Biomass conveying installation for feeding into a pressurised container

A pressure vessel, biomass technology, applied in the direction of conveying bulk materials, conveyors, presses, etc., can solve the problems of inability to realize biomass, high production costs, etc., and achieve the effect of avoiding blockage or looseness and large cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

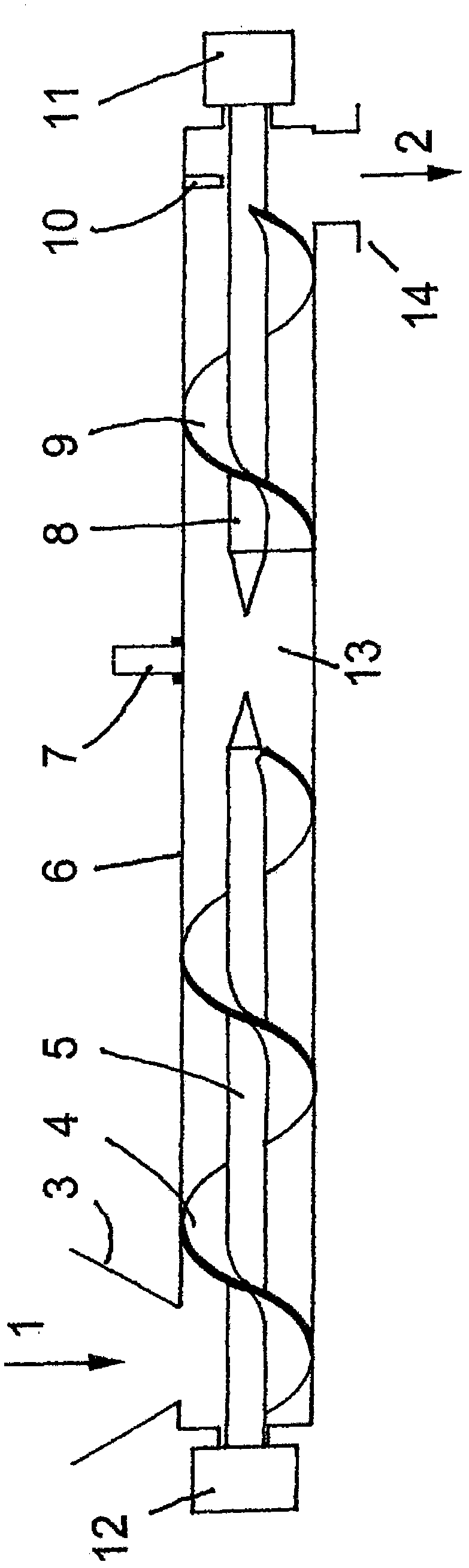

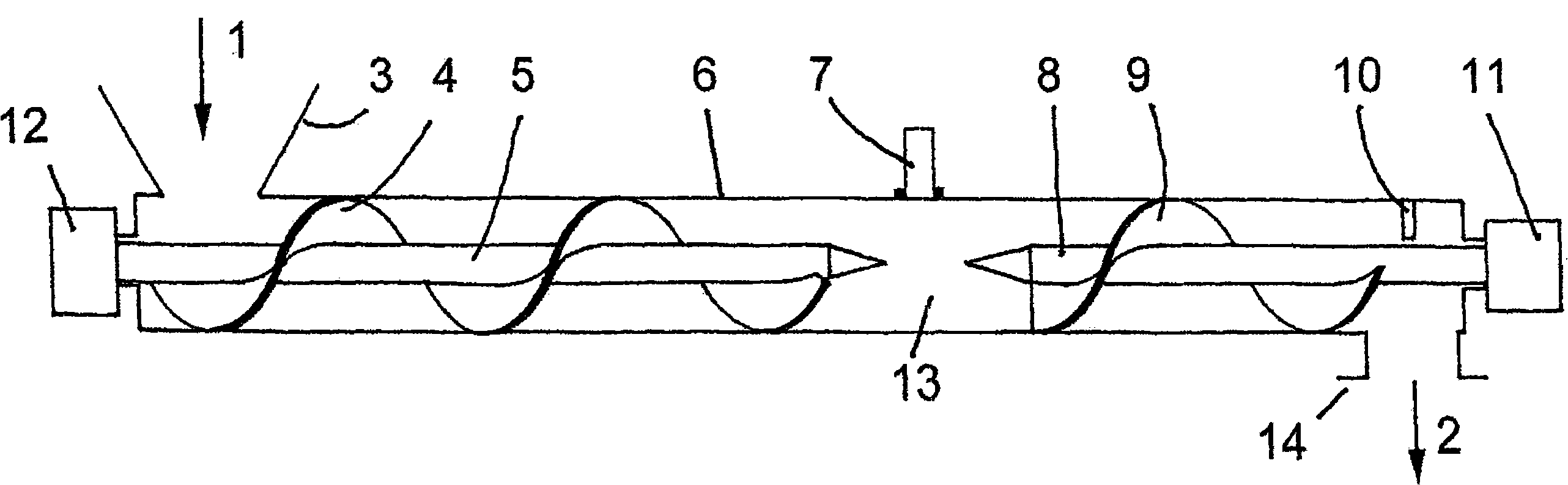

[0023] The biomass 1 is fed at the funnel 3, for example by a receiver with a swivel guide, and leaves the conveying device at the outlet 2 via the flange 14, which is connected to a container or The next level of conveying device is connected. The biomass 1 first flows through the main screw conveyor, which consists of a screw duct 6 , a screw shaft 5 and a screw flight 4 . The biomass 1 is then conveyed through a pipe section 13 without any conveying components. The plunger body made of biomass formed in this pipe section 13 is conveyed further into a secondary screw conveyor, which is formed from a spiral pipe 6 , a screw shaft 8 and a screw flight 9 . At the end of the conveying stroke, the biomass enters an overpressurized space at the outlet 2 . It has proven to be advantageous to arrange a passive or active cutting device 10 at the end of the transport path.

[0024] The rotational speed of the main screw conveyor driven by the motor 12 largely determines the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com