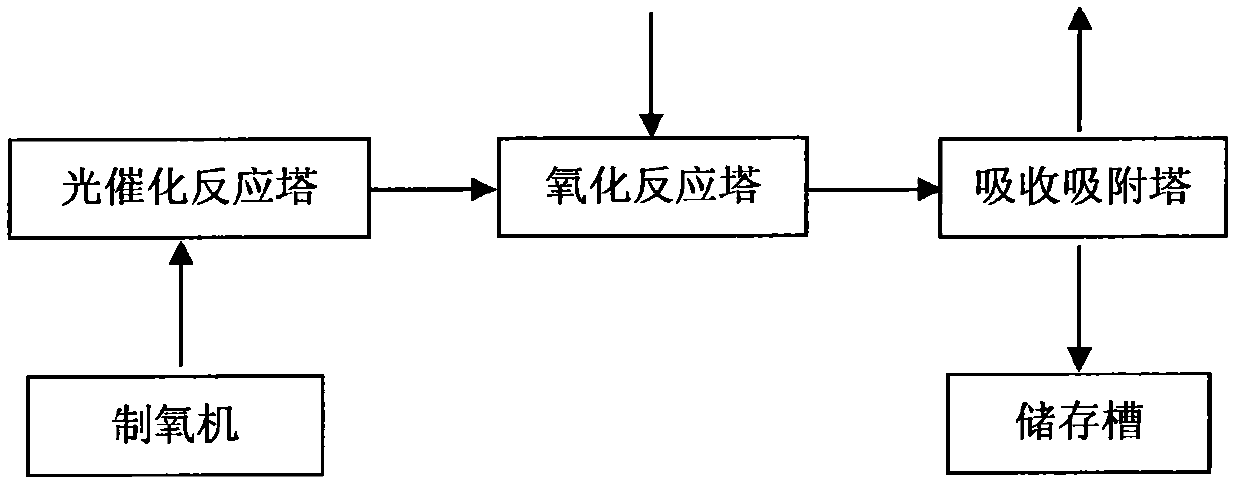

Photocatalytic oxidation flue gas desulfurization and denitration system of coal-fired power plant

A technology of photocatalytic oxidation and coal-fired power plants, which is applied in the interdisciplinary fields of energy engineering and environmental engineering, and can solve the problems of large construction investment, high operating cost, and large floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

