Gold plating solution for plating gold finger on circuit board

A gold finger and gold electroplating technology, applied in the field of electroplating, can solve the problems of poor electrical performance, anti-corrosion performance and welding performance, easy gold discoloration, uneven thickness, etc., to promote uniform catalytic nucleation, smooth coating, Mitigating the effect of plating pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

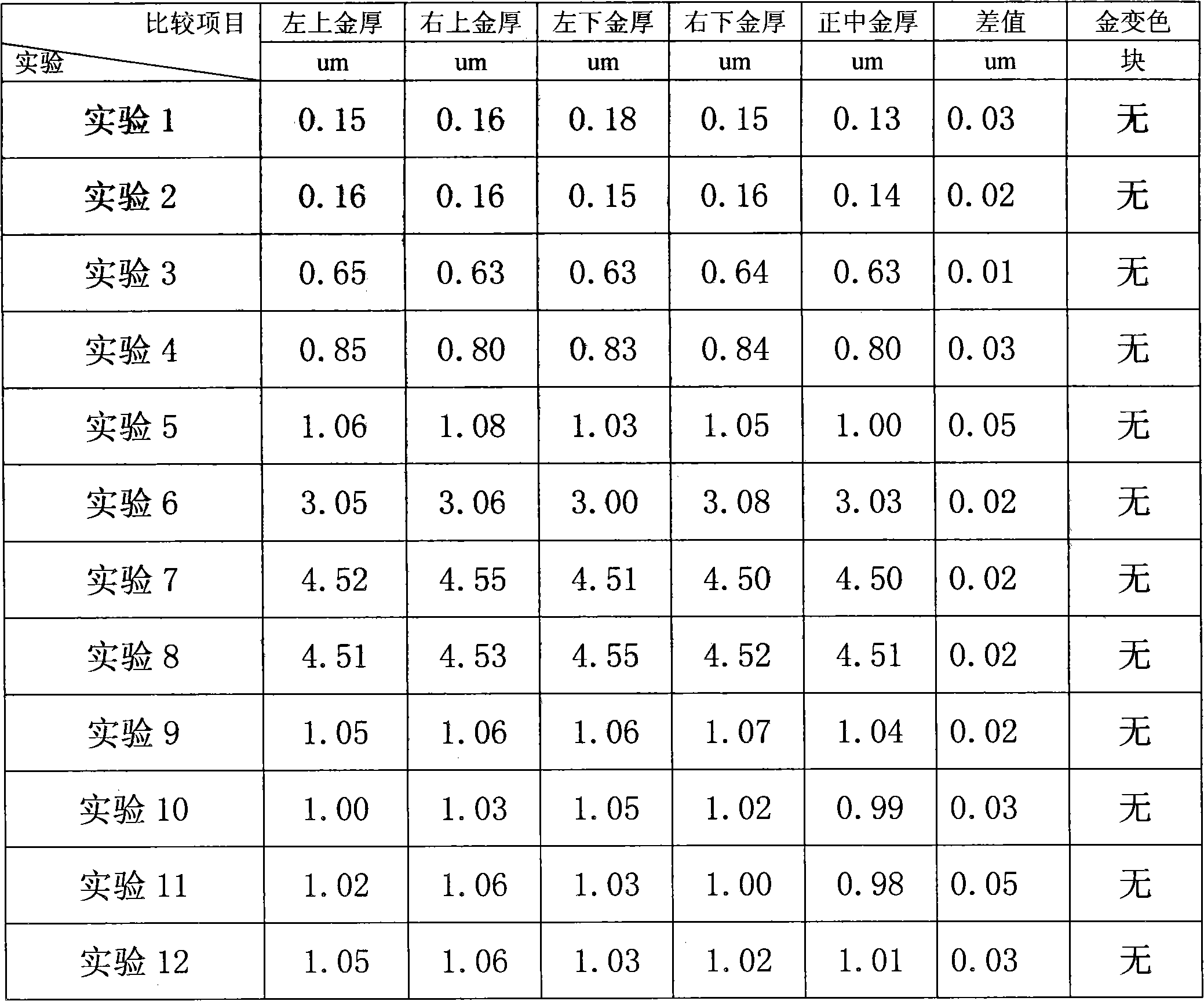

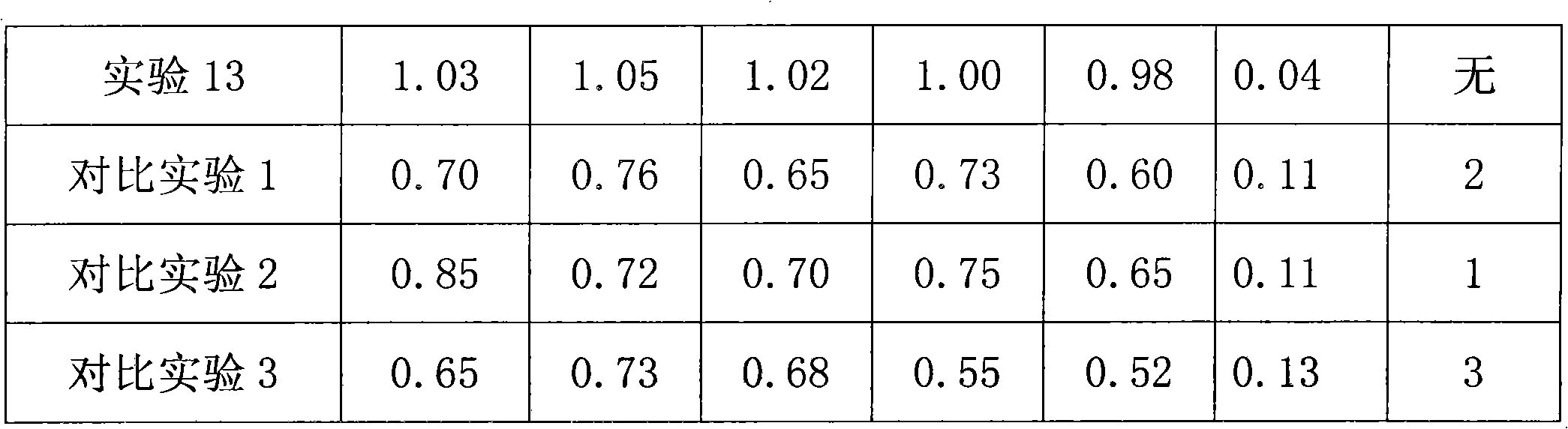

[0019] Prepare the electroplating gold solution 1 in the circuit board electroplating gold finger gold cylinder, take 20 pieces of the circuit board after conventional process operation to nickel plating, then carry out acid leaching in a conventional manner, then enter the gold cylinder containing electroplating gold solution 1, and turn on the power , after electroplating in a gold tank for 5 minutes, take it out, wash it with regular water, and dry it.

[0020] Cut out the upper left edge point (abbreviated as upper left), upper right edge point (abbreviated as upper right), lower left edge point (abbreviated as lower left), lower right edge point (abbreviated as lower right) and gold-plated layer in the middle (abbreviated as lower right) of each drying circuit board. The circuit board, along the thickness direction. Slice the excised material to observe the thickness of the gold plating, and observe the discoloration of the gold after leaving the uncut circuit board for 1...

Embodiment 2

[0024] Except that the electroplating gold solution is different, other is the same as embodiment 1.

[0025] Electroplating gold solution 2 is: gold content 1g / l (potassium gold cyanide), conductive salt 0.05g / l (citrate), metallic luster 0.05g / l (CuMn 2 o 4 ), organic gloss agent 0.05g / l (2,3-diaminopyridine), wetting agent 0.05g / l (sodium lauryl sulfate), appropriate amount of compounding agent (EDTA), appropriate amount of buffer solution, and the balance is water .

Embodiment 3

[0027] Except that the electroplating gold solution is different, other is the same as embodiment 1.

[0028] Electroplating gold solution 3 is: gold content 4.8g / l (potassium gold cyanide), conductive salt 0.1g / l (citrate), metallic luster 0.1g / l (CuMn 2 o 4 ), organic gloss agent 0.1g / l (2,3-diaminopyridine), wetting agent 0.1g / l (sodium lauryl sulfate), appropriate amount of compounding agent (EDTA), appropriate amount of buffer solution, and the balance is water .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com