Production facility and process for super-low tensibility poly V-belt cord

A production process and production equipment technology, applied in the field of transmission belts, can solve the problems of increased use cost and inconvenient use, and achieve the effects of reduced elongation, convenient use, and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

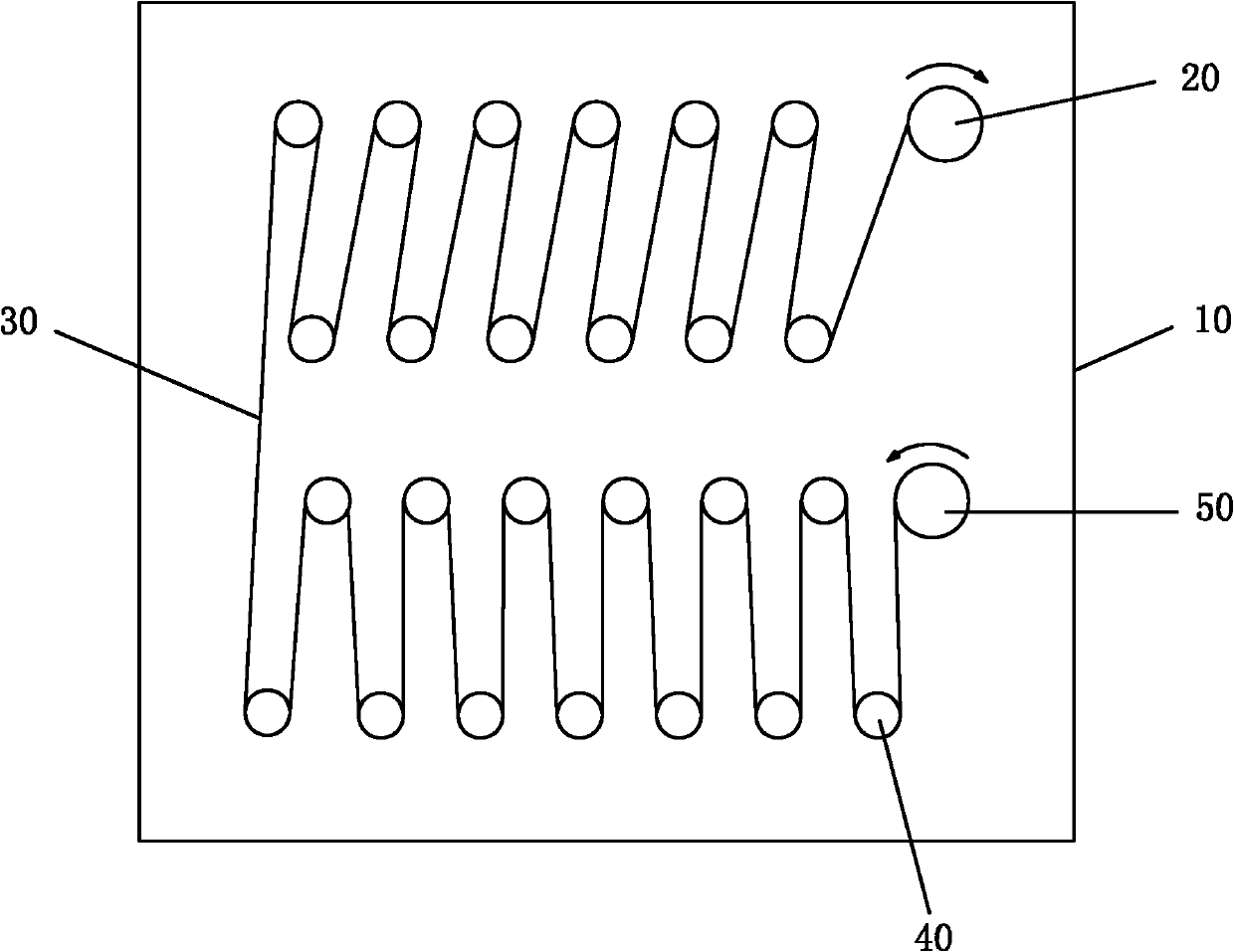

[0018] The present invention will be further described below with specific embodiment, see figure 1 :

[0019] The production equipment of ultra-low-stretch poly-V-belt wire rope is provided with a stretching device in the oven 10. The stretching device is: two sets of stretching wheels 40 are arranged around or front and back to form a stretching wheel group, each pulling The stretching wheel group is made up of about 10-25 stretching wheels 40 arranged in two rows or front and back, and a tension controller is arranged between the stretching wheel groups to control the tension of the wire rope 30 between the stretching wheels. The front portion of the stretching wheel set is provided with a pay-off wheel 50 or a take-up wheel 20, and the rear portion of another group of stretching wheel sets is provided with a take-up wheel 20 or a pay-off wheel 50, and a driving pulley is provided on the take-up wheel 20. Stretching wheel, pay-off wheel 50 and take-up wheel 20 rotate power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com