Uniform charging method of bell-less blast furnace

A technology of uniform material distribution and blast furnace, applied in the direction of bell and funnel arrangement, etc., can solve the problems of poor material connection, failure to meet production process requirements, uneven material distribution, etc., achieve simple and easy process methods, meet production process requirements, The effect of uniform cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

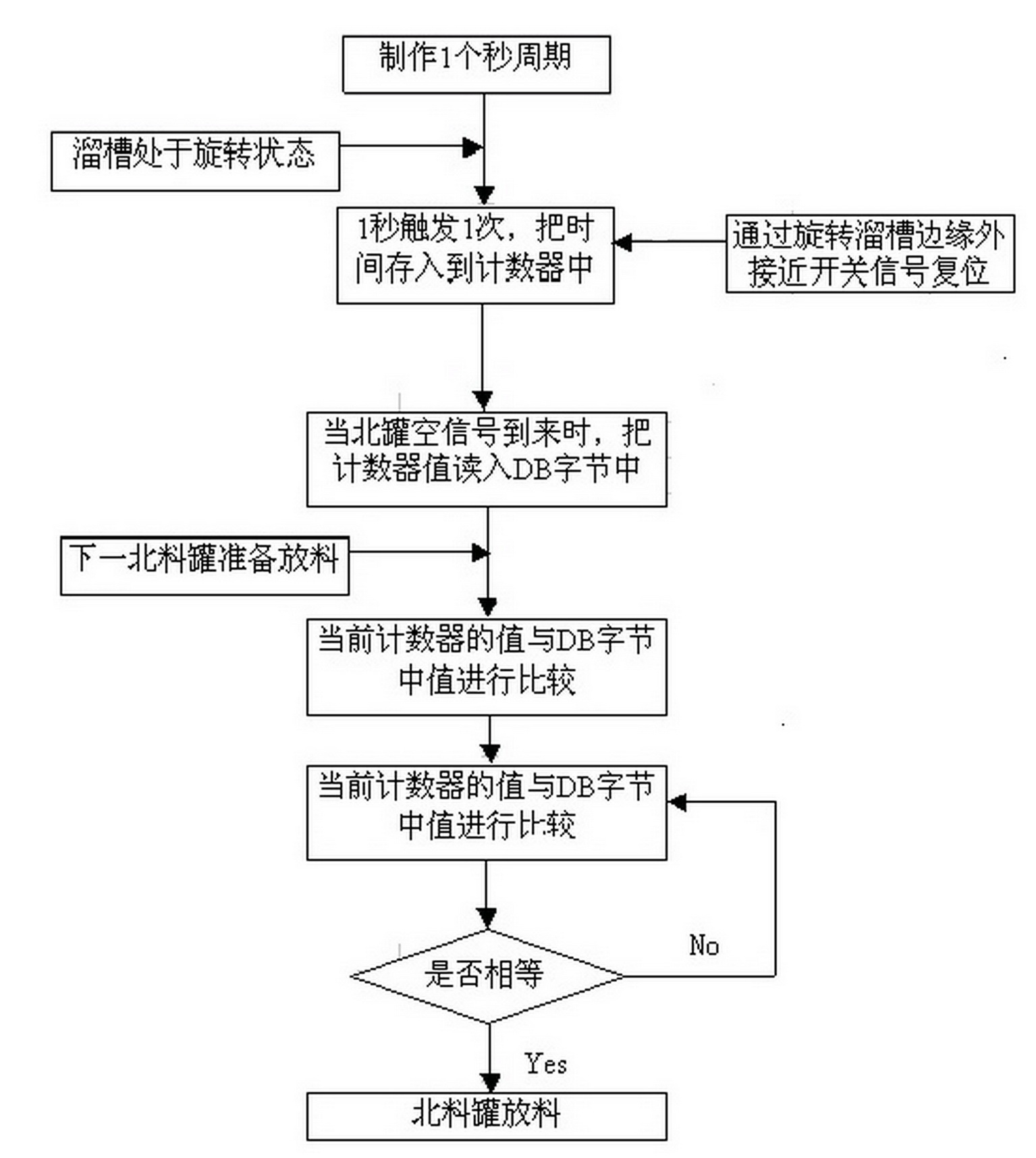

[0009] A method for evenly distributing materials in a bellless blast furnace, such as figure 1 As shown, taking the 380 bellless blast furnace fabric as an example, the method includes the following steps: 1. First, install and fix a proximity switch outside the edge of the planetary gearbox? The center of the turbine in the communication device is welded with an extended iron rod, and an iron stopper is welded at the outer end of the iron rod, and the proximity switch cooperates with the iron stopper. When the iron stop rotates to the position of the proximity switch, the proximity switch acts and sends out a corresponding position signal. 2. Add a second cycle program segment in the blast furnace material distribution control program. The second cycle is triggered once per second to count the second cycle; 3. During the production process, the running time of the rotary chute is continuously stored in the specified In the counter, detect the proximity switch signal outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com