Method for testing welding quality of electro-fusion joint and realizing automatic evaluation

An electric fusion joint and welding quality technology, which is applied in the field of electric fusion welding of plastic pipes or plastic composite pipes, can solve the problems of joint welding quality inspection and evaluation methods without welding process, and achieve the effect of avoiding the interference of human factors and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation method of the present invention will be described in detail below in conjunction with specific implementation examples.

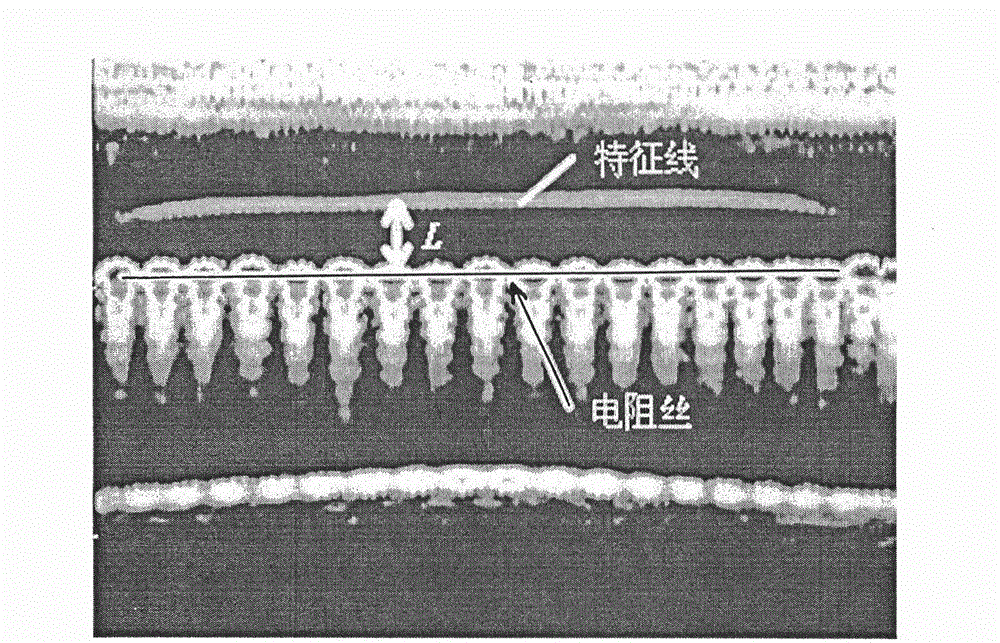

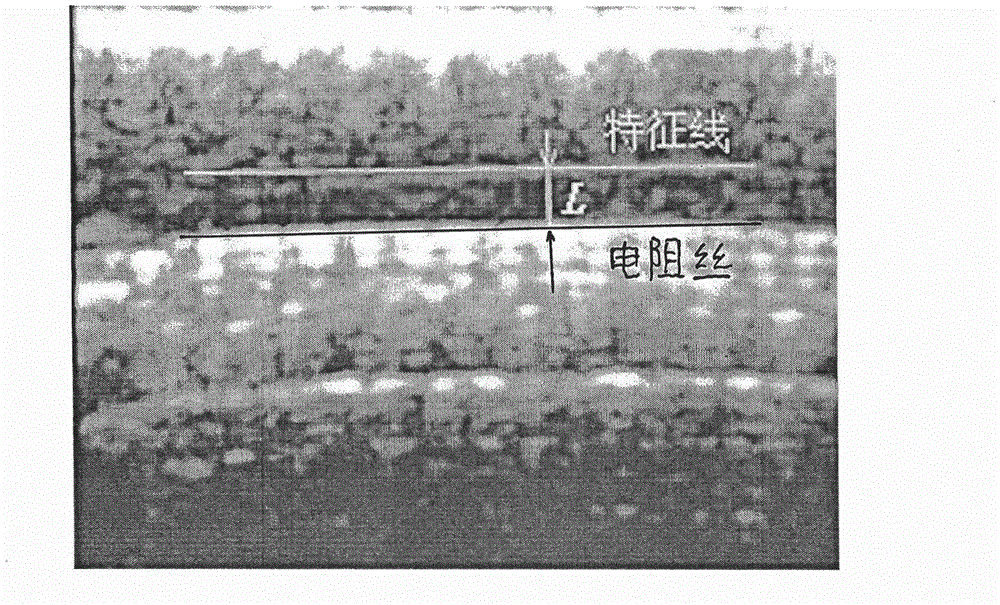

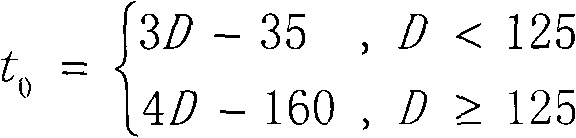

[0041] In the present invention, the peeling energy per unit area E p And the distance L between the characteristic line and the resistance wire is realized through a tensile peel test and an ultrasonic phased array B-scan section imaging test. Determination of the peeling energy per unit area E of the welded interface by tensile peeling test p , according to the size of the peeling energy per unit area and the failure position of the peeled sample to judge whether the joint welding interface has reached the best mechanical properties. The ultrasound image of the section of the electrofusion joint can be obtained through the ultrasonic phased array B-scan cross-sectional imaging test, and the sound emission intensity of the ultrasonic testing instrument is gradually increased until the echo signals of the resistance wire and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com