Solid flavoring and preparation process thereof

A preparation process and seasoning technology, which is applied in the field of solid seasoning and its preparation, can solve the problems of prolonged storage of ham, lipid oxidation, inconvenient use of seasoning, etc., and achieve the effects of promoting healthy development, wide application range, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

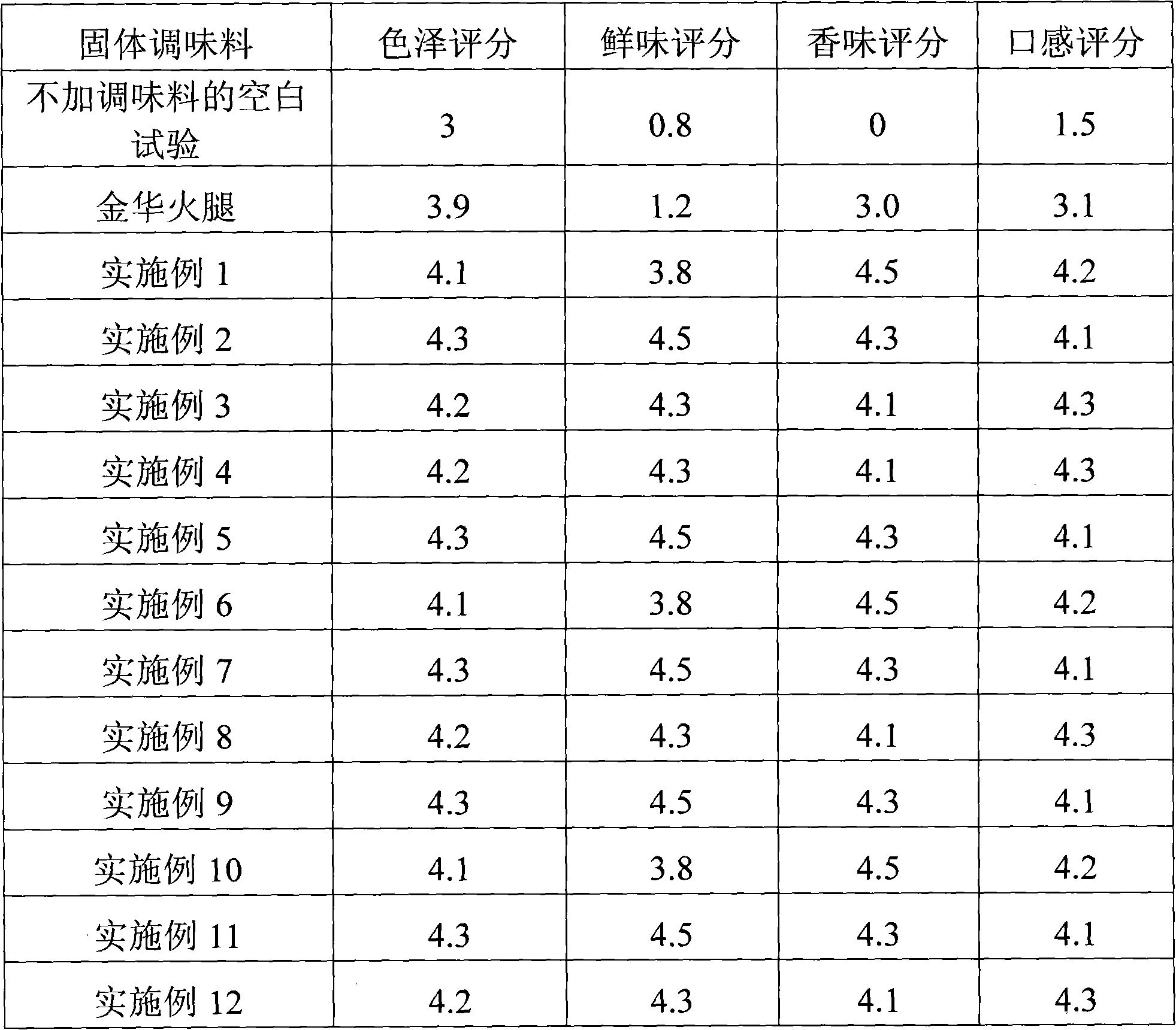

Examples

Embodiment 1

[0031] A kind of solid compound seasoning that Jinhua ham is made, its preparation technology comprises the following process steps:

[0032] (1) Weigh 50 kg of Jinhua ham, wash it, remove the bone, remove the skin and fat, cut it into pieces, put it into a stainless steel sandwich pot according to the ratio of ham meat: water = 1:1, add water to boil, boil The temperature is 90°C, and the cooking time is 3 hours. After continuously skimming off the slick oil on the surface of the soup, take out the ham meat and dry it at 100°C for 1 hour, and then use a pulverizer to make powder for later use. At the same time, crush 0.5 kg of bean paste, 26 kg of salt, 20 kg of sodium glutamate, 2 kg of white sugar, 10 kg of cornstarch, 2 kg of yeast extract, 2 kg of hydrolyzed vegetable protein and 6 kg of wheat fiber into powder for later use. .

[0033] (2) Stir and mix the raw materials pulverized by step (1) with 4 kg of water, and use a granulator to make granular semi-finished produc...

Embodiment 2

[0037] A kind of solid compound seasoning that Jinhua ham is made, its preparation technology comprises the following process steps:

[0038] (1) Weigh 40 kg of Jinhua ham, wash it, remove the bone, remove the skin and fat, cut it into pieces, put it into a stainless steel sandwich pot according to the ratio of ham meat: water = 1:1, add water to boil, boil The temperature is 95°C, and the cooking time is 2 hours. After continuously skimming off the slick oil on the surface of the soup, take out the ham meat and dry it at 80°C for 3 hours, and then use a pulverizer to make powder for later use. At the same time, crush 2 kg of bean paste, 30 kg of salt, 15 kg of sodium glutamate, 5 kg of white sugar, 6 kg of cornstarch, 8 kg of yeast extract, 8 kg of hydrolyzed vegetable protein, and 6 kg of wheat fiber into powder for later use. .

[0039] (2) Stir and mix the raw materials pulverized according to step (1) and 4 kg of water (the content is not within the maximum range indicat...

Embodiment 3

[0043] A kind of solid compound seasoning that Jinhua ham is made, its preparation technology comprises the following process steps:

[0044] (1) Weigh 29 kg (29.59%) of Jinhua ham, wash it, remove the bone, remove the skin and fat, cut it into pieces, put it into a stainless steel sandwich pot according to the ratio of ham: water = 1:1, add water and boil Boil, the boiling temperature is 80°C, and the boiling time is 5h. After skimming off the slick oil on the surface of the soup body, take out the ham and dry it at 90°C for 2h, and then use a pulverizer to make powder for future use. At the same time, 2 kg of bean paste (2.04%), 36 kg of salt (36.73%), 10 kg of sodium glutamate (10.2%), 4 kg of white sugar (4.08%), 4 kg of cornstarch (4.08%), 3 One kilogram of yeast extract (3.06%), 3 kilograms of hydrolyzed vegetable protein (3.06%), 3 kilograms of wheat fiber (3.06%) and 1 kilogram of Jinhua ham essence (1.02%) are pulverized into powder and set aside.

[0045] (2) Stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com