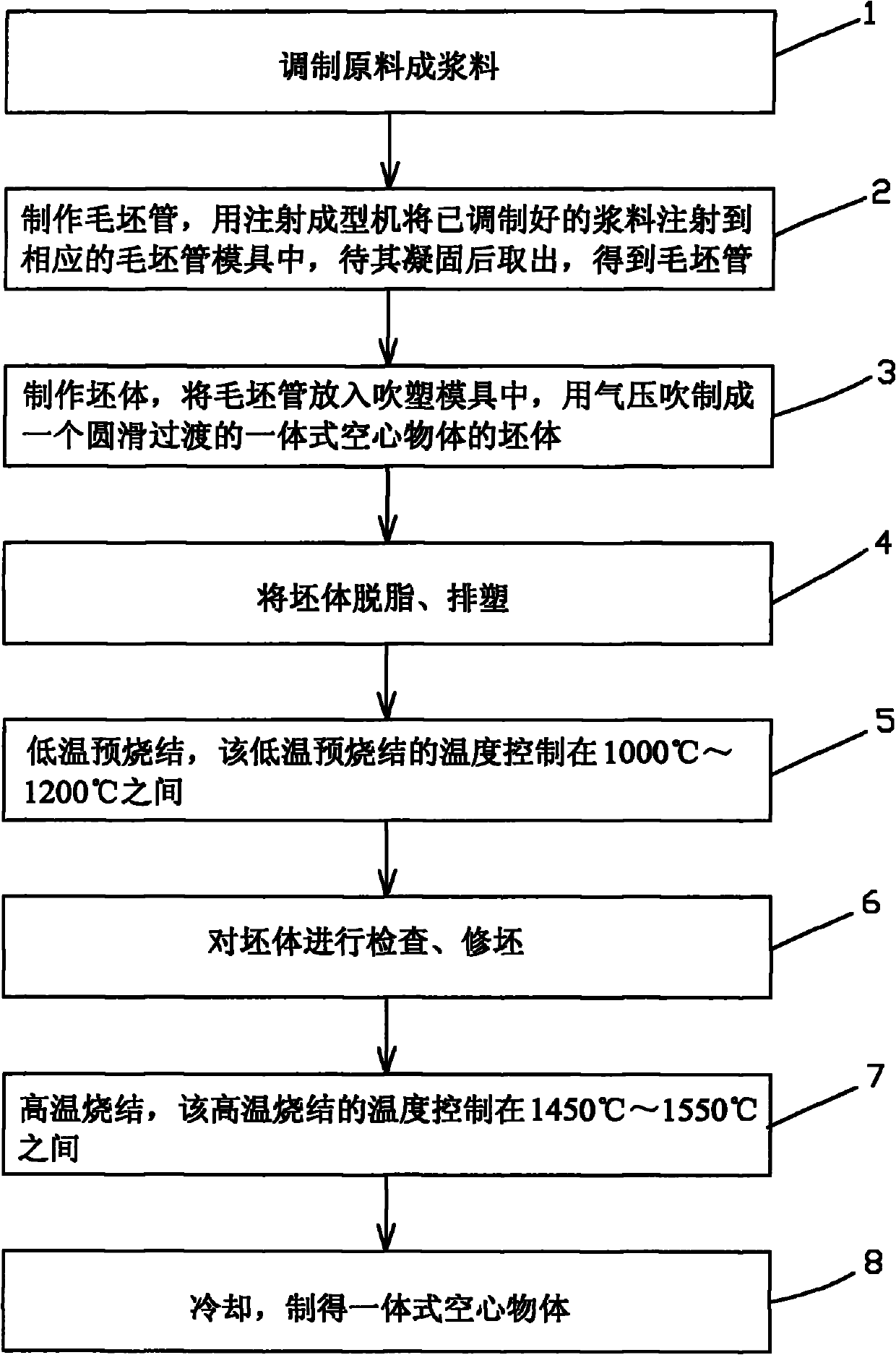

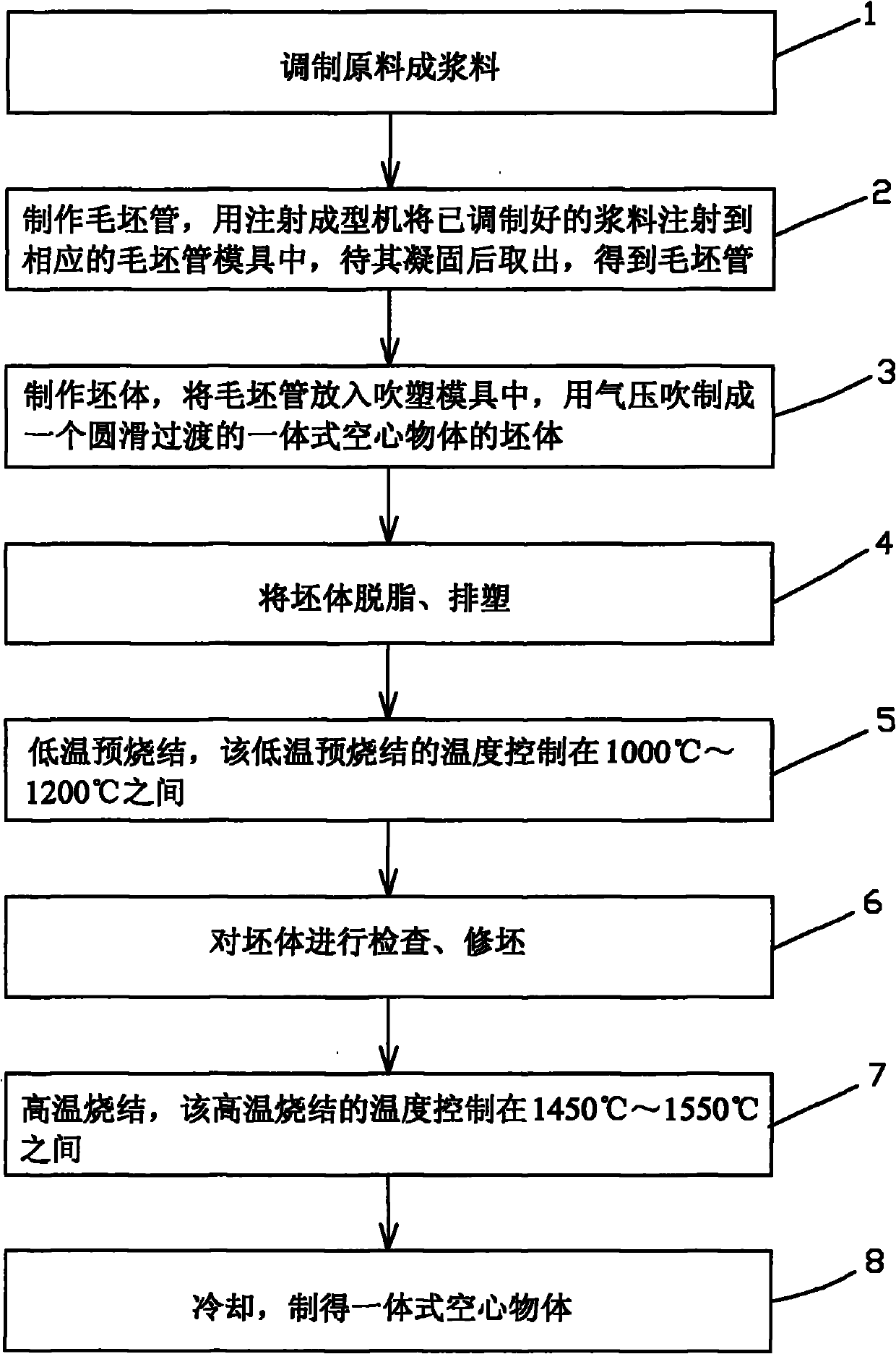

[0027] like figure 1 As shown, the method for making hollow objects by blow molding of zirconia ceramics of the present invention comprises:

[0028] Step 1, preparing raw materials into slurry. The composition and content (in parts by weight) of the raw material are as follows: the composition and content of the raw material are as follows, in parts by weight: 80-90 parts of zirconia, 4-7 parts of paraffin wax; 4-7 parts of microcrystallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com