Three-dimensional light-emitting led chip filament and led bulb

A technology of LED chips and filaments, which is applied to semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of affecting the quality of the lamp body, difficult to fix the leads, difficult to weld and connect, etc. The effect of simplifying the stand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

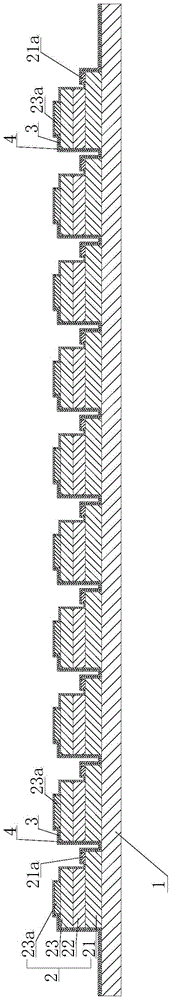

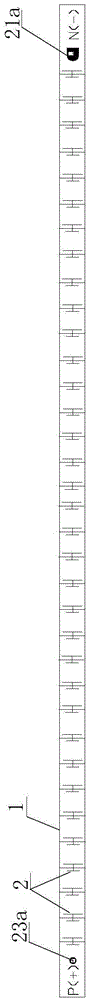

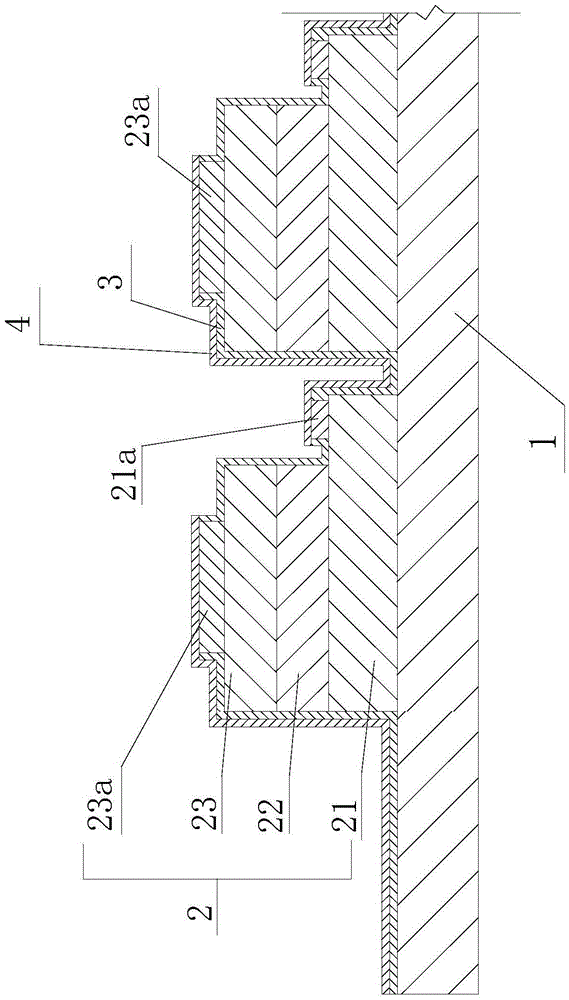

[0025] Such as Figure 1 to Figure 6 Shown: a filament of a three-dimensional light-emitting LED chip, including a strip-shaped transparent support 1 and a number of split diode light emitters 2 along the transparent support 1, the transparent support 1 constitutes the support of the whole chip, and the split diode light emitters 2 includes an N-GaN layer 21, an MQW light-emitting layer 22, and a P-GaN layer 23 stacked in sequence, an N electrode 21a is provided on the surface of the N-GaN layer 21, a P electrode 23a is provided on the surface of the P-GaN layer 23, and a P-electrode 23a is provided on the surface of the N electrode 21a and the surface of the split diode light emitter 2 at the P electrode 23a are provided with SiO 2 Passivation layer 3, on the upper surface of N electrode 21a and P electrode 23a on the opposite SiO 2 An exposed conduction window is formed at the passivation layer 3, SiO 2 The passivation layer 3 is covered with a metal circuit to connect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com