Method for pulping and making paper by using eucalyptus bark

A technology of eucalyptus bark and bark is applied in the field of papermaking using eucalyptus bark, which can solve the problems of difficulty in resource collection, classification, distribution and use, high papermaking cost, and many pollutants, etc., and achieves a practical and feasible process, low cost, and reduced Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

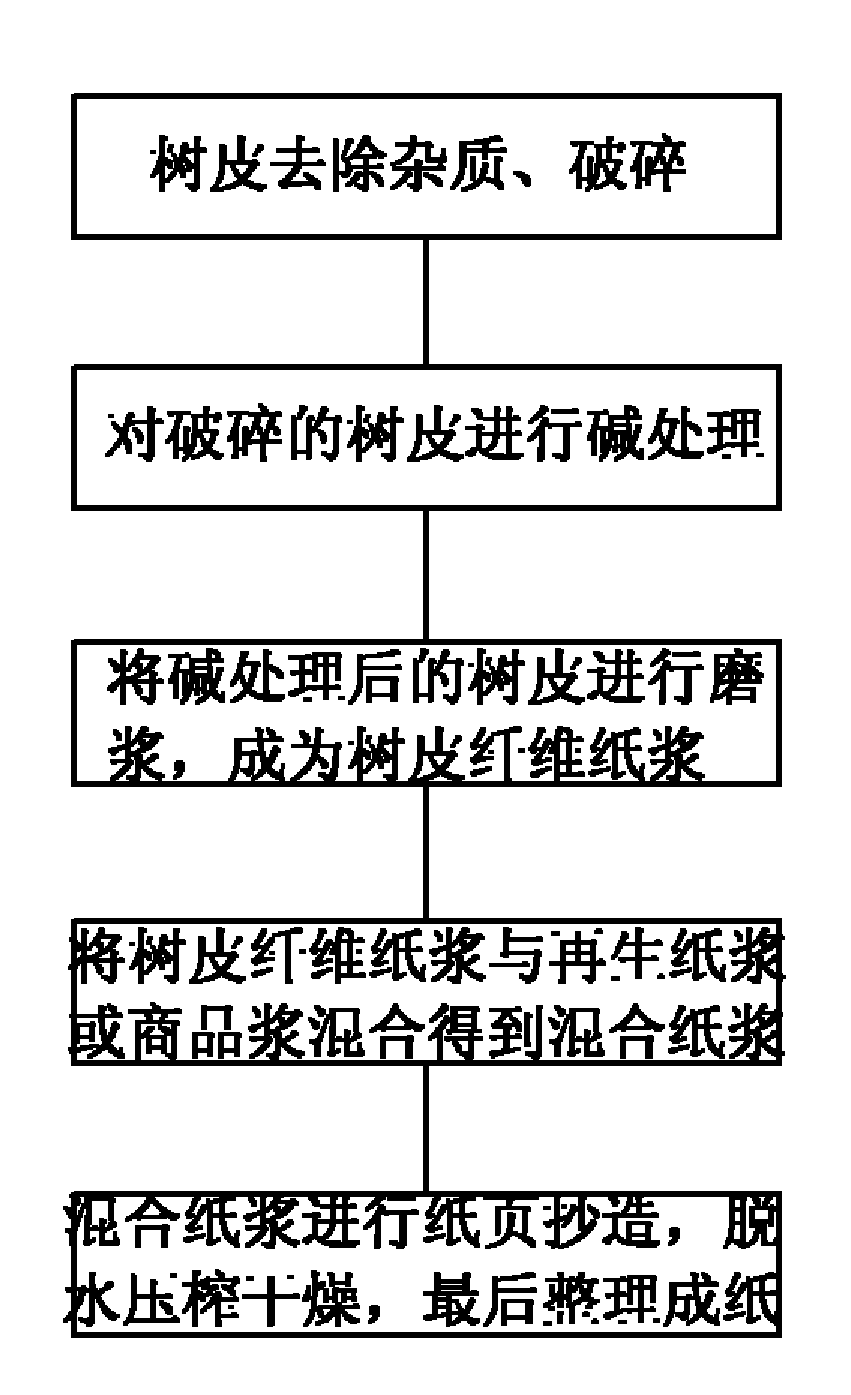

[0034] Present embodiment carries out papermaking utilization analysis explanation with Eucalyptus urophylla bark, utilizes the method for making corrugated paper from Eucalyptus urophylla bark, as figure 1 shown, including the following steps:

[0035] 1) The bark is removed from impurities, and then broken into filaments. After the bark is broken, the bark particles are extracted with hot water at 60°C to remove the soluble matter in the bark;

[0036] 2) Alkali treatment of broken bark;

[0037] 3) The bark after alkali treatment is subjected to high-consistency grinding to form coarse pulp with a concentration of 5%; then disc grinding is performed to form bark fiber pulp;

[0038] 4) Mixing bark fiber pulp and recycled pulp at a volume ratio of 0.1:1 to obtain mixed pulp;

[0039] 5) Mix the pulp for paper sheet making, dehydration, pressing and drying, and finally arrange it into paper.

[0040] Analysis table for making corrugated paper from eucalyptus bark

[0041]...

Embodiment 2

[0043] Present embodiment carries out papermaking utilization analysis explanation with Eucalyptus urophylla bark, utilizes the method for making corrugated paper from Eucalyptus urophylla bark, as figure 1 shown, including the following steps:

[0044] 1) The bark is removed from impurities, and then broken into filaments. After the bark is broken, the bark particles are extracted with 80°C hot water to remove the soluble matter in the bark;

[0045] 2) Alkali treatment of bark particles;

[0046] 3) The bark after alkali treatment is subjected to high-consistency grinding to form coarse pulp with a concentration of 15%; then disc grinding is performed to form bark fiber pulp;

[0047] 4) Mixing bark fiber pulp and recycled pulp at a volume ratio of 0.5:1 to obtain mixed pulp;

[0048] 5) Mix the pulp for paper sheet making, dehydration, pressing and drying, and finally arrange it into paper.

[0049] Analysis table for making corrugated paper from eucalyptus bark

[0050...

Embodiment 3

[0052] Present embodiment carries out papermaking utilization analysis explanation with Eucalyptus urophylla bark, utilizes the method for making corrugated paper from Eucalyptus urophylla bark, as figure 1 shown, including the following steps:

[0053] 1) Remove impurities from the bark, and then break it into flakes. After breaking the bark, extract the bark particles with 100°C hot water to remove the soluble matter in the bark;

[0054] 2) Alkali treatment of bark particles;

[0055] 3) The bark after alkali treatment is subjected to high-consistency grinding to form coarse pulp with a concentration of 35%; then disc grinding is performed to form bark fiber pulp;

[0056] 4) Mix bark fiber pulp and recycled pulp at a volume ratio of 1:1 to obtain mixed pulp;

[0057] 5) Mix the pulp for paper sheet making, dehydration, pressing and drying, and finally arrange it into paper.

[0058] Analysis table for making corrugated paper from eucalyptus bark

[0059] [001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com