Vacuum photoconductive molecular/atomic gas micro-injection device

An atomic gas and micro-spray technology, which is applied in vacuum evaporation coating, melting spray coating, sputter coating and other directions, can solve the problems of difficulty in precise control of spray materials, waste of materials, and difficulty in grasping the range of jet/vapor action. The effect of saving material, reducing process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

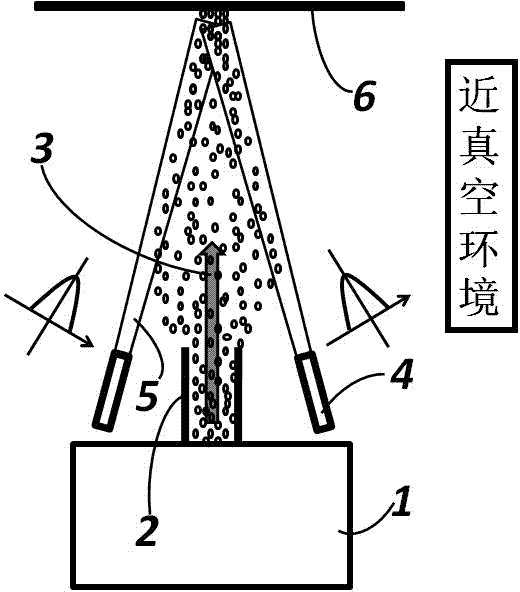

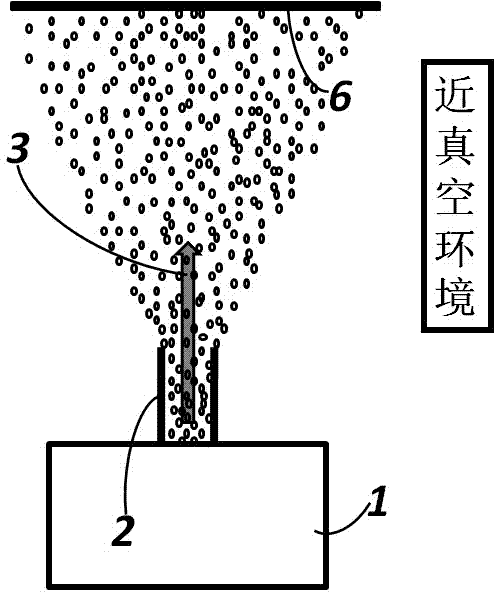

[0037] Embodiment one: see figure 1 , The vacuum photoconductive molecular / atomic gas micro-injection device is composed of a gas source 1, a spray nozzle 2, and a guiding light source 4. The device works in a near-vacuum environment, and the environmental pressure should be kept below 0.3 atmospheric pressure. The gas source 1 is connected to the injection nozzle 2 and generates molecular / atomic gas. Under the pressure inside the gas source 1, the molecular / atomic gas jet 3 is ejected from the injection nozzle 2; the guiding light source 4 generates a strong beam 5, and there is a The target disk 6 forms a near-enclosed area, and the molecular / atomic gas jet 3 shoots forward in this area to finally achieve the purpose of directional / fixed-point injection.

Embodiment 2

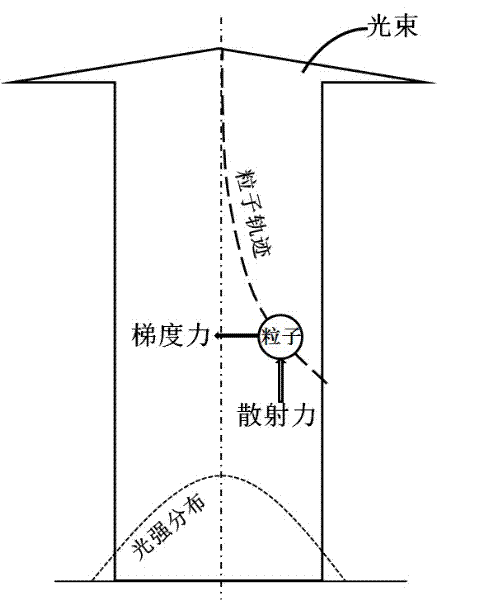

[0038] Embodiment two: see figure 1 and image 3 , the particles ejected from the ejection nozzle 2 move forward into the light field emitted by the strong beam 5, and the intensity of the light field has a certain distribution. In the light field, the particle receives two forces exerted by the light beam on it, one is the scattering force along the direction of the optical axis (usually the light pressure), and the other is the gradient force of the light field perpendicular to the direction of the optical axis. Under the action of the scattering force, the particles accelerate along the direction of the optical axis, and under the action of the gradient force of the light field, the particles will move towards the region with the highest intensity of the light field. Therefore, when the light intensity and its light field gradient are large enough, under the action of these two forces, the particles will eventually overcome the scattering caused by the diffusion process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com