Protective feed acidifier and processing method thereof

A feed acidifier and protective technology, applied in the field of protective feed acidifier and its processing, can solve the problems of low melting point effective components, affecting the secretion of gastric acid and pepsin, reducing the nutritional titer in the feed, etc. And lost, guaranteed health and integrity, cleverly designed unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

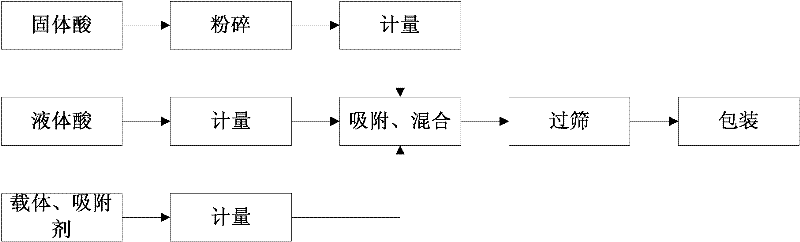

Method used

Image

Examples

example 1

[0084] Acidifier formula: 40% (by weight) phosphoric acid (commercially available, food grade), 12% (by weight) lactic acid (commercially available, food grade), 18% (by weight) stearic acid (commercially available, food grade) , And 30% (weight) of 20-60 mesh white carbon black.

[0085] The processing is carried out according to the above processing method, wherein the liquid acid is phosphoric acid and lactic acid, the adsorbent and auxiliary materials are white carbon black, and the coating material is stearic acid.

example 2

[0087] Acidifier formula: 41% (by weight) phosphoric acid (commercially available, food grade), 20% (by weight) lactic acid (commercially available, food grade), 13% (by weight) stearic acid (commercially available, food grade) , And 26% (weight) of 20-60 mesh white carbon black.

[0088] The processing is carried out according to the above processing method, wherein the liquid acid is phosphoric acid and lactic acid, the adsorbent and auxiliary materials are white carbon black, and the coating material is stearic acid.

example 3

[0090] Acidifier formula: 50% (by weight) phosphoric acid (commercially available, food grade), 13% (by weight) lactic acid (commercially available, food grade), 12% (by weight) stearic acid (commercially available, food grade) , And 25% (weight) of 20-60 mesh white carbon black.

[0091] The processing is carried out according to the above processing method, wherein the liquid acid is phosphoric acid and lactic acid, the adsorbent and auxiliary materials are white carbon black, and the coating material is stearic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com