Column type metal cutting machine

A metal cutting, column-type technology, applied in the field of machine tools, can solve the problems of complex overall structure, large space occupation, and high equipment cost, and achieve the effect of simple overall structure, reduced equipment cost, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

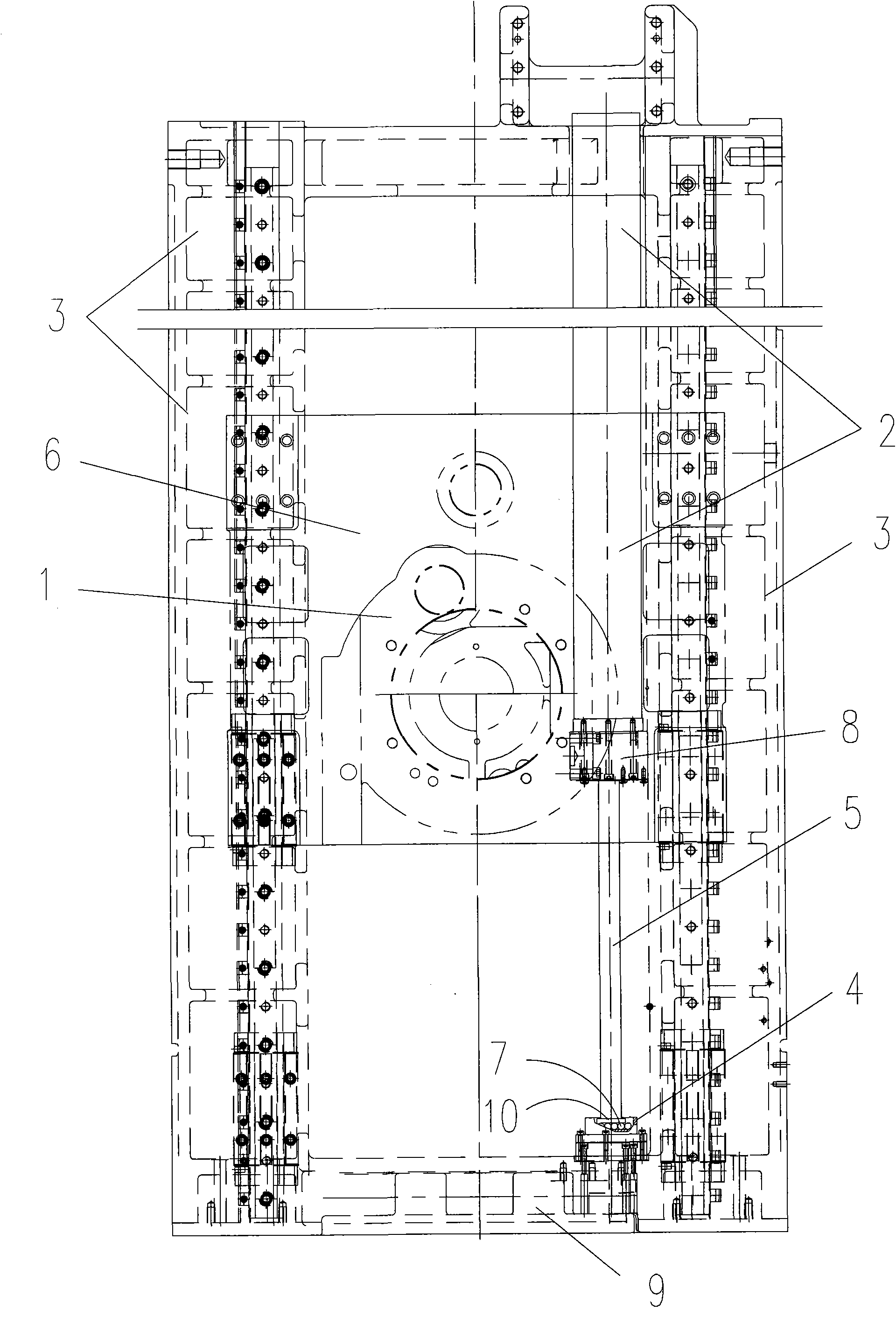

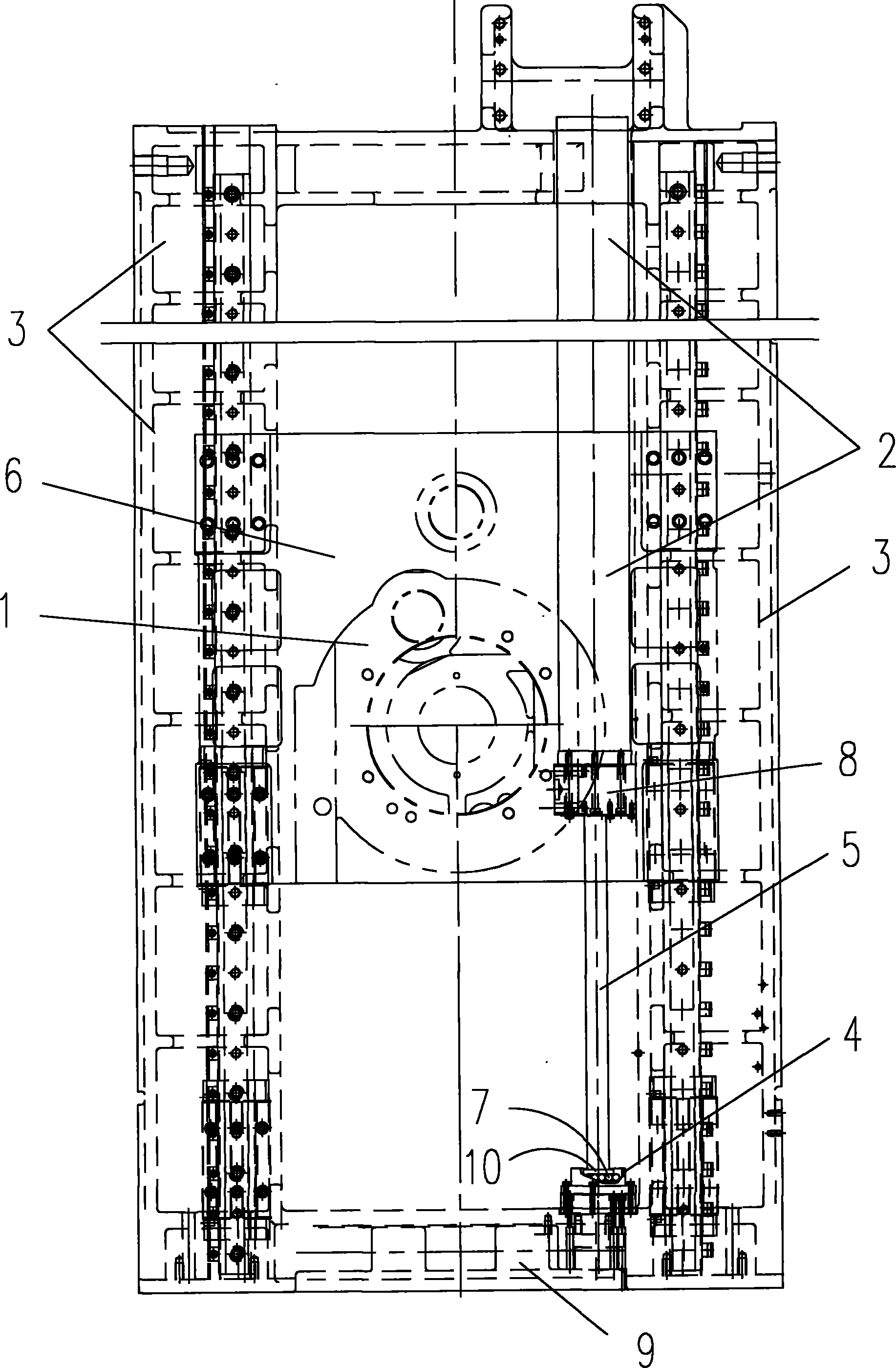

[0008] Such as figure 1 As shown: 3 is a box-type column, forming a frame structure, 6 is a slide plate, and the slideway is connected between the slide plate and the box-type column 3. The slideway can be a linear guide rail type or a dovetail groove structure, and the slideway is set in a vertical direction. , so that the slide plate 6 can move up and down relative to the box-type column 3 driven by the driving mechanism. A headstock 1 is installed on the slide plate 6 . Below the spindle box 1 there is a bed that is connected with the box-type column 3 as one, on the bed is installed a mobile workbench that is connected with the drive mechanism and fixes the workpiece.

[0009] 2 is the optional nitrogen balance cylinder. The lower end of the nitrogen balance cylinder 2 has a mounting seat 8, and the nitrogen balance cylinder 2 is fixedly installed on the box body of the headstock 1 or on the slide plate 6 through the mounting seat 8 and the fixing bolts. Make the nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com