Control method for aerosol in flue gas desulfurization by utilizing ammonia method and master desulfurizing tower

A control method and aerosol technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve problems such as aerosol particles that cannot condense and grow in a supersaturated water vapor environment, and solve the problem of aerosol emissions , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

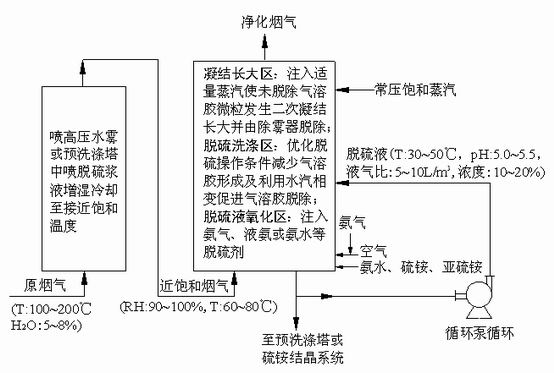

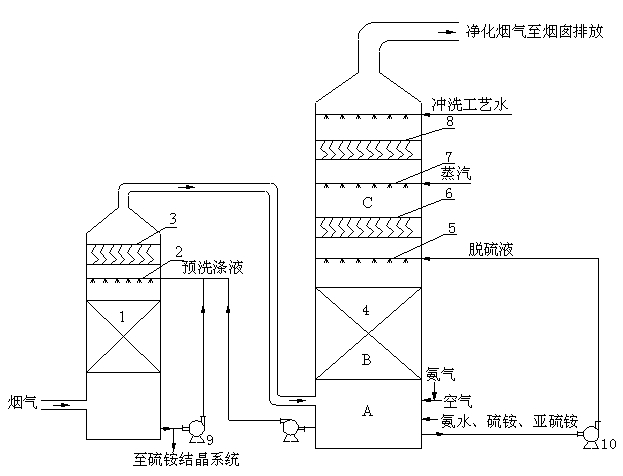

[0023] According to the present invention, a method for controlling aerosols in ammonia-based flue gas desulfurization is as follows: figure 2 As shown; the high-temperature coal-fired flue gas enters the pre-washing tower 1, and after contacting the pre-washing liquid sprayed from the pre-washing liquid nozzle 2 countercurrently from bottom to top, the temperature of the flue gas drops from 100 to 200 ° C to a temperature near the saturated dew point of 60 ~ 80°C, and then go through the pre-washing tower mist eliminator 3 to remove the water mist and then enter the desulfurization washing area B in the desulfurization main tower 4, and contact with the desulfurization liquid sprayed from the desulfurization liquid nozzle 5 countercurrently, the SO in the flue gas 2 It is mainly absorbed here; the temperature of the imported desulfurization liquid is controlled at 30~50°C, which is 20~30°C lower than the temperature of the imported flue gas, and the operating liquid-gas ratio...

Embodiment 2

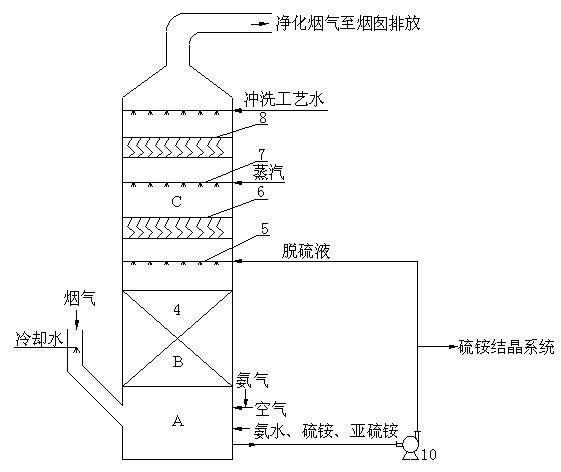

[0025] like image 3 As shown, the difference from Example 1 is that the flue gas enters the desulfurization washing zone B of the desulfurization main tower 4 after being sprayed and cooled by high-pressure water mist to a temperature close to the saturated dew point, and the rest is the same as that of Example 1.

Embodiment 3

[0027] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 150Nm 3 / h, the diameter of the desulfurization main tower is 150mm, the tower height is 2500mm, built-in four-stage spraying, the demister of the flue gas inlet in the condensation growth area is a plate corrugated demister, and the demister of the flue gas outlet is a wire mesh demister. The dust-laden flue gas produced by the coal-fired boiler enters the cooling device after the coarse particles are removed by the cyclone dust collector, and sprays high-pressure water mist with an average particle size of about 30mm. Then enter the desulfurization washing area and contact with the desulfurization liquid countercurrently. The temperature of the imported desulfurization liquid is controlled at about 31°C, and the operating liquid-gas ratio is 10L / Nm 3 , the desulfurization absorbent is ammonia water, which is added to the desulfurization oxidation zone from the bottom of the desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com