Method and assembly for filtering water, in particular ultrafiltration method

A filtration system and water filtration technology, applied in chemical instruments and methods, ultrafiltration, water distribution pipes, etc., can solve problems such as inability to produce filtrate, and achieve the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

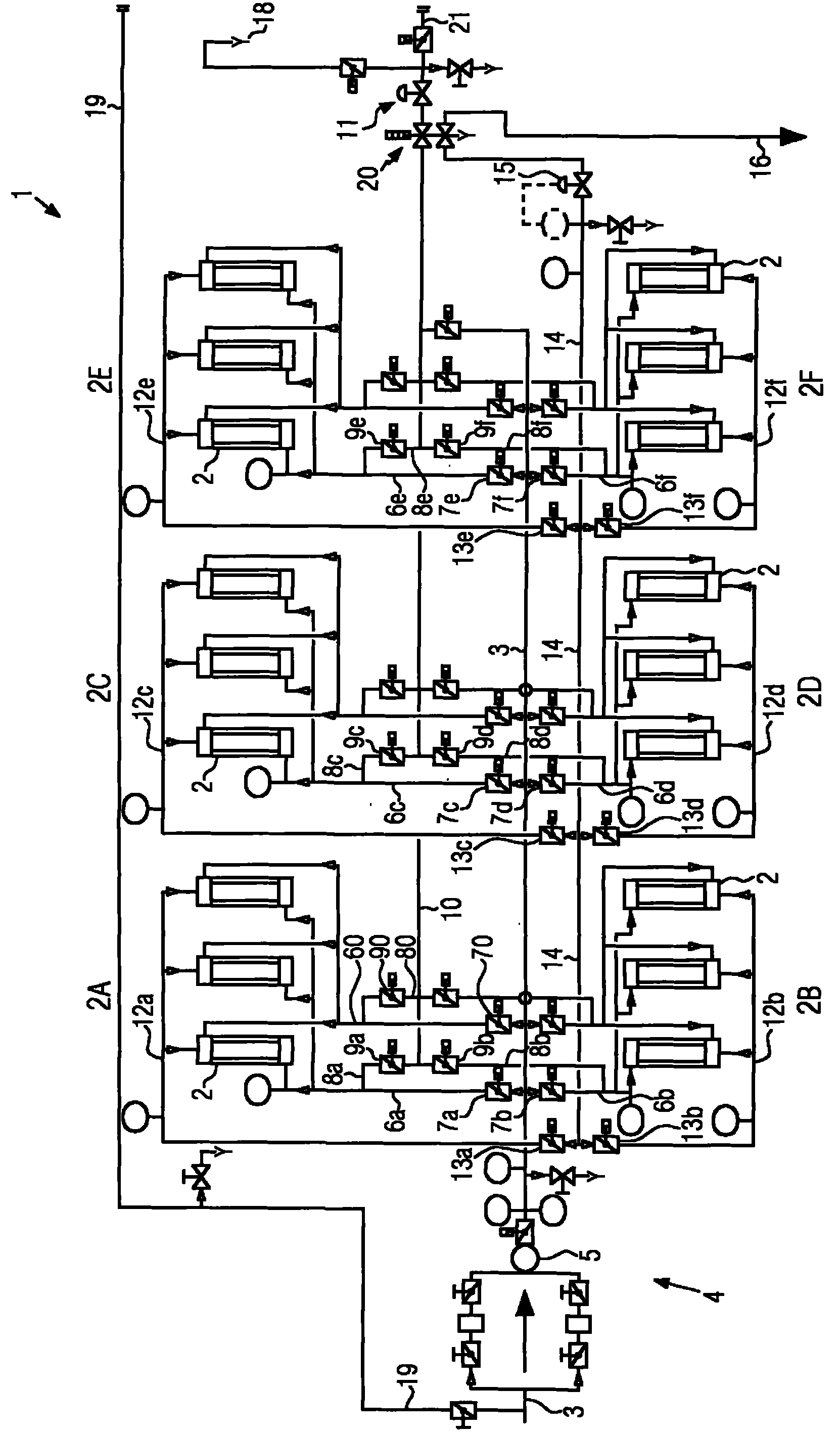

[0016] An embodiment of the invention is explained in more detail below with the sole figure showing a schematic flow diagram of a filter system according to the invention.

[0017] The shown filtration system 1 is an ultrafiltration system comprising a plurality of filtration modules 2 each comprising a bundle of hollow fibers through which filtration is performed through the walls of the hollow fibers. Throughout the system, the filter modules 2 are substantially identical and perform the same functions. The filter modules 2 are combined into groups 2A, 2B, 2C, 2D, 2E and 2F. Each of the groups 2A-2F preferably comprises the same number of filter modules 2, whereby, in the embodiment shown, 3 filter modules 2 are provided for each of the groups 2A-2F. However, the number of filter modules can vary according to requirements, and in extreme cases, each group can also comprise only one filter module.

[0018] The water to be treated is supplied to the filter module 2 via line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com