Oil separator for separating oil from aerosols in internal combustion engines, internal combustion engines and motor vehicles

一种油分离器、内燃机的技术,应用在机器/发动机、分离方法、弥散粒子分离等方向,能够解决进气阀燃烧室结焦等问题,达到低复杂度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

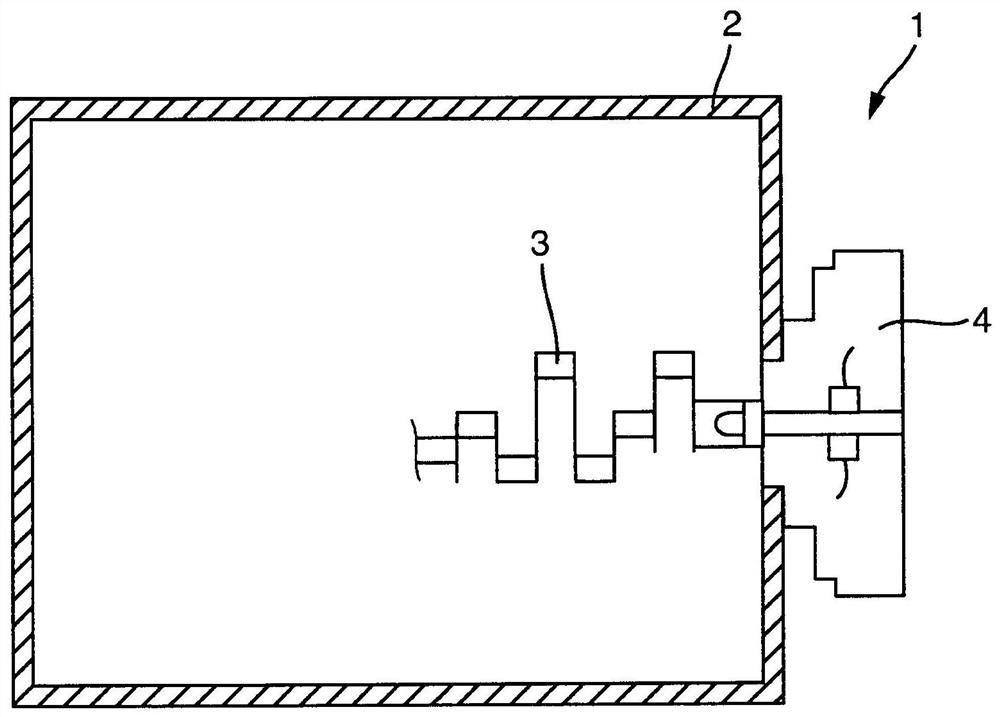

[0018] figure 1 An internal combustion engine 1 for a motor vehicle is shown schematically. Internal combustion engine 1 has a crankcase 2 and a crankshaft 3 to which an oil separator 4 according to the invention can be coupled.

