Quaternary phosphonium salt bactericide supported on silica gel as well as preparation and application thereof

A bactericide and silica gel technology, applied in silica gel immobilized quaternary phosphonium salt fungicides and its preparation and application fields, can solve the problems of high cost, large environmental pollution, etc., and achieve easy operation, low dosage, low toxicity and pH value adaptation range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

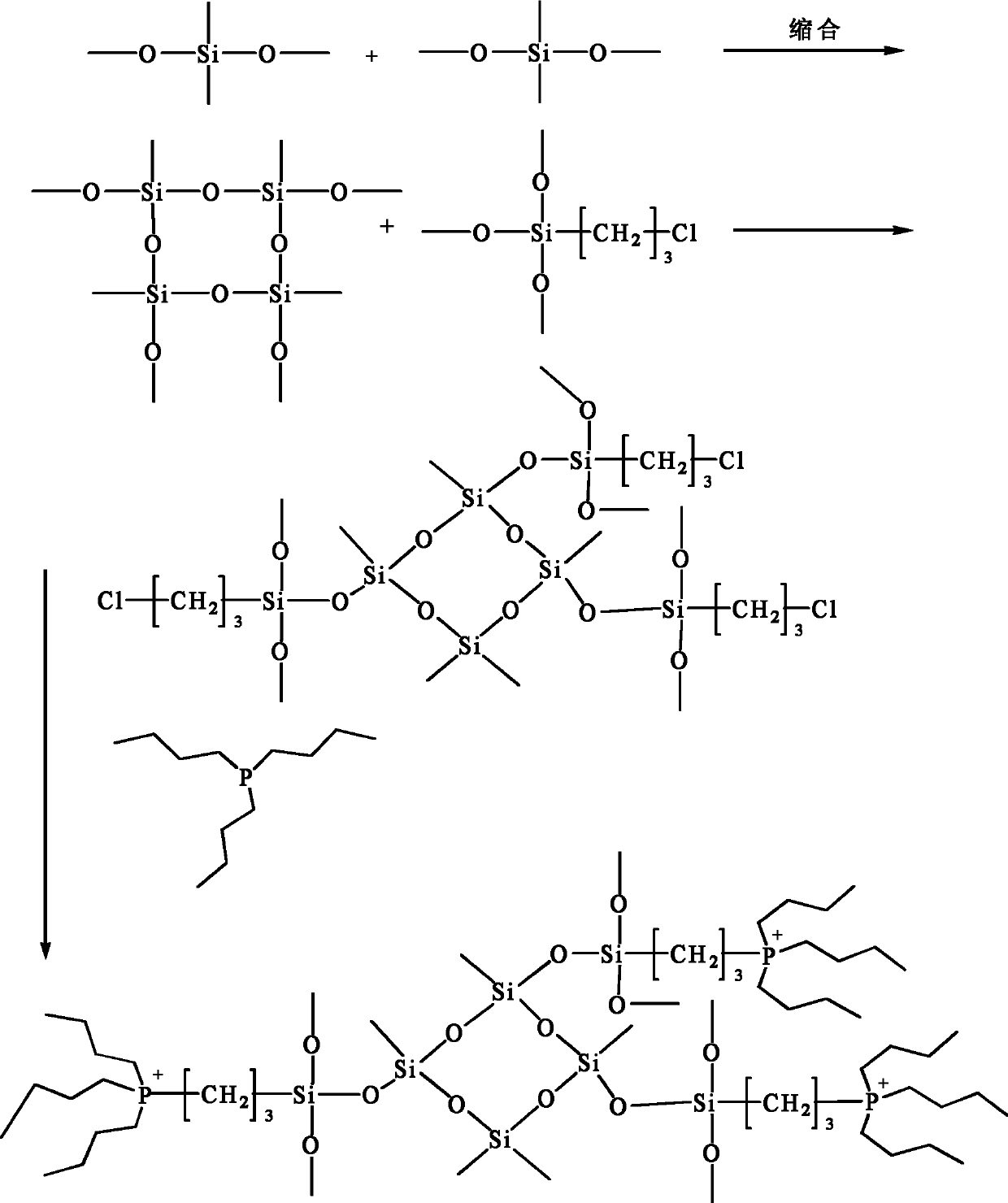

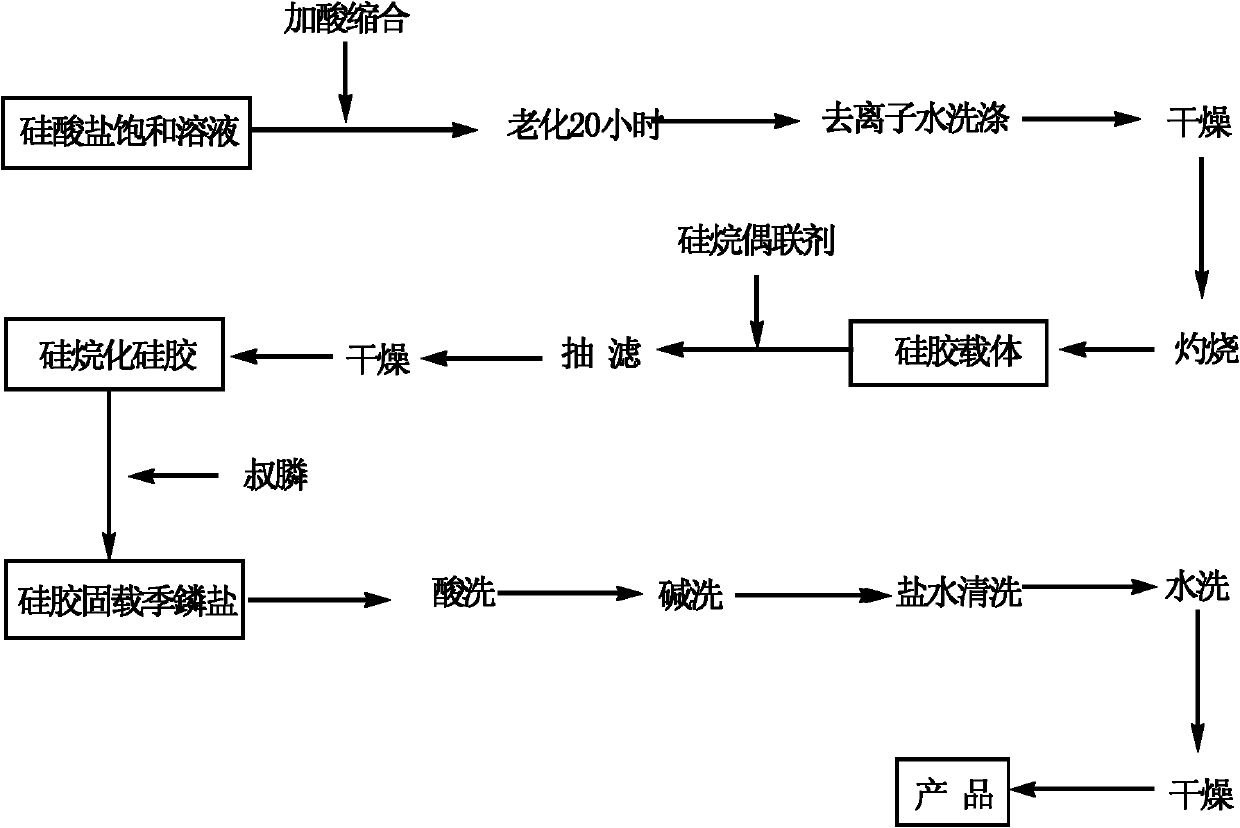

Method used

Image

Examples

Embodiment 1

[0039] Take the saturated solution in step 101 as a saturated ethyl silicate solution with a modulus of 2;

[0040] The acid in step 102 is acetic acid;

[0041] Take the silica gel aging temperature in step 103 as 80°C, and the aging time as 12 hours;

[0042] Take the silica gel drying temperature in step 104 as 100°C, the drying time is 15 hours, and the silica gel powder is ground to 60 mesh;

[0043] The sintering temperature of the silica gel powder in step 105 is 600°C, and the sintering time is 8 hours;

[0044] Taking the haloalkylsiloxane in step 106 as 0.8 parts of γ-chloropropyltrimethoxysilane, the temperature is controlled to 80°C, and the reaction time is 18 hours;

[0045] The tertiary phosphine compound in step 107 is tributylphosphine, the stirring time of intermediate product A is 40 hours, and the drying temperature of intermediate product C is 60°C.

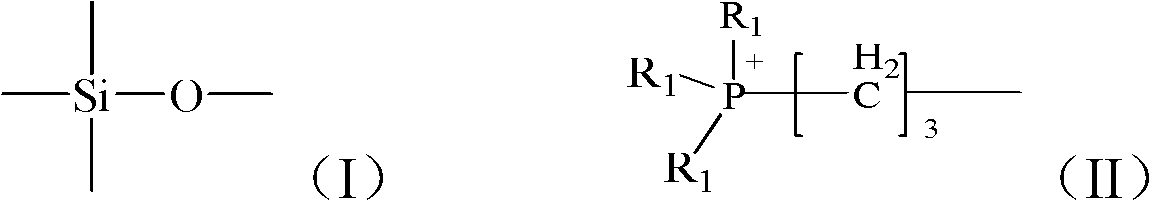

[0046] The structure of the bactericide 1 is:

[0047]

Embodiment 2

[0049] Take the saturated solution in step 101 as a saturated ethyl silicate solution with a modulus of 2.5;

[0050] Take the acid in step 102 as hydrochloric acid;

