Manufacturing method of sandwich plate

A production method and multi-layer board technology, which is applied in the field of copper clad laminates and printed circuit boards, can solve the problems of large glue flow on the pressing board, and achieve the effect of avoiding high cost, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

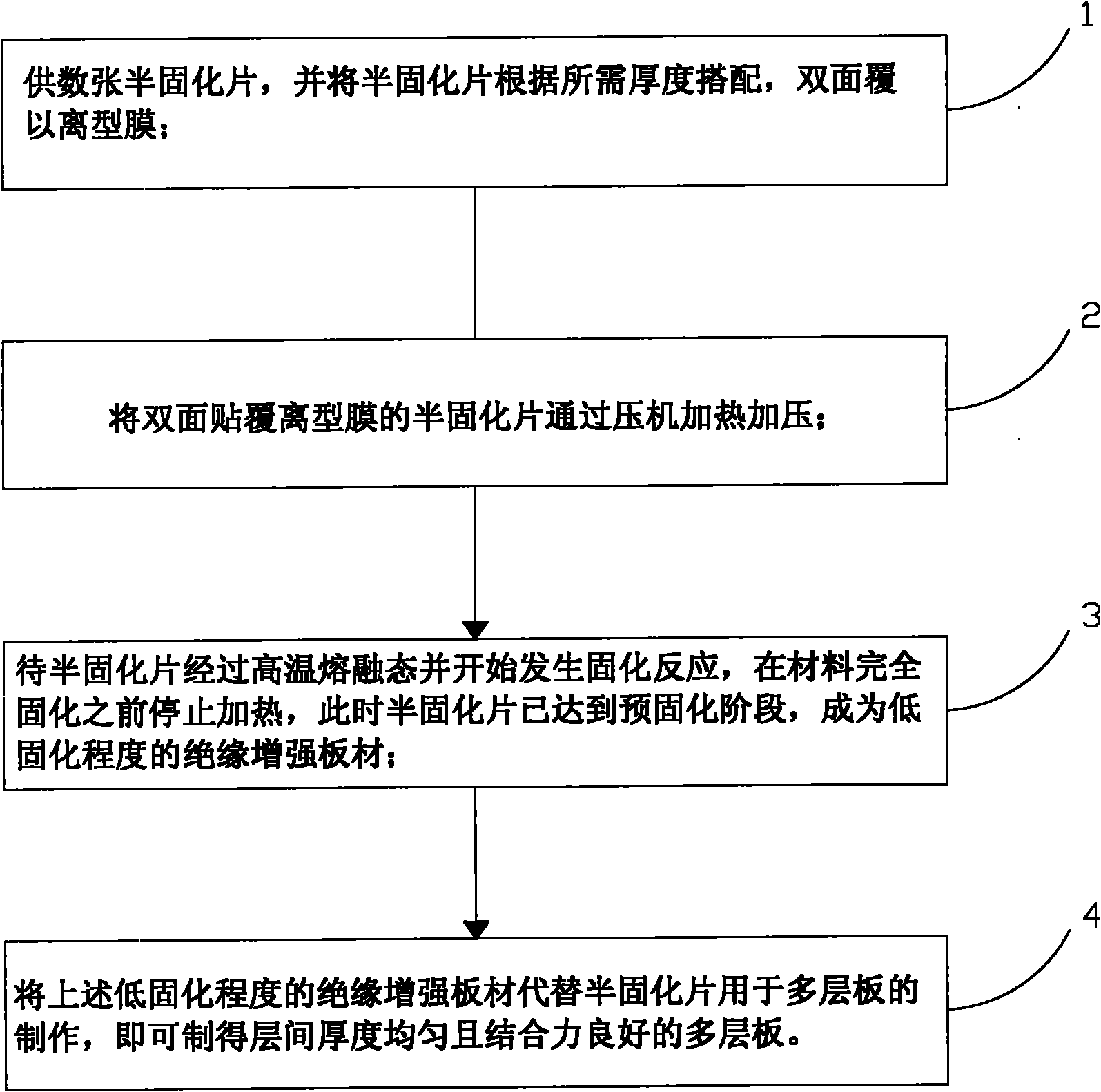

[0026] Such as figure 1 As shown, the present invention provides a kind of manufacturing method of multi-layer board, and it comprises the steps:

[0027] Step 1. Provide several prepregs, match the prepregs according to the required thickness, and cover both sides with a release film. As an optional embodiment of the present invention, the prepreg can be a 7628 prepreg impregnated with FR-4 resin mixture.

[0028] Step 2. Heat and press the prepreg coated with release film on both sides by a press. In step 2, the prepreg can be heated and pressed by a vacuum press.

[0029] Step 3. After the prepreg passes through the high-temperature molten state and begins to undergo a curing reaction, stop heating before the material is completely cured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com