Leakproof flexible container bag

A technology of container bags and flexible bags, applied in the field of leak-proof flexible container bags, can solve the problems of increasing the difficulty of loading and unloading, leakage, leakage at seams, etc., and achieve the effect of practical and feasible process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

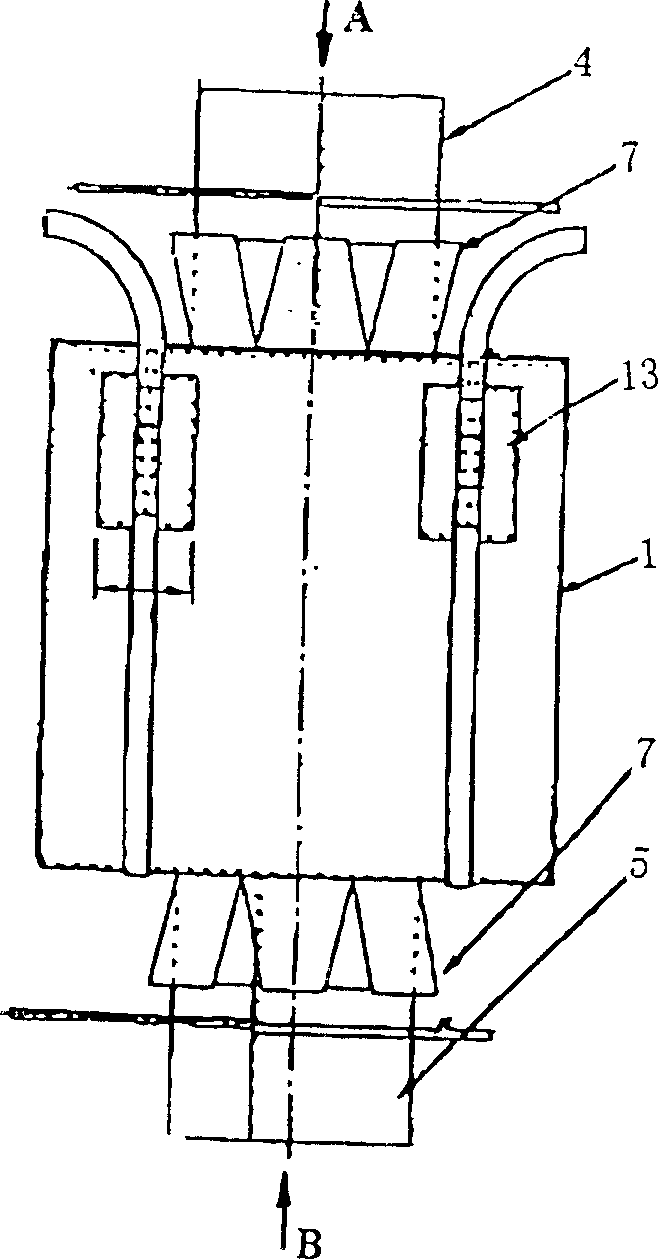

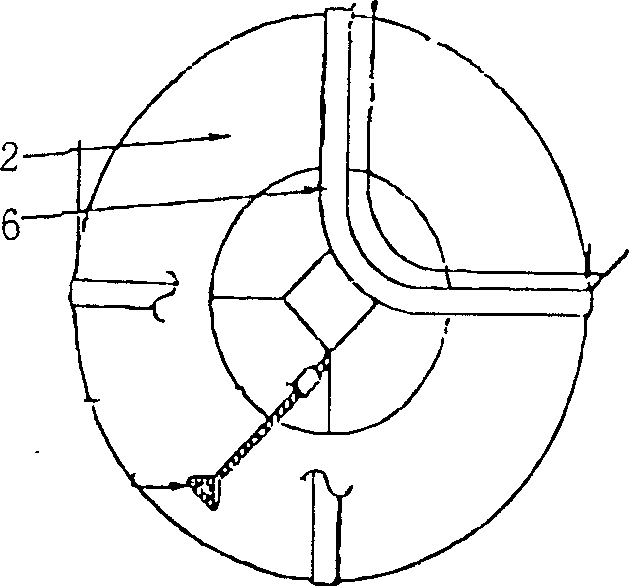

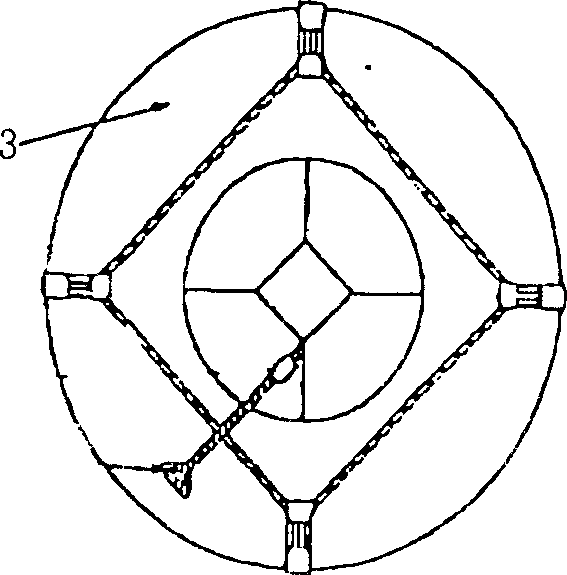

[0033] Figure 1 to Figure 10 Figure 1 of this example is given. see Figure 1 ~ Figure 3 , the flexible bag body 1 adopts circular weaving tubular cloth to form. The upper cover 2 and the lower bottom 3 are located on and below the bag body and are sewed into one body with the bag body. One end of the upper inlet 4 and the lower outlet 5 is respectively sewed with the loam cake, the lower bottom and the body of the bag as a whole and there is a reinforcement 13 thereon. The upper entrance and the lower exit are respectively connected with fork reinforcement 7 by sewing. Each sewing seam is made with Figure 4 ~ Figure 6 The outsourcing method or the internal blocking method as shown in Figure 7 and Figure 8 or the Figure 9 , Figure 10 The interlining method shown uses leak-proof parts to prevent leakage.

[0034] Figure 4 ~ Figure 6 It is a schematic diagram of leakage prevention by outsourcing. That is, at the sewing seam of the woven cloth, the sewing edge is wr...

Embodiment 2

[0038] Figure 11 ~ Figure 13 Figure 2 of Embodiment 2 of the present invention is given. The present embodiment 2 is basically the same as that of embodiment 1. The difference is that the flexible bag body 1 is made into flat cloth by a flat loom and then drenched, and then stitched together to form a cylindrical bag body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com