Polyester resin for beta-hydroxyalkylamide low temperature curing weather-resistant powder paint and preparation method thereof

A technology of hydroxyalkylamide and powder coatings, which is applied in powder coatings, polyester coatings, coatings, etc., and can solve the problem of high acid value of polyester resins and low-temperature curing of β-hydroxyalkylamide polyester resins. , poor weather resistance and other issues, to achieve good aging performance, good anti-thick film pinhole performance, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

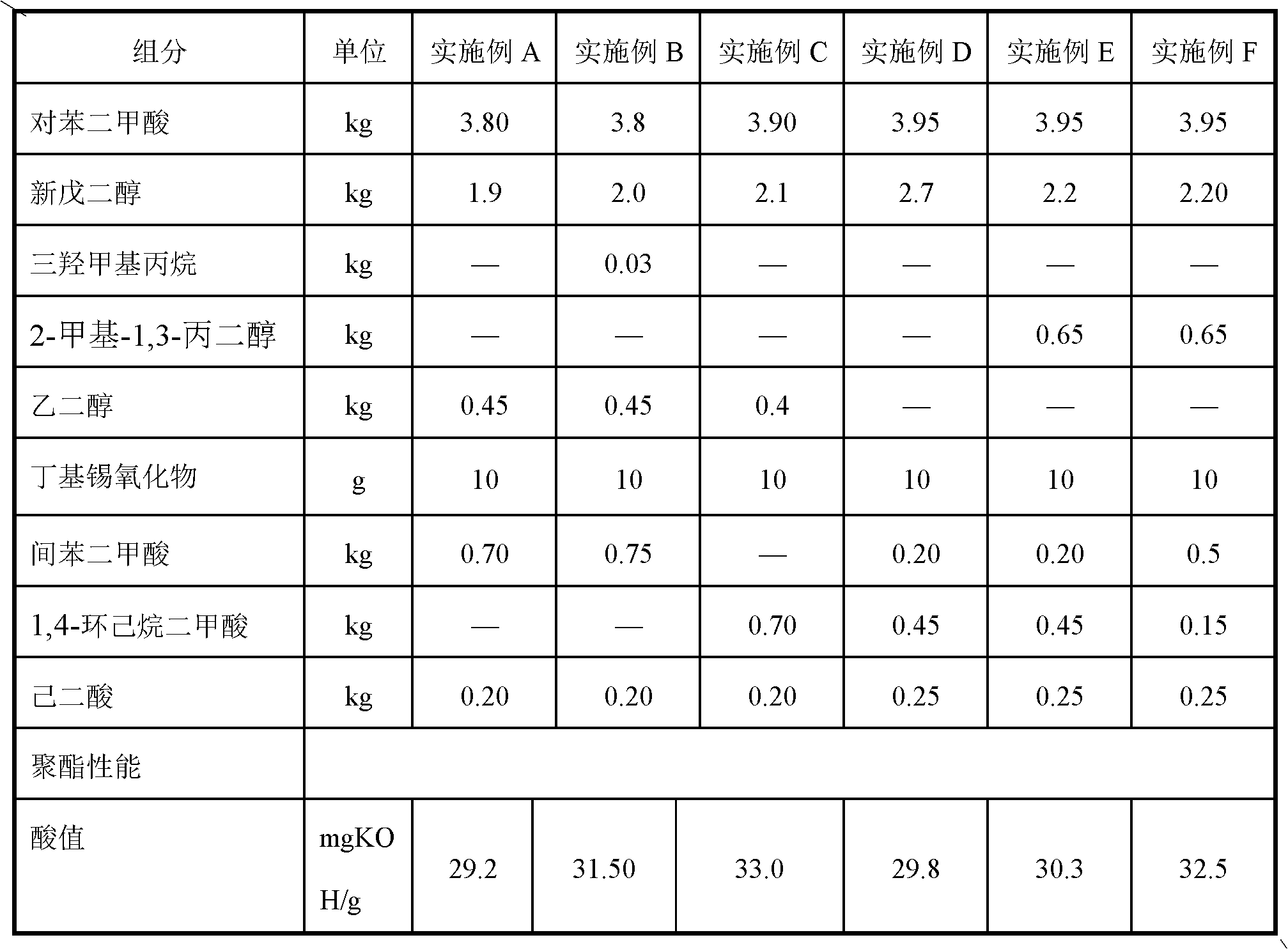

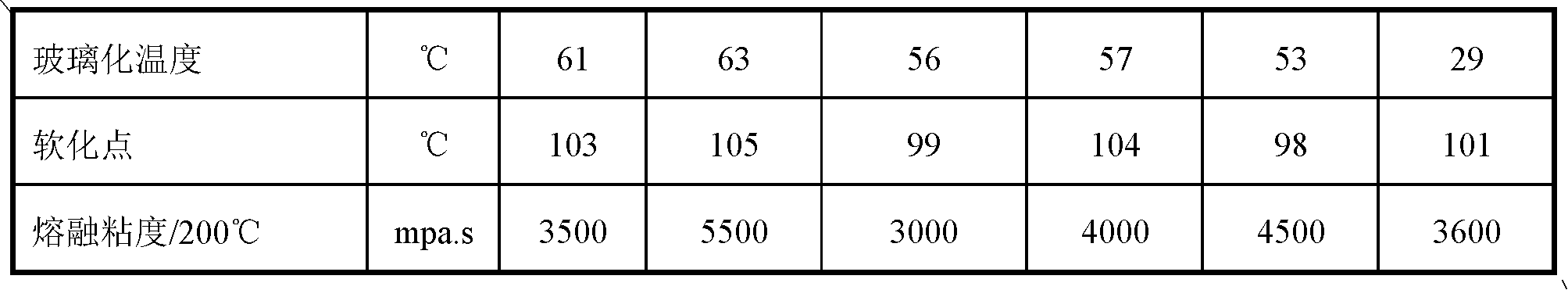

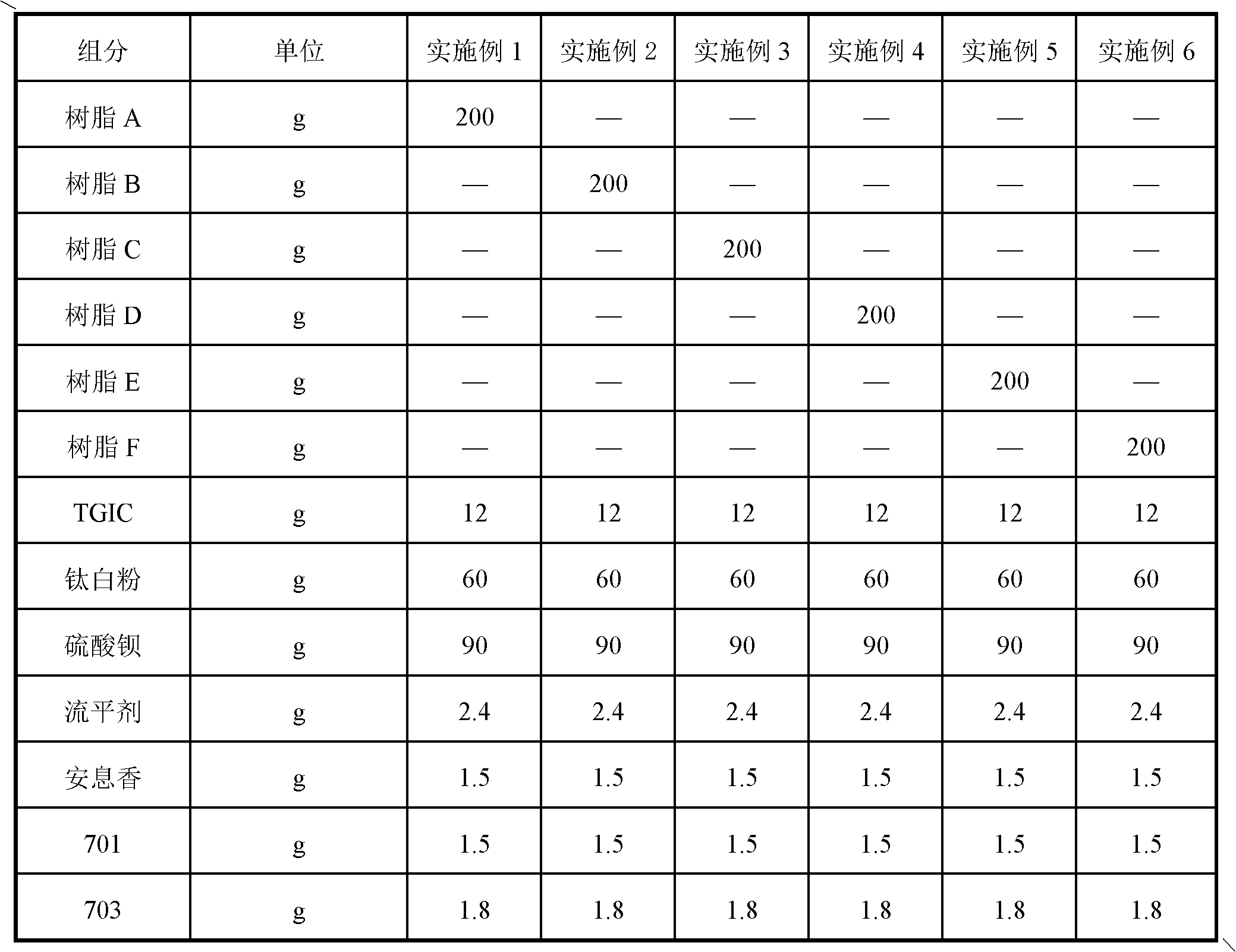

[0027] Some specific examples are enumerated below to illustrate the present invention. Table 1 shows examples of polyester resins, and A to F show comparative examples of different monomers and process combinations. In a 10-liter reactor, add neopentyl glycol, 2-methyl-1,3-propanediol, ethylene glycol, and trimethylolpropane in proportions listed in Table 1, and heat up to material melting; then Add terephthalic acid, adipic acid, butyl tin oxide, 1,4-cyclohexanedicarboxylic acid, and continue to heat up the reaction with nitrogen gas. At about 180°C, esterification water begins to be formed and distilled out, and then the temperature is gradually raised to 250°C. React for 5-10 hours until 95% of the esterification water is discharged, and the acid value reaches 10-20 mgKOH / g, add an acidolysis agent and continue the reaction for 3-5 hours until the acid value reaches 40-50 mgKOH / g, then vacuumize and polycondense for about 1 ~4h, until the acid value reaches 28~36mgKOH / g, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com