Weft inserting mechanism of sample loom

A technology of weft insertion mechanism and loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of cloth surface pollution, cylinder vulnerability, etc., to solve cylinder vulnerability, solve cloth surface pollution, and avoid compressed air Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

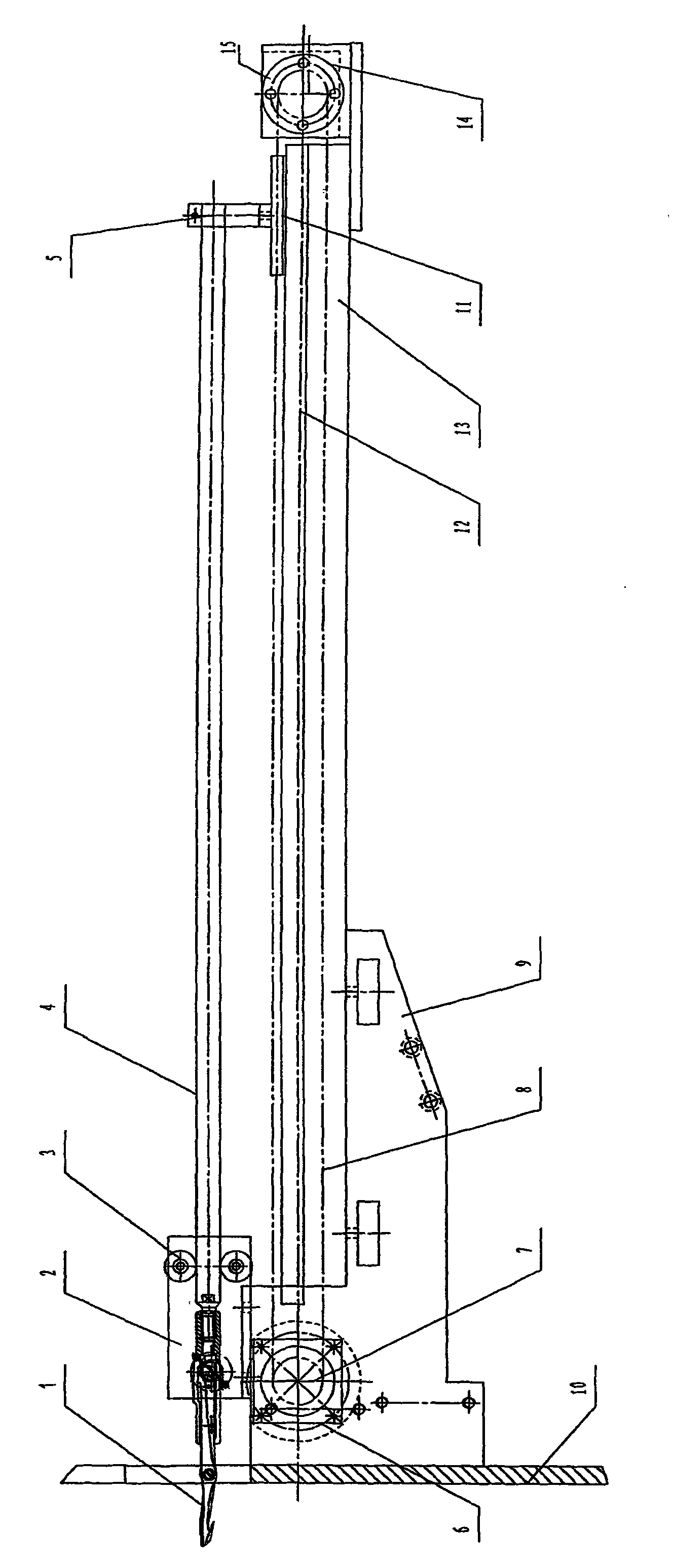

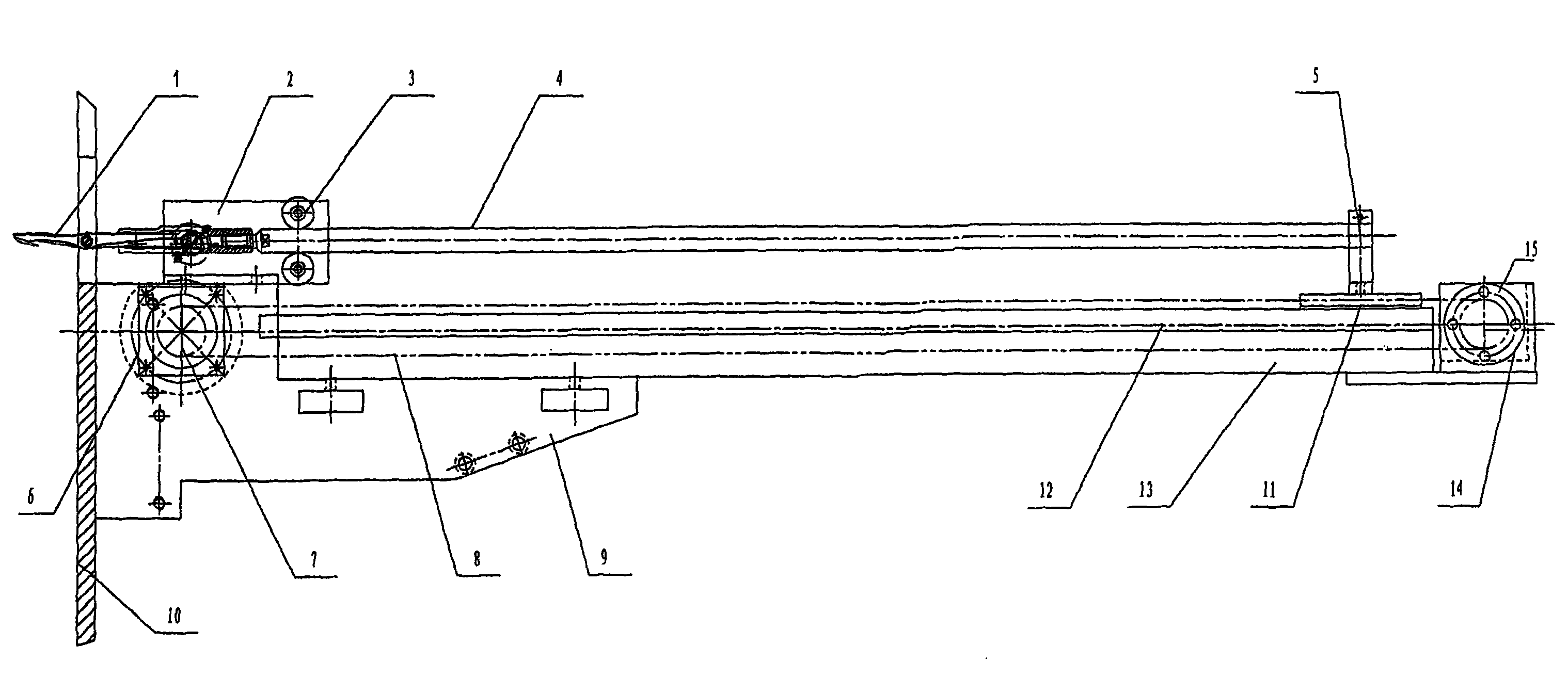

[0014] see figure 1 , the weft insertion mechanism of the sample loom involved in the present invention mainly consists of rapier head 1, rapier 4, guide wheel 3, rapier seat 5, guide wheel support 2, rigid support 9, linear bearing slider 11, linear Guide rail 12, cantilever support 13, right wallboard 10, servo motor 6, synchronous belt pulley I 7, synchronous belt wheel support 14, synchronous belt wheel II 15 and synchronous belt 8 form.

[0015] The rapier head 1 is installed on the top of the rapier 4, the two ends of the rapier 4 are fixed by the guide wheel 3 and the rapier seat 5, the guide wheel 3 is installed on the guide wheel support 2, and the guide wheel support 2 is installed on the rigid support 9, the rapier seat 5 is installed on the linear bearing slider 11, the linear bearing slider 11 is placed on the linear guide rail 12, the linear guide rail 12 is installed on the cantilever bracket 13, and one end of the cantilever bracket 13 is installed on the rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com