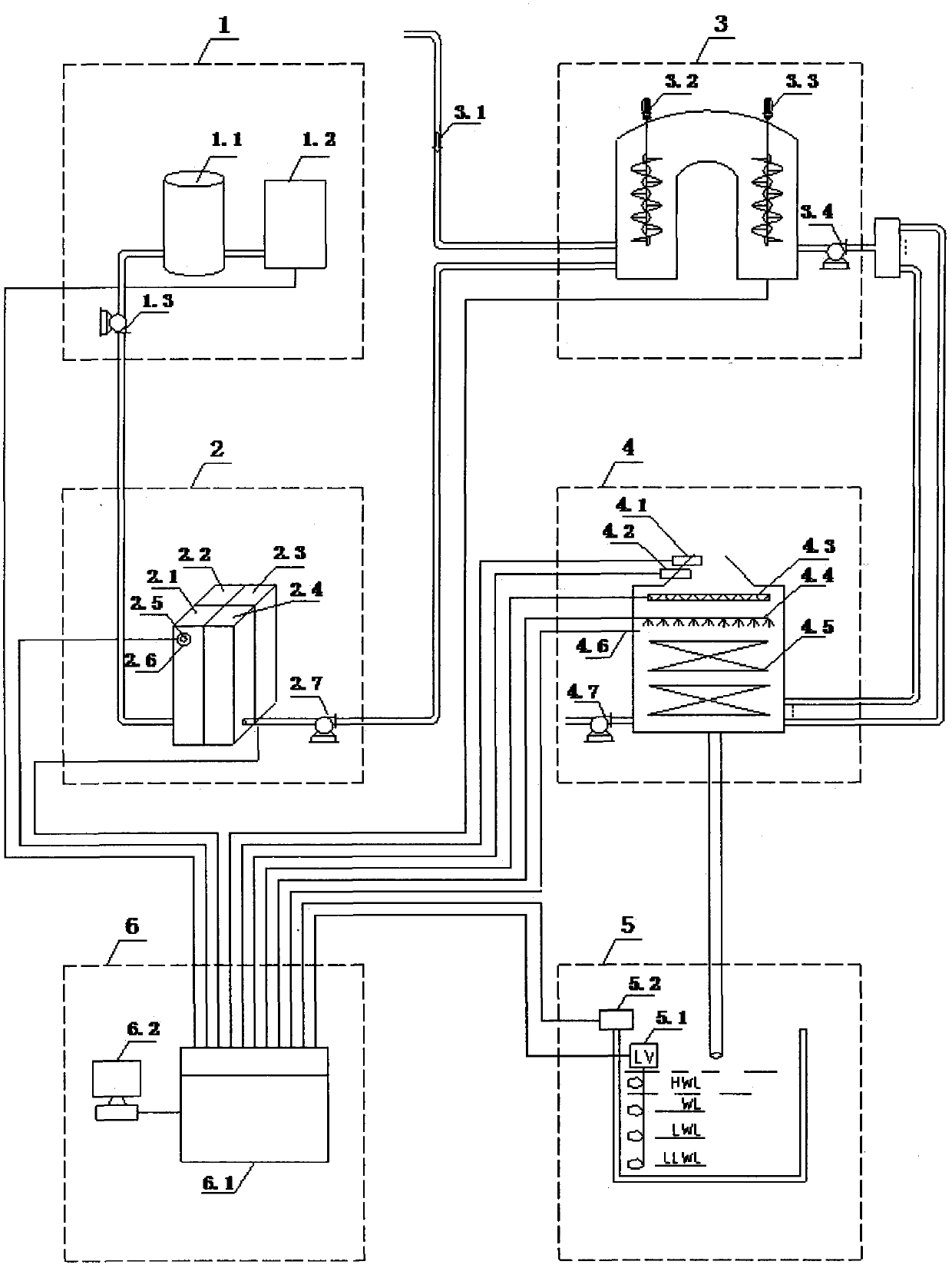

Examples

Embodiment approach

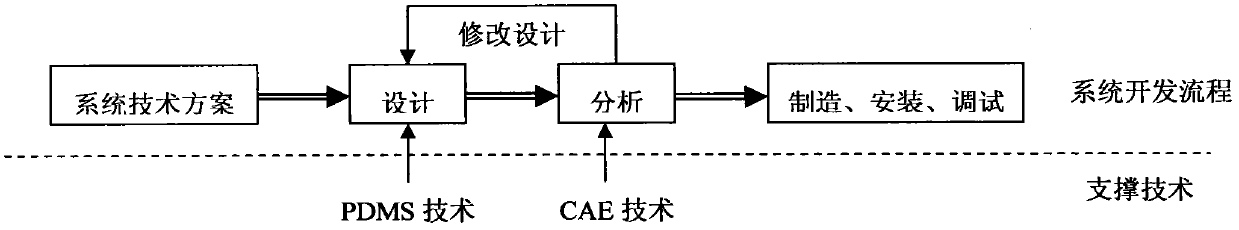

[0052] When applying the technical solution provided by the present invention to develop a complete set of equipment for the photocatalytic oxidation desulfurization and denitrification system in a coal-fired power plant, the main task is to build a PDMS-CAE collaborative development platform, and the key point is to realize the PDMS (Plant Design Management System) and CAE (Computer Aided Engineering), the development process is as follows image 3 shown. After the development platform is built, the original parameters and intermediate parameters of the flue gas (determined by theoretical calculation and experiments) are input to obtain the purchase list (direct outsourcing part), equipment manufacturing drawings and construction installation drawings. The PDMS-CAE collaborative development platform can realize the parallel collaborative design of processes, instruments, equipment, construction and installation, electrical and control, etc., and provide a common collaboration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com