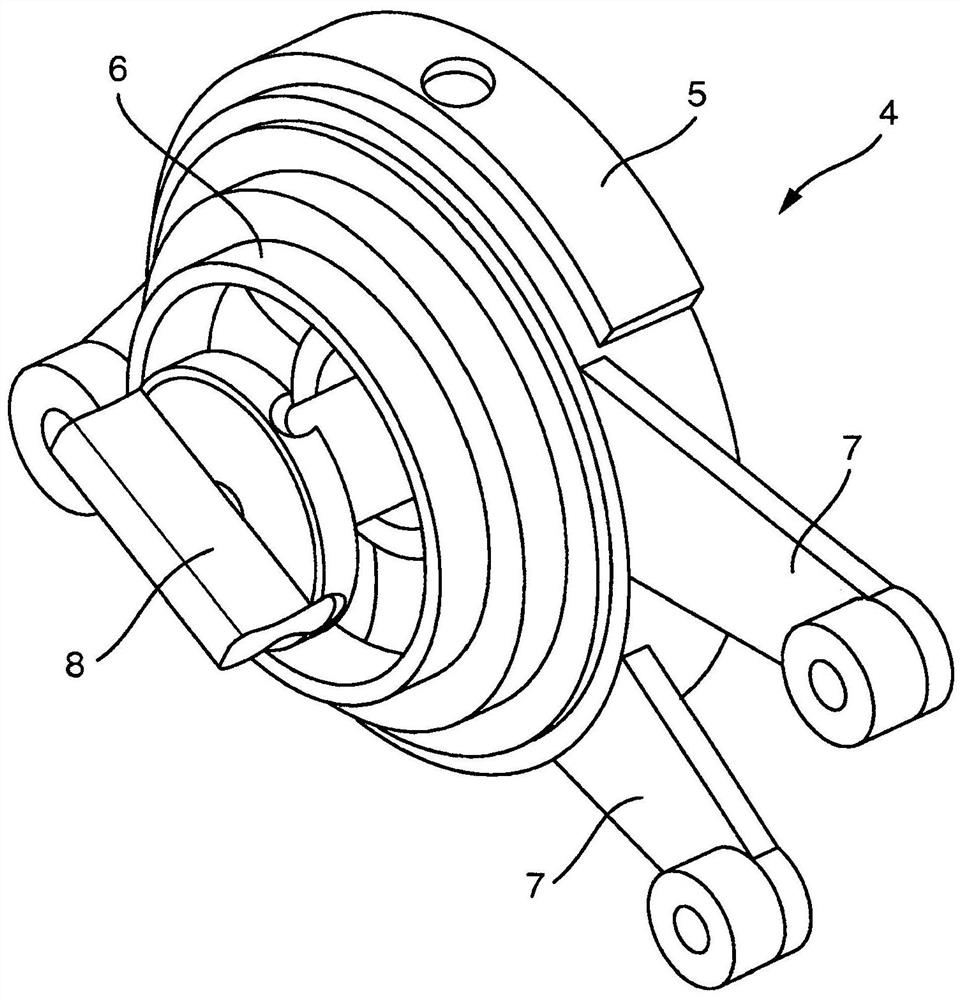

[0019] figure 2 A three-dimensional view of an oil separator 4 according to the invention is shown. The oil separator has a housing 5 with a flange neck 6 which can be inserted into the crankcase 2 and a fastening arm 7 with which the housing 5 can be fastened on the on crankcase 2. Via the engagement element 8 the oil separator 4 can be coupled to the crankshaft 3 and can be driven by it.

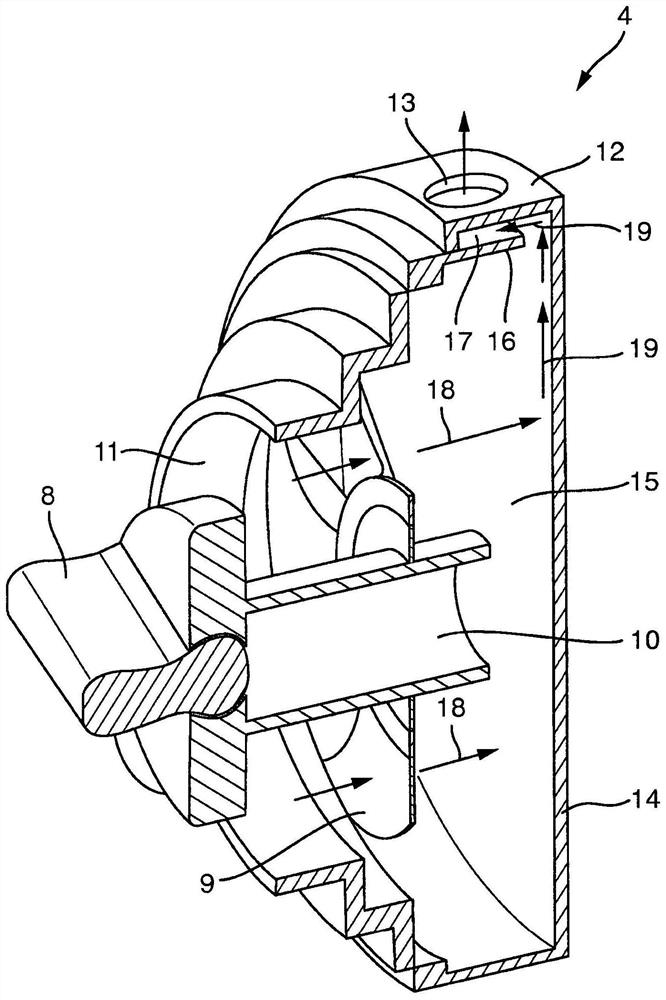

[0020] image 3 Shows figure 2 A three-dimensional cross-sectional view of the oil separator 4 in, wherein, image 3 is a sectional view along the rotation axis of the impeller 9 . Said impeller 9 is an axial impeller, ie, when rotating about its axis of rotation, the impeller 9 produces a flow parallel to its axis of rotation. The impeller 9 is mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com