Novel key groove for back-upper heightening of stone-laying gravity dam

A gravity dam and masonry technology, applied in gravity dams, dams, etc., can solve the problems of tensile stress in new concrete, time-consuming and labor-intensive construction, etc., and achieve the effects of improving temperature stress, overcoming difficult procedures, and strong shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

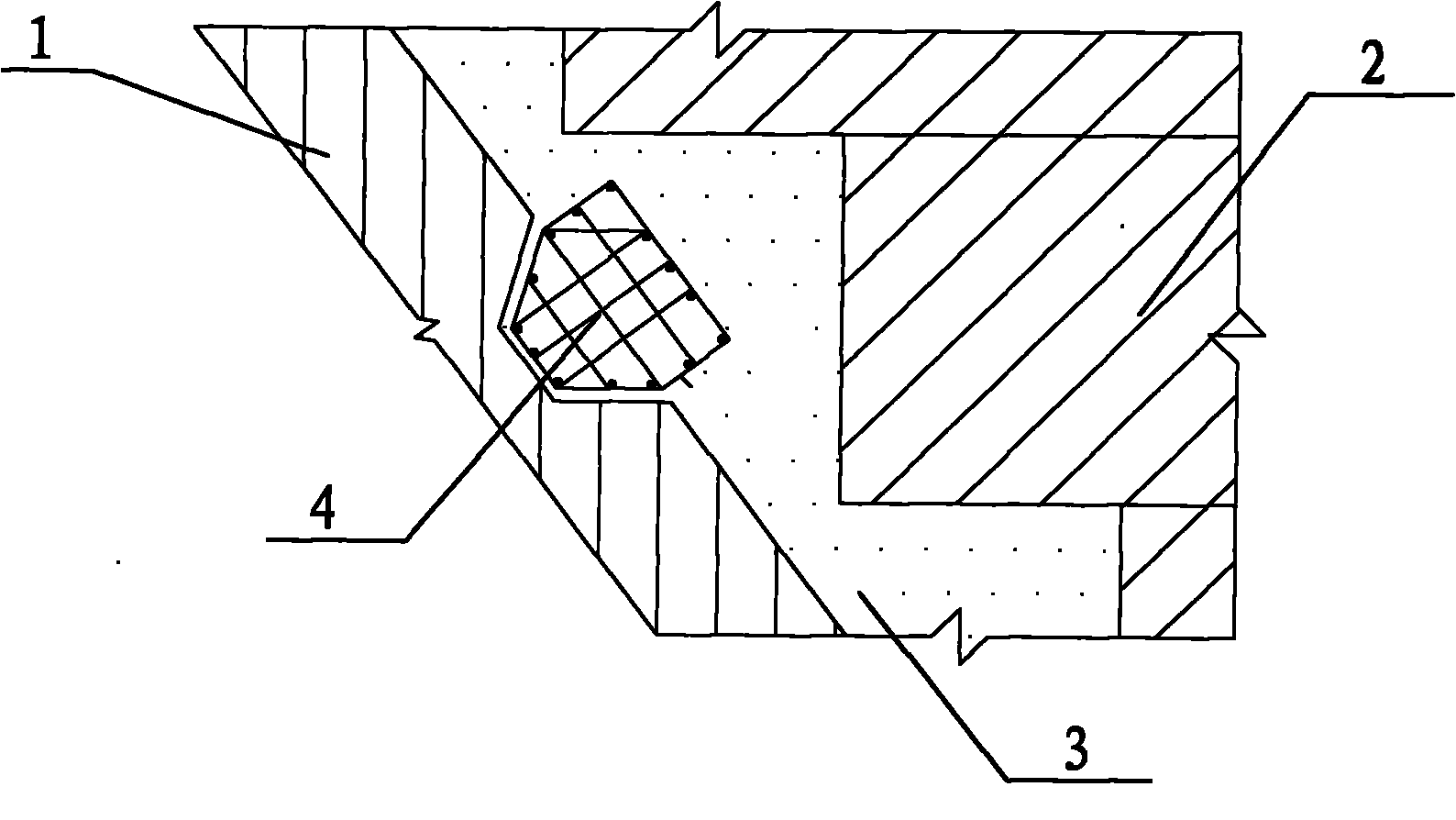

[0018] (1) Embed several shear keys in the original retaining dam section, of which a part of the shear key is buried in the original retaining dam section, and the other part is exposed;

[0019] (2) Simultaneously bury the pre-buried drainage pipe vertically and layeredly in the original retaining dam section; (DN100 soft permeable pipe can be preferably used), which can discharge the seepage water from the original retaining dam section out of the dam body.

[0020] (3) Heightening the retaining dam section, a backfill cavity is formed between the original retaining dam section and its heightened part, so the exposed part of the shear key falls into the backfill cavity, and the drain pipe falls into the The joint surface between the original retaining dam section and the backfill cavity;

[0021] (4) Fill the micro-expansion concrete into the backfill cavity.

Embodiment 2

[0023] The operation of this embodiment is basically the same as that of Embodiment 1, but in this embodiment, the backfill cavity is set in several steps, wherein each step is 2m high and 50cm-200cm wide.

Embodiment 3

[0025] The operation of this embodiment is basically the same as that of Embodiment 1, but in this embodiment, the shear keys are arranged horizontally in rows at fixed vertical intervals. Wherein the longitudinal section of the part of the shear key embedded in the original retaining dam section is set to be trapezoidal, and the longitudinal section of the part embedded in the backfill cavity is set to be rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com