[0051] Take the aging temperature of the silica gel in step 103 as 90°C, and the aging time as 20 hours;

[0052] Take the silica gel drying temperature in step 104 as 120°C, the drying time as 20 hours, and grind the silica gel powder to 70 mesh;

[0053] The sintering temperature of the silica gel powder in step 105 is 700°C, and the sintering time is 10 hours;

[0054] Take the haloalkylsiloxane in step 106 as 1.2 parts of γ-chloropropyltriethoxysilane, control the temperature at 90°C, and the reaction time at 20 hours;

[0055] Take the tertiary phosphine compound triphenylphosphonium in step 107, the stirring time of intermediate product A is 48 hours, and the drying temperature of intermediate product C is 70°C.

[0056] The structure of the fungicide 2 is:

[0057]

Embodiment 3

[0059] Take the saturated solution in step 101 as a water glass saturated solution, with a modulus of 2;

[0060] The acid in step 102 is nitric acid;

[0061] Take the silica gel in step 103 when the temperature is 85°C during aging, and the aging time is 16 hours;

[0062] Take the silica gel drying temperature in step 104 as 110°C, the drying time is 17 hours, and the silica gel powder is ground to 80 mesh;

[0063] The sintering temperature of the silica gel powder in step 105 is 650°C, and the sintering time is 9 hours;

[0064] Take the haloalkylsiloxane in step 106 as 0.9 parts of γ-chloropropylmethyldimethoxysilane, control the temperature to 85°C, and the reaction time to be 19 hours;

[0065] The tertiary phosphine compound in step 107 is trioctylphosphine, the stirring time of intermediate product A is 44 hours, and the drying temperature of intermediate product C is 65°C.

[0066] The structure of the fungicide 3 is:

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com