Method for separating sapphire substrate by unit on basis of stress action

A sapphire substrate, stress-action technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of low yield of laser lift-off, and achieve the effect of ensuring unit independence and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] A method for separating a sapphire substrate unit by unit based on stress, the preparation steps are as follows:

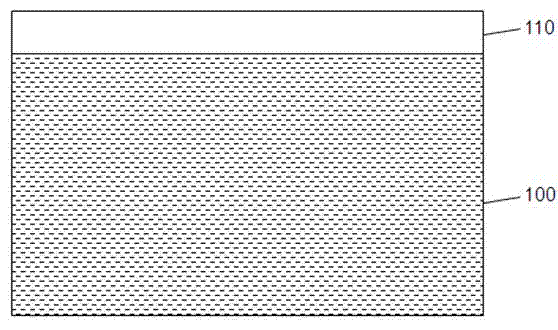

[0025] Such as figure 2 As shown, an N-type GaN-based semiconductor layer, an active layer and a P-type GaN-based semiconductor layer are epitaxially grown sequentially on a sapphire substrate 100 by metal organic chemical vapor deposition (MOCVD) to form a GaN-based epitaxial thin film 110 .

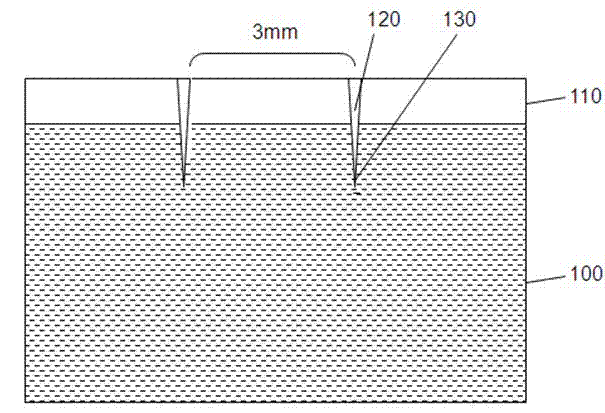

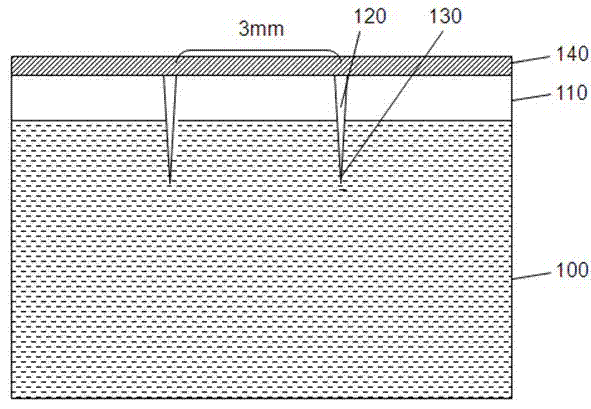

[0026] Such as image 3 As shown, a laser scribing machine (wavelength 355nm) is used to slit the GaN-based epitaxial film 110 and extend it to the sapphire substrate 100. The scribing is carried out in an orthogonal (X-Y axis) manner with a period of 3mm×3mm, and the set The size of the laser lift-off spot is similar, and the depth of laser scribing is 30 microns, that is, to realize the unitization of GaN-based epitaxial thin films, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com