Centrifugal screen

A centrifugal sieve and sieving technology, applied in the field of centrifugal sieves, can solve the problems of large space in the sieving cabin, difficulty in controlling the conveying force, direct movement to the discharge port, etc., and achieve the goal of improving screening efficiency, increasing output, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

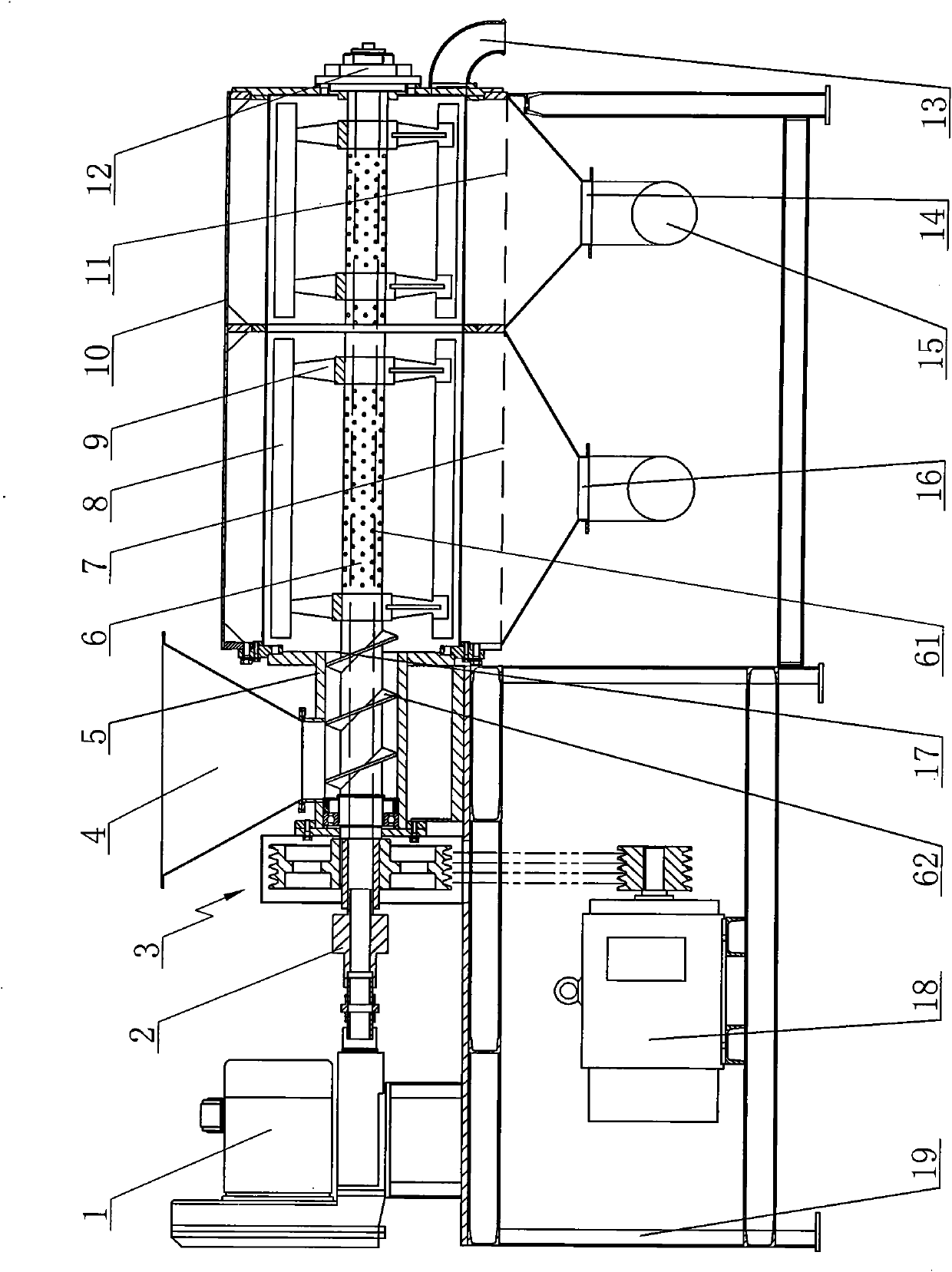

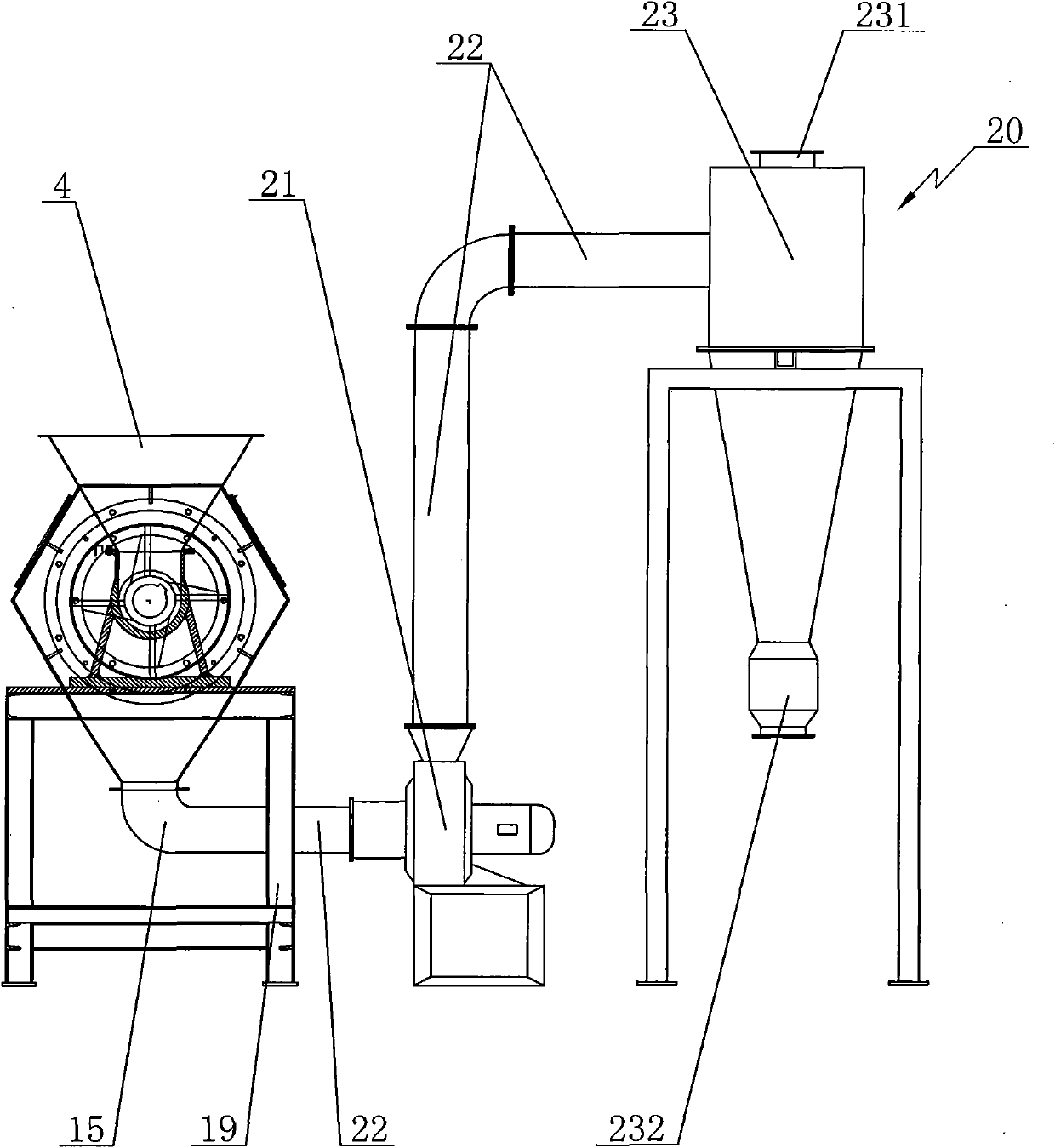

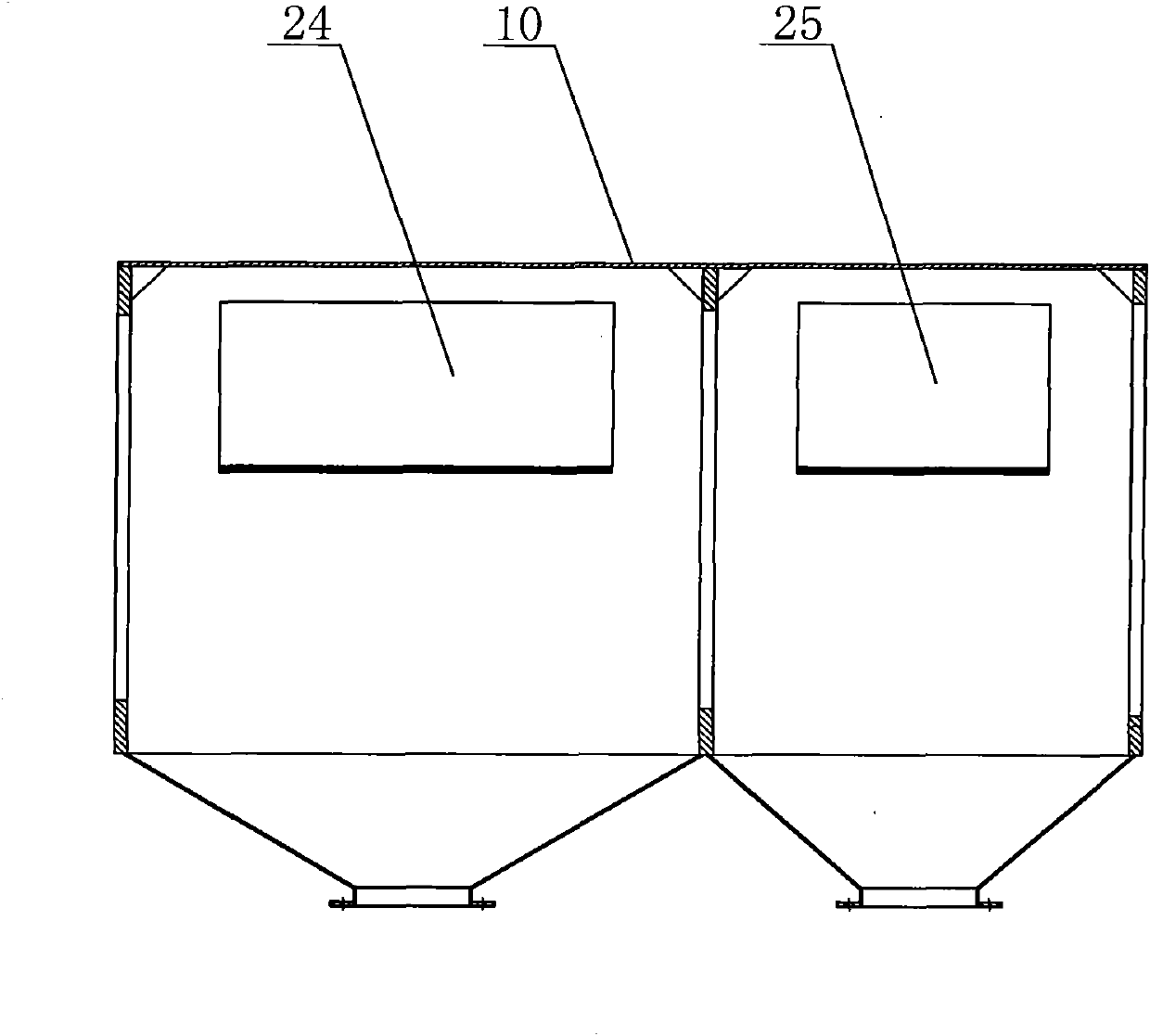

[0016] See figure 1 The present invention comprises main shaft 6 and frame 19, blower 1 and screening cabin 10 are installed on the frame 19, the left end face of screening cabin 10 is provided with feeding port 17, and the right end face of screening cabin 10 is provided with discharge port 13. The main shaft 6 is connected with the motor 18 through the belt transmission device 3, the main shaft 6 is tubular, the left end of the main shaft 6 is connected with the blower 1 through the rotary joint 2, the main shaft 6 passes through the feeding port 17 and the screening cabin 10, and the right end of the main shaft 6 passes through the bearing The seat 12 is connected with the right end face of the screening cabin 10 . The feeding pipe 5 is connected to the left end surface of the screening cabin 10 and is docked with the feeding port 17; the feeding hopper 4 is connected to the upper part of the feeding pipe 5, and the part where the left section of the main shaft 6